Articulated arm assembly

a technology of articulating arms and arm parts, applied in the direction of drilling rods, drilling pipes, drilling casings, etc., can solve the problems of tripping hazards for rig crews, damage to drilling equipment, and routine and tedious work performed almost daily,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

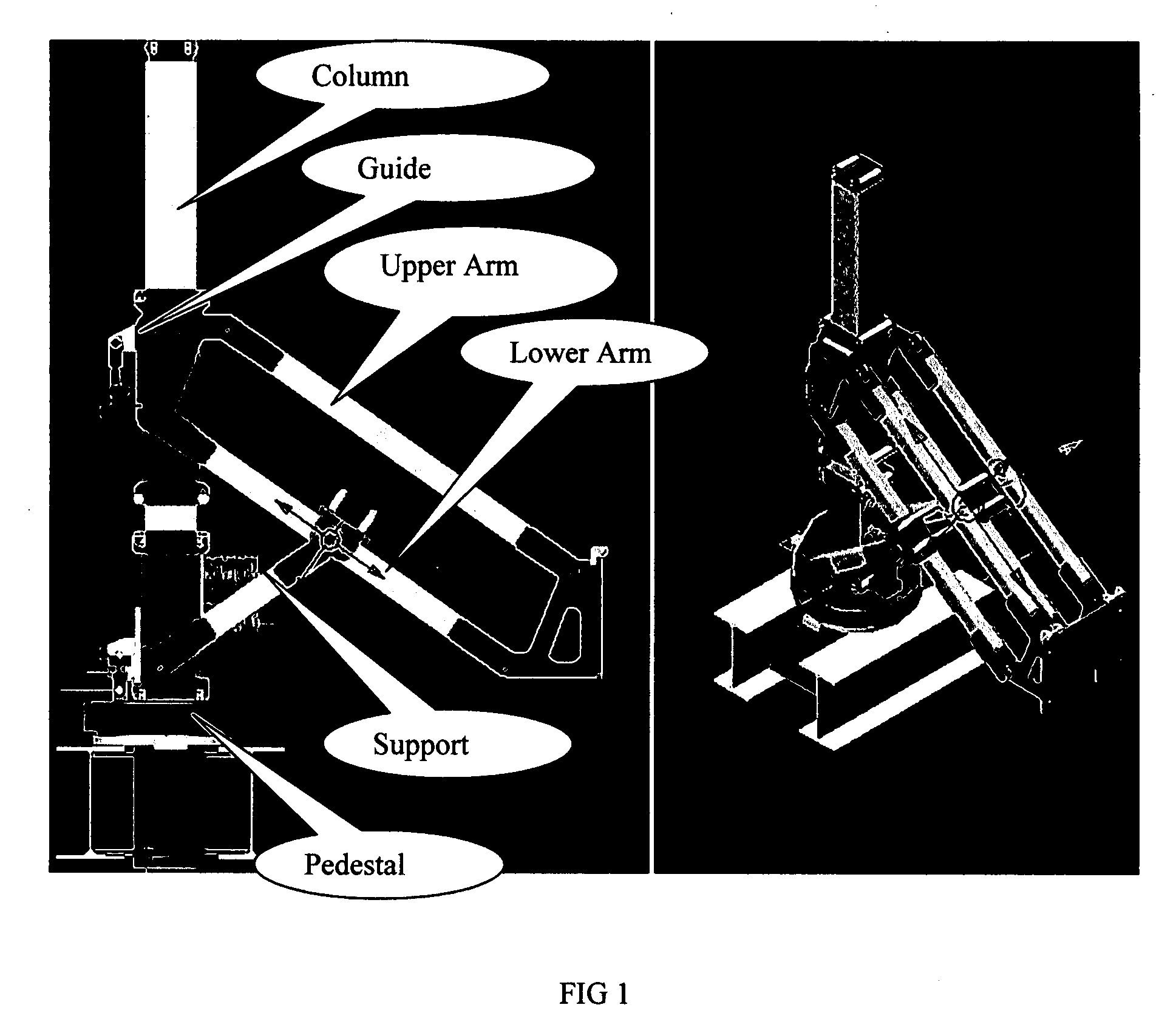

[0016]FIG. 1 is a 3d picture showing the preferred embodiment of the articulated arm assembly without showing a drilling apparatus attached the lower end of the parallelogram.

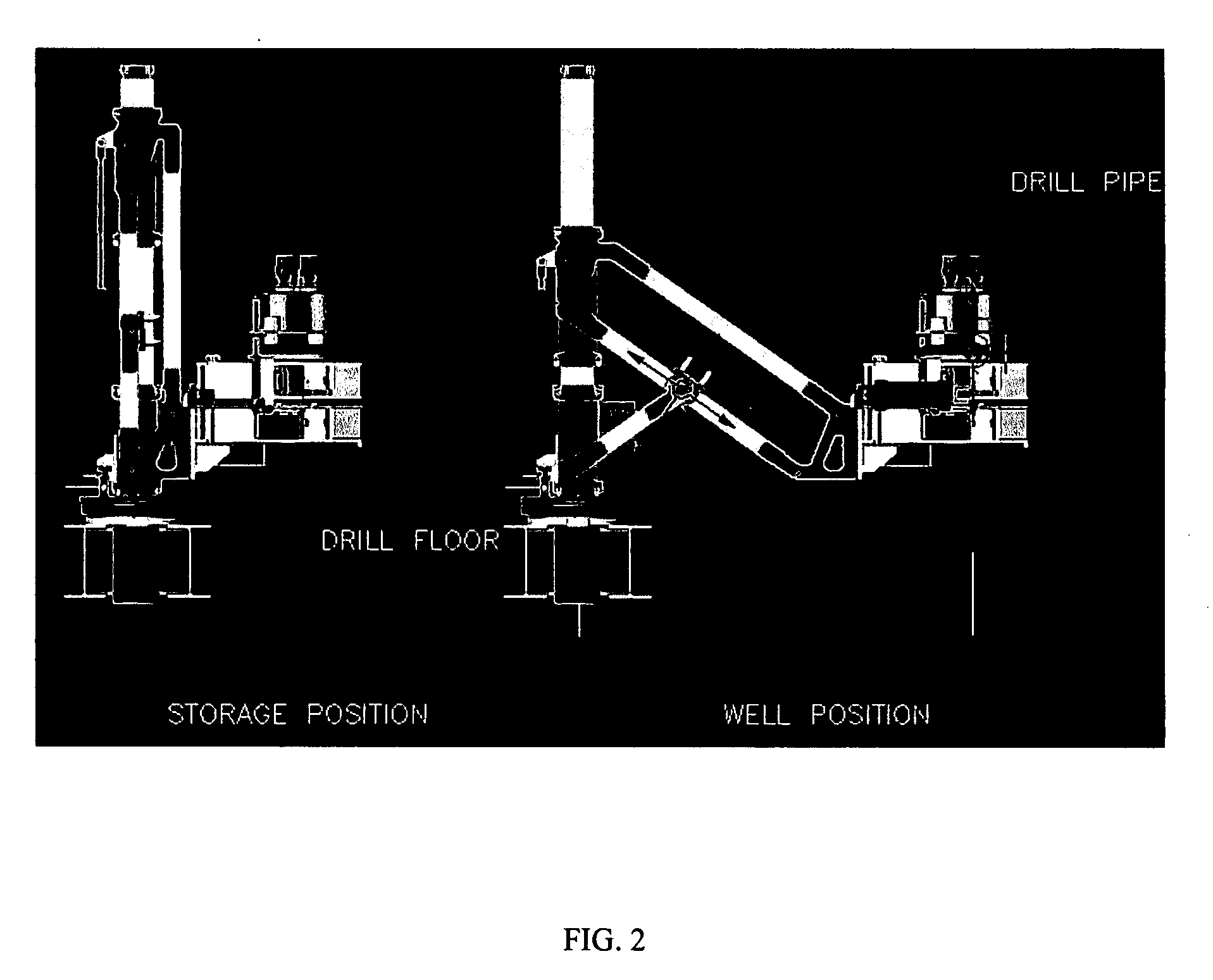

[0017]FIG. 2 is a typical arrangement of the articulated arm assembly with drilling apparatus such as a power tong attached to the lower end of the parallelogram. It shows the drilling apparatus is located in a storage position and travels to the well center by the articulated arm assembly.

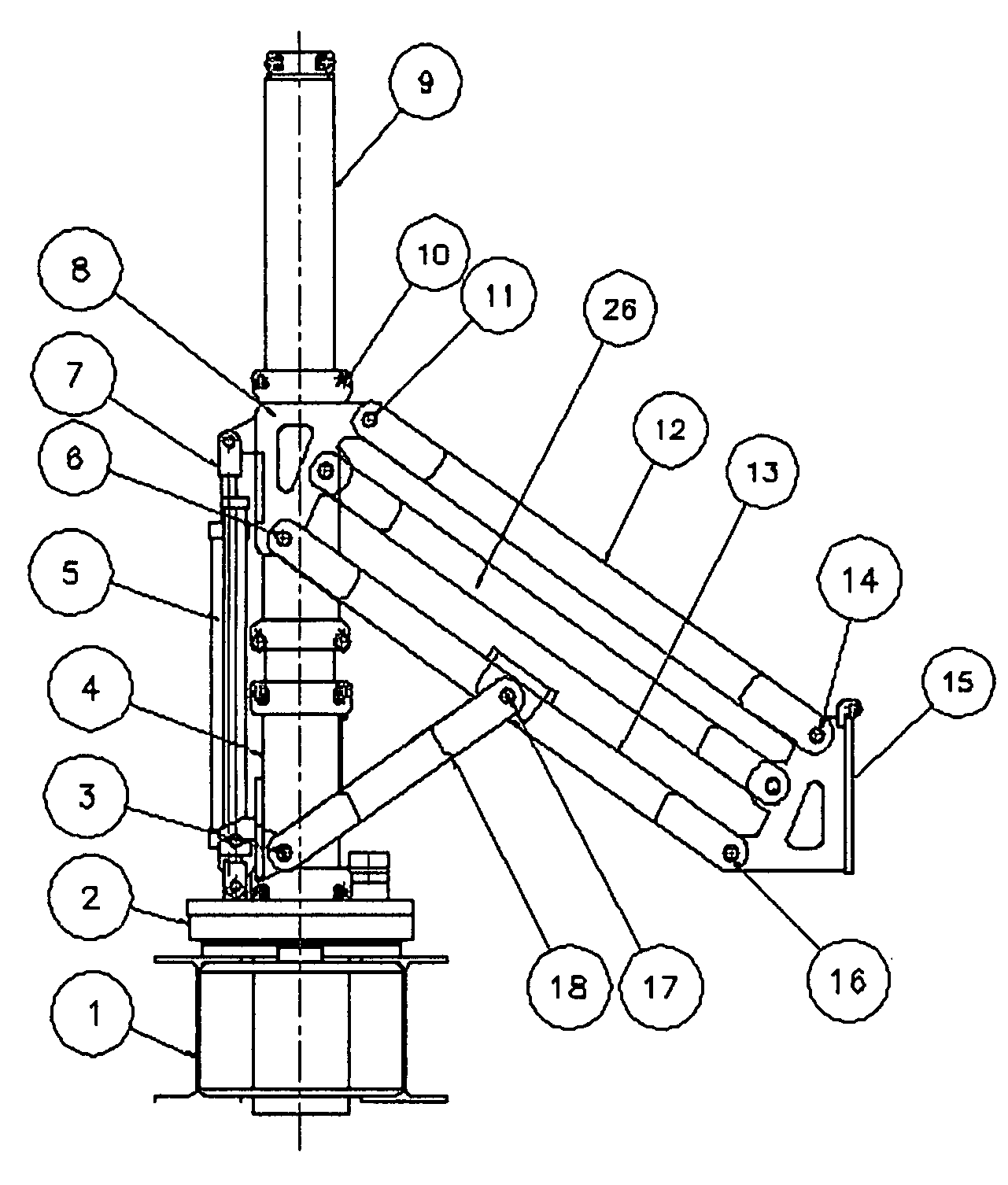

[0018]FIG. 3 is the configuration drawing of a preferred embodiment of this articulated arm assembly without showing a drilling apparatus or tool attached.

[0019]The arm assembly comprises at least one parallelogram which includes a upper member or linkage 12, lower member or linkage 13, a lower bracket 15, a upper linkage or the guide 8, wherein all the said members 12, 13 and the lower bracket 15 and the guide 8 are pivotally connected with pins.

[0020]The arm assembly further comprises a column 9, a pedestal 2 to support the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com