Substrate Polishing Method and Apparatus

a substrate and polishing technology, applied in the direction of grinding machine components, grinding machines, manufacturing tools, etc., can solve the problems of affecting the polishing effect of the substrate, affecting the polishing effect, so as to improve the correction accuracy, improve the processing pressure, and improve the polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

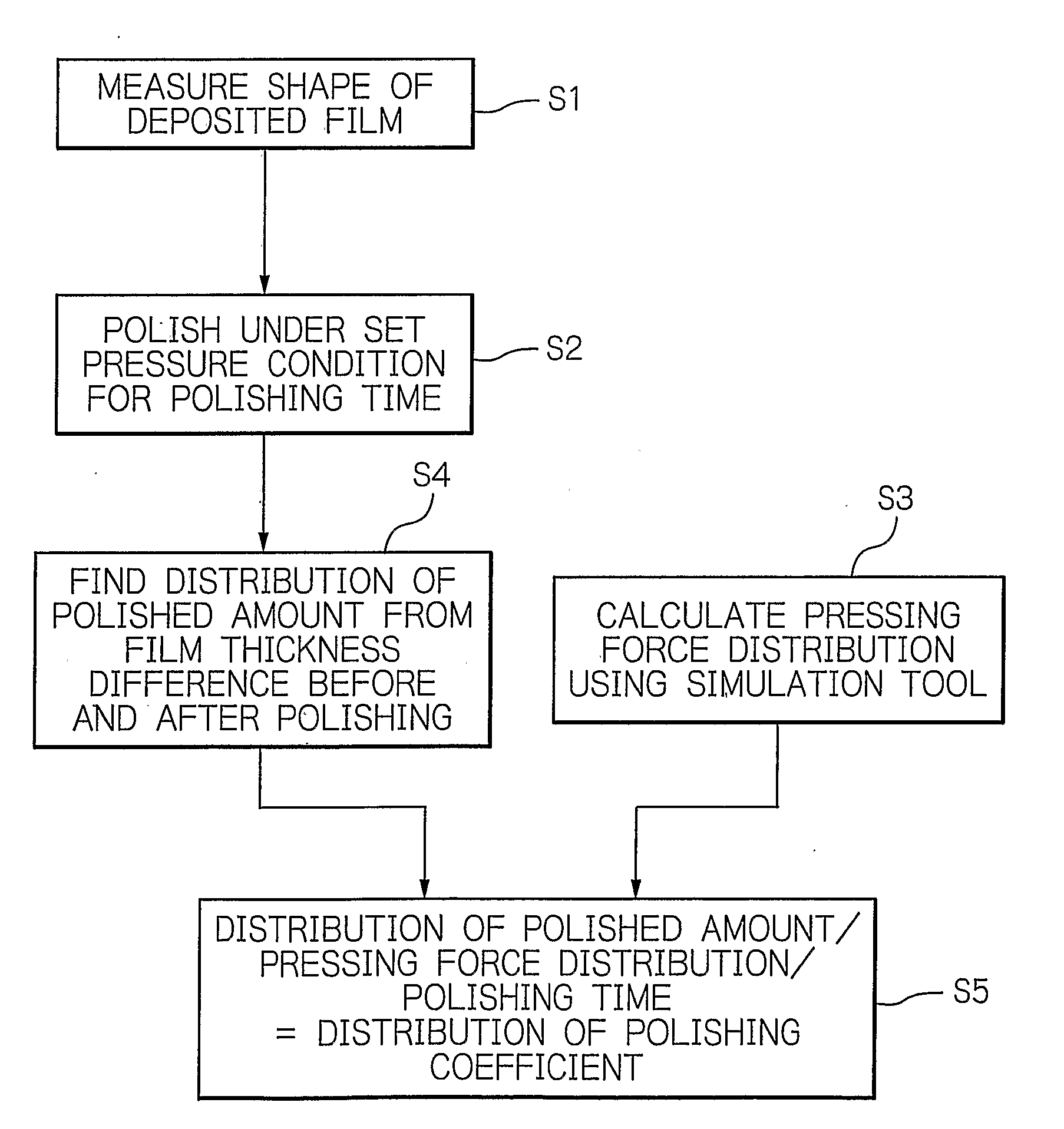

Method used

Image

Examples

Embodiment Construction

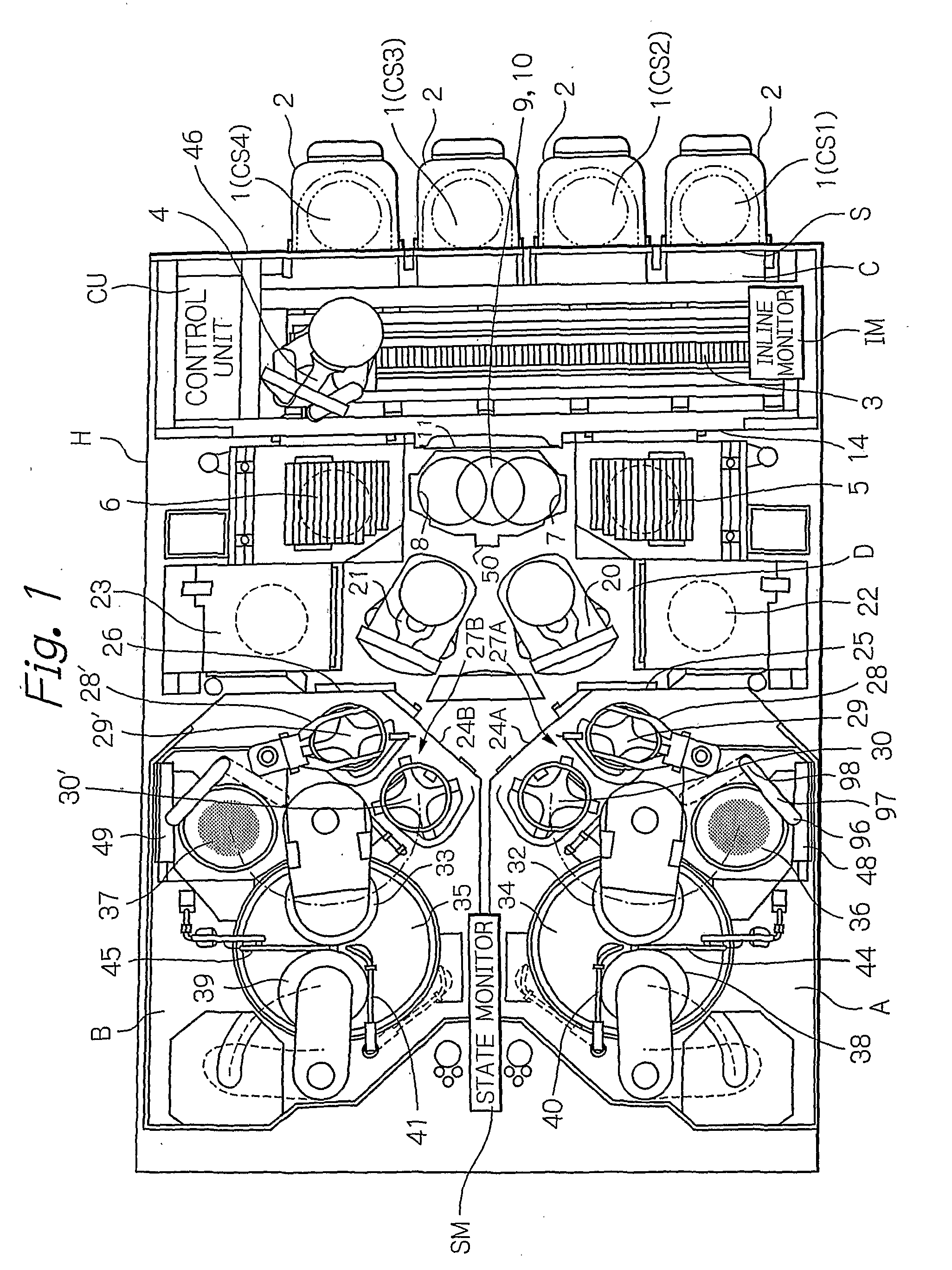

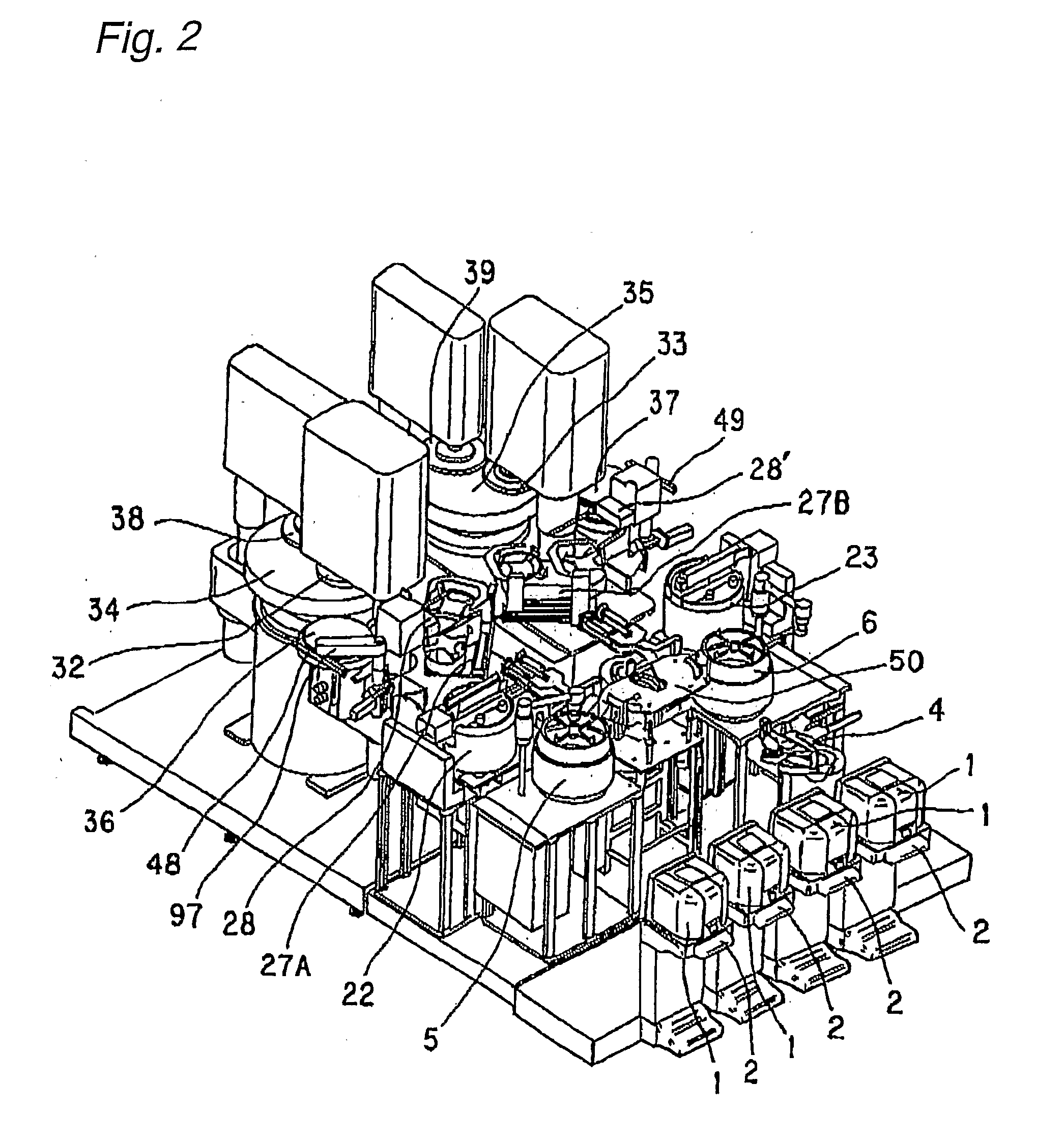

[0043]In the following, several embodiments of a polishing method and apparatus according to the present invention will be described in detail with reference to the accompanying drawings. First, one embodiment of the polishing apparatus according to the present invention will be described with reference to FIG. 1 which is a top plan view illustrating the layout and configuration of respective components in the polishing apparatus, and FIG. 2 which illustrates a perspective view of the polishing apparatus. In FIGS. 1 and 2, a transportation mechanism common to two polishing stations installed in areas A, B comprises separately installed linear transporters, each of which includes two linearly reciprocating stages that are transportation mechanisms dedicated to the two polishing stations, respectively. Specifically, the polishing apparatus illustrated in FIGS. 1 and 2 comprises four loading / unloading stages 2 for carrying wafer cassettes 1 which stock multiple wafers. A carrier robot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com