Golf club head

a golf club and head technology, applied in the field of golf clubs, can solve the problems of unsuitable face strength of magnesium alloy, and achieve the effect of strong bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

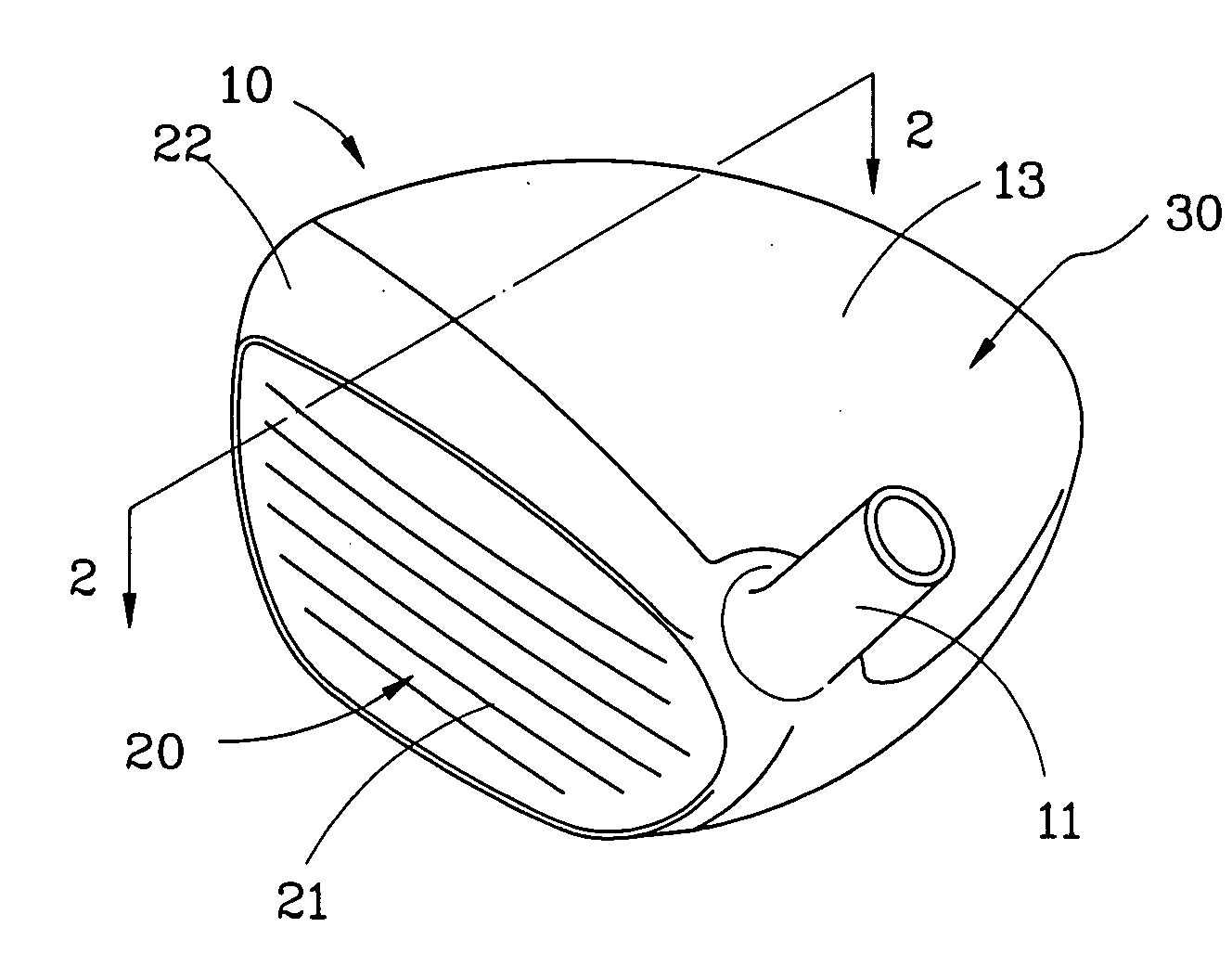

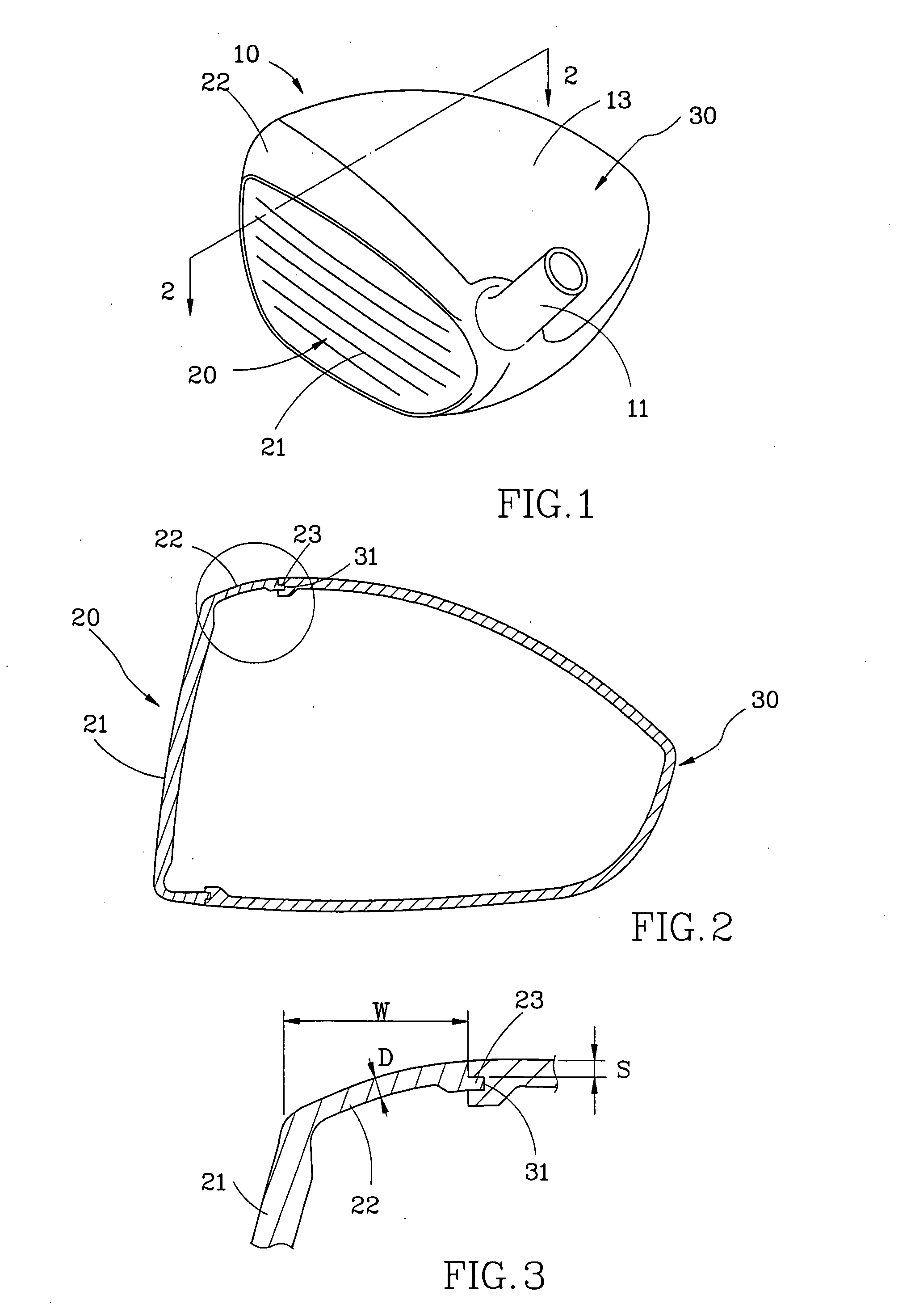

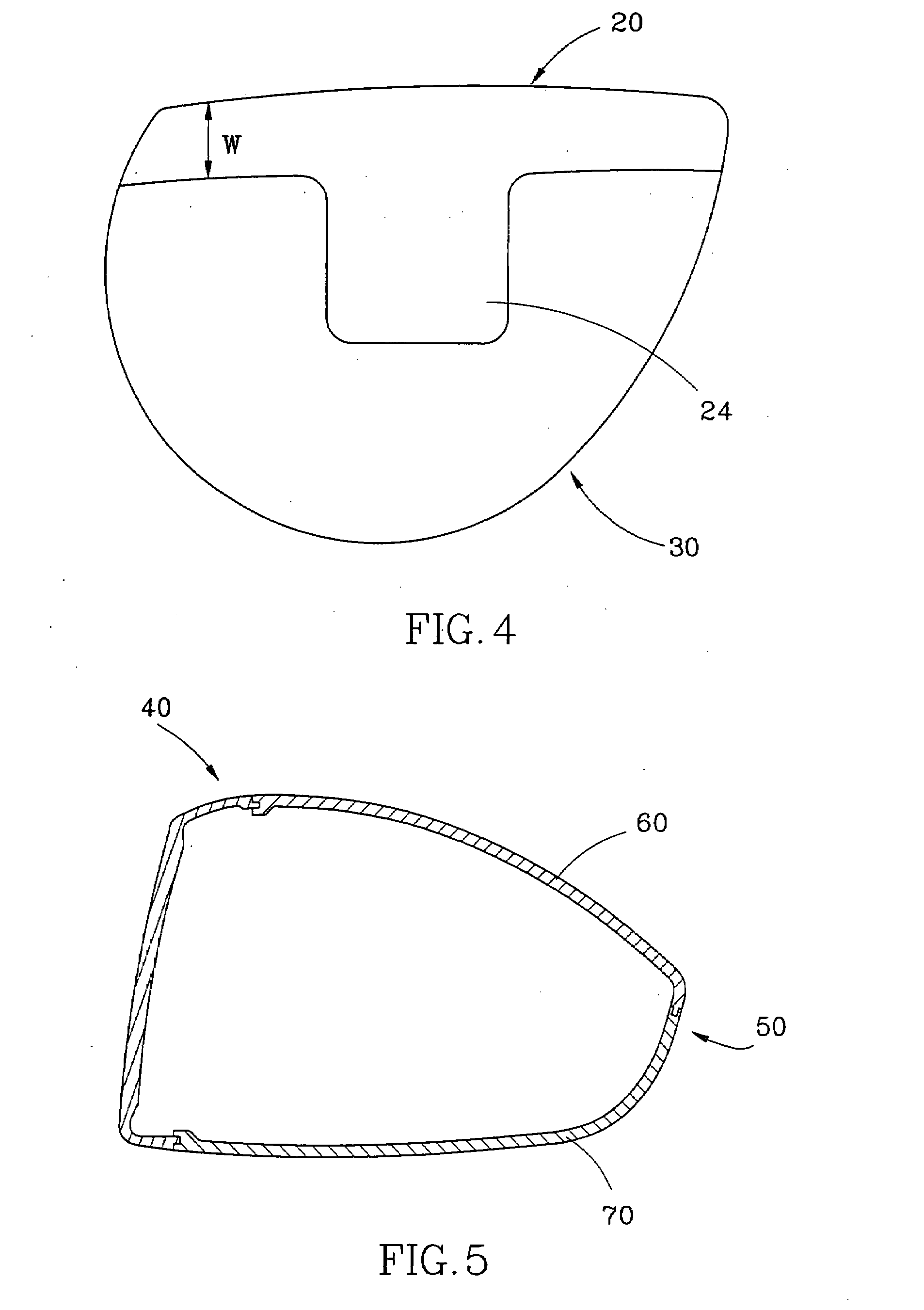

[0012]As shown in FIG. 1 to FIG. 4, a golf club head 10 of a first preferred embodiment of the present invention includes a front member 20 and a rear member 30.

[0013]The front member 20 is made of a flexible material, such as aluminum alloy, stainless or Maraging steel. The front member 20 has a face 21 and an annular wall 22 projected from a back of the face 21. The front member 20 is a cup-like member. The annular wall 22 has a connecting portion at a distal end. As shown in FIG. 3, a length W of the wall 22 is identical to or greater than 8 mm, and a thickness D thereof identical to or less than 2 mm. In the present embodiment, the length is 10 mm, and the thickness D is 1.5 mm.

[0014]The rear member 30 is made of a light material, such as magnesium alloy or aluminum alloy. The rear member 30 is a cup-like member also with a greater depth. The rear member 30 has a connecting portion 31 at an open end to be engaged with the connecting portion 23 of the front member 20. As shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com