End point detection method applying resonance phenomenon, end point detection apparatus, chemical mechanical polishing apparatus on which the detection apparatus is loaded, and semiconductor device fabricated by the chemical mechanical polishing apparatus

a technology of resonance phenomenon and detection method, which is applied in the direction of semiconductor/solid-state device testing/measurement, manufacturing tools, and lapping machines, etc., to achieve the effect of preventing excessive polishing or insufficient polishing amount, high accuracy and comparatively low pri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

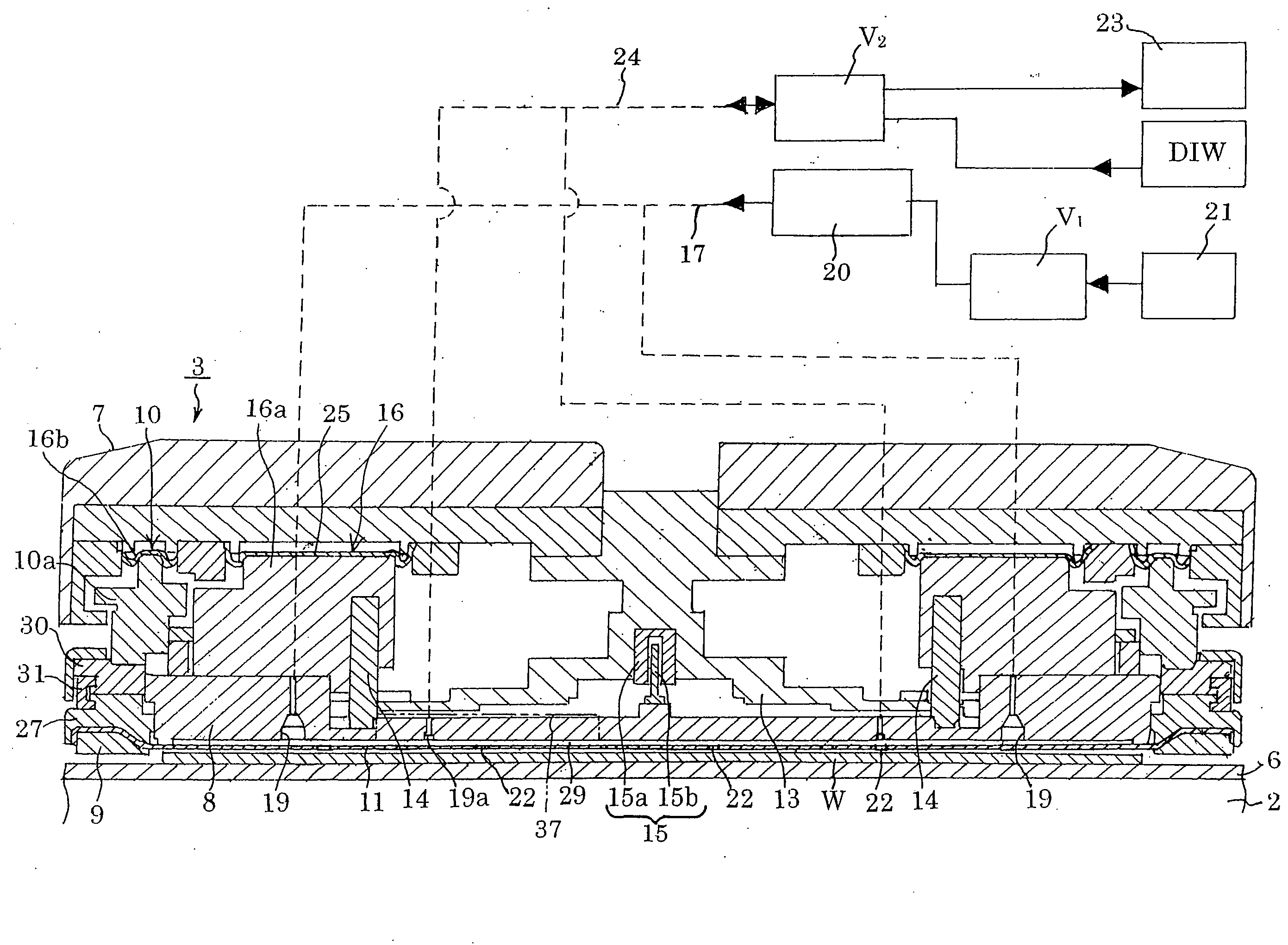

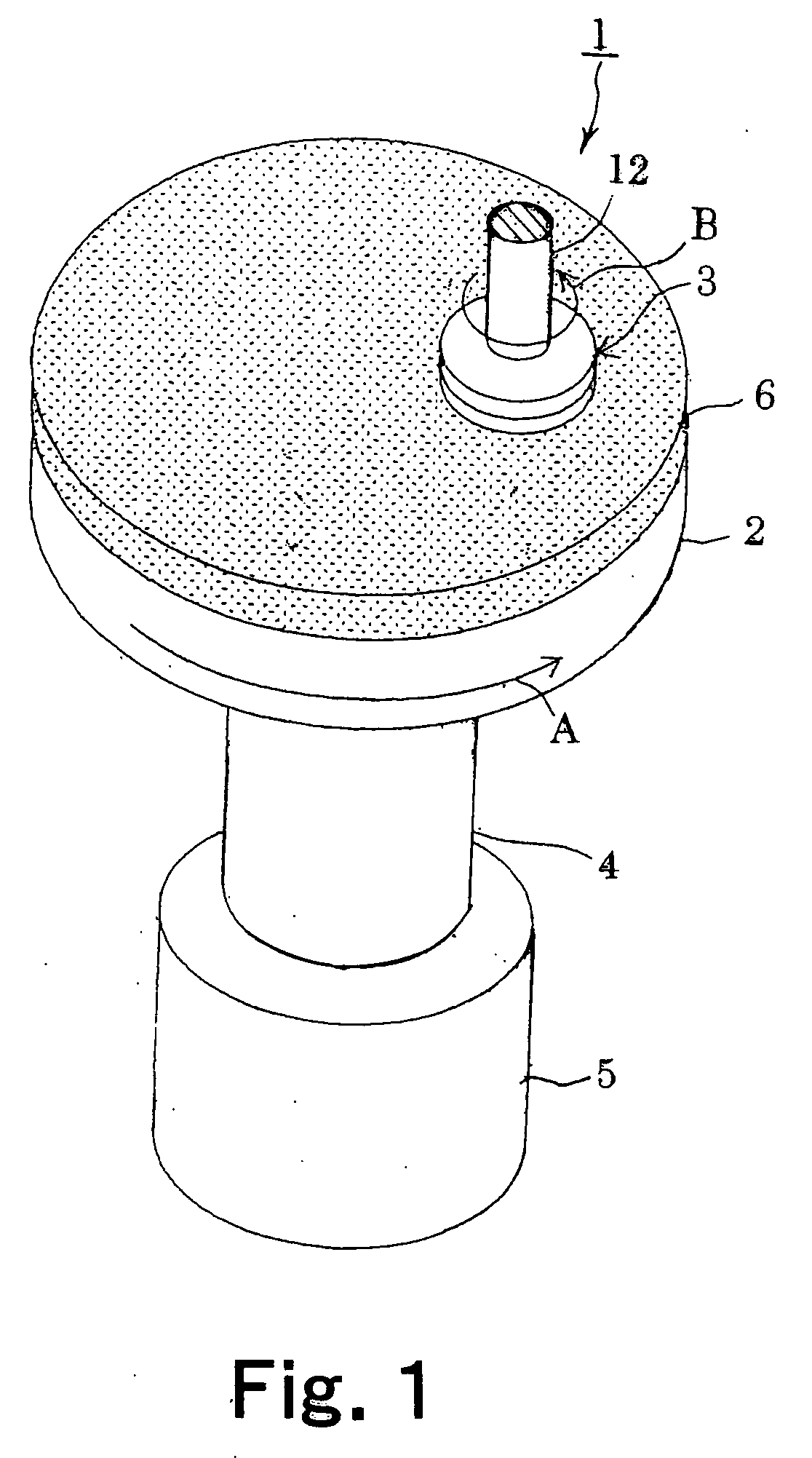

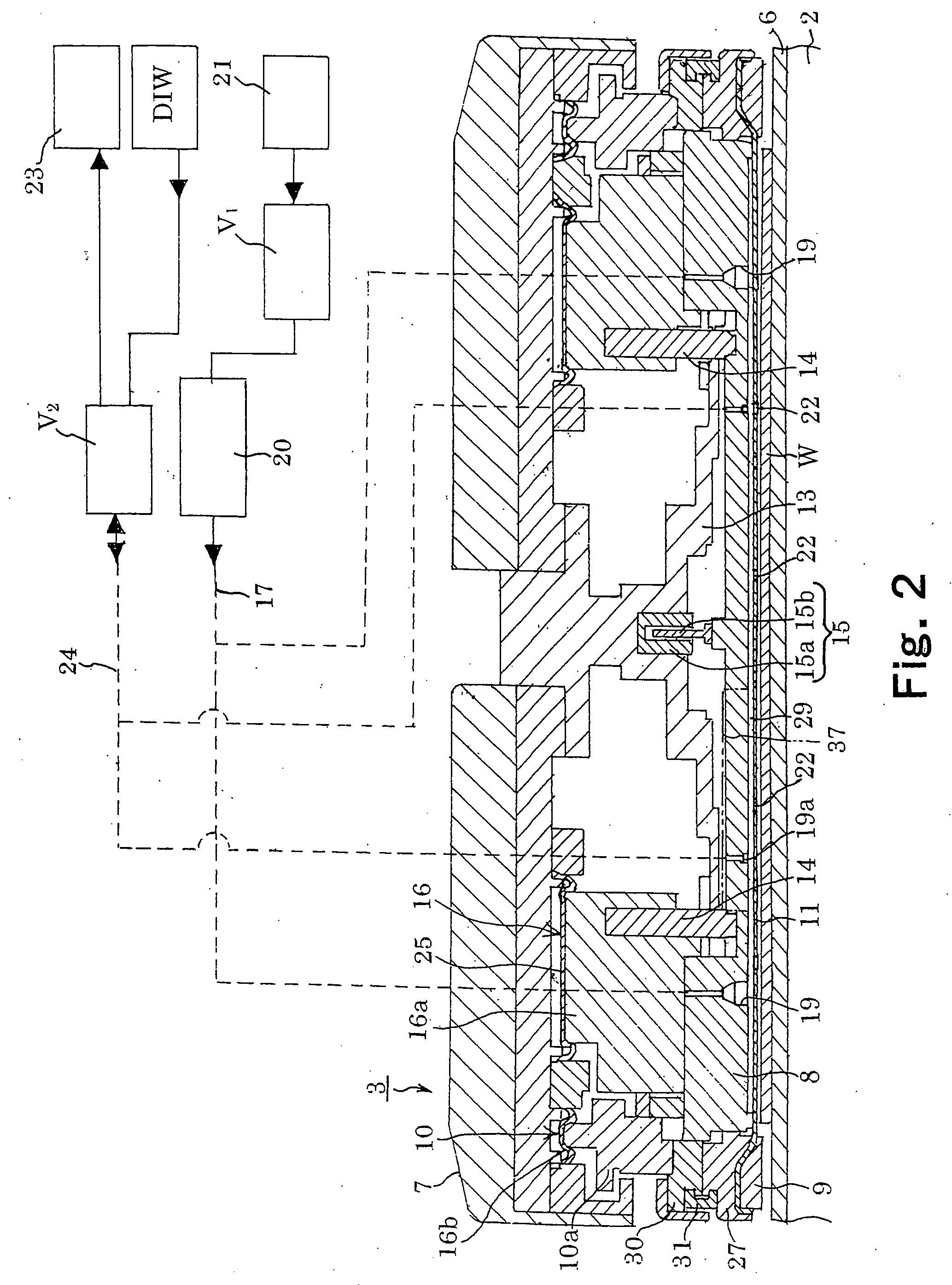

[0074]This is an end point detection method in which an electrically conductive film is polished and a polishing end point at which an appropriate thickness thereof is removed is detected in order to achieve objects of monitoring the variation in the thickness of the electrically conductive film in real time so as to reliably detect the polishing end point of the electrically conductive film at high accuracy, eliminating generation of noise, achieving low power consumption, and reducing the cost. The method is realized by using a sensor composed of an oscillation circuit of the Colpitts type or the like having a planar inductor and a concentrated constant capacitor, monitoring the variation in the thickness of the electrically conductive film in real time from the variation in the oscillation frequency of the sensor caused along with the variation in the thickness of the electrically conductive film opposed to the planar inductor, and detecting the polishing end point based on the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com