Smart magazine for a weapon simulator and method of use

a weapon simulator and smart magazine technology, applied in the field of smart magazine simulators, can solve the problems of reducing the realism of using the smart magazine, not providing a memory of the amount of ammunition, and not distinguishing the individual magazines of the simulated weapon,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

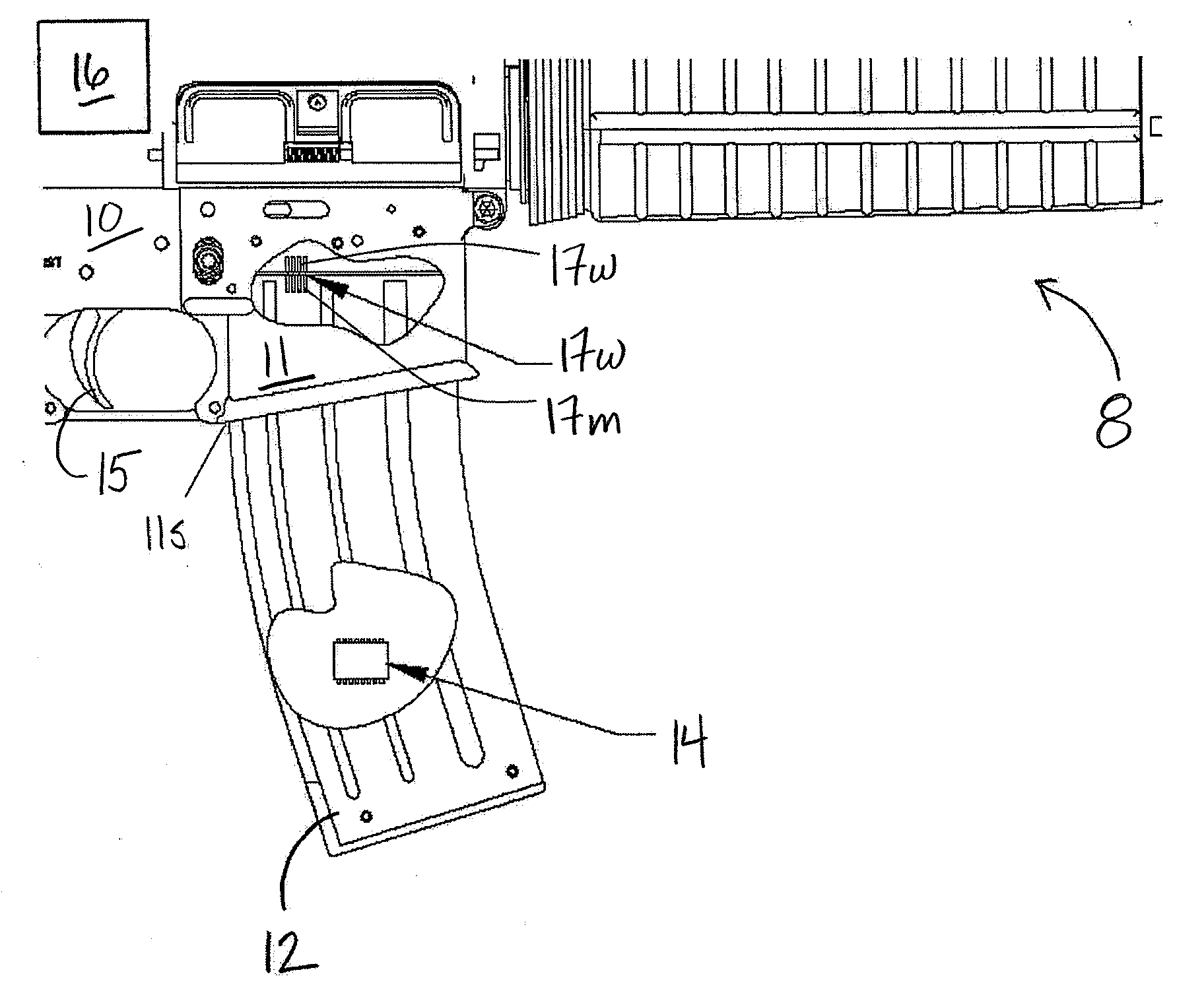

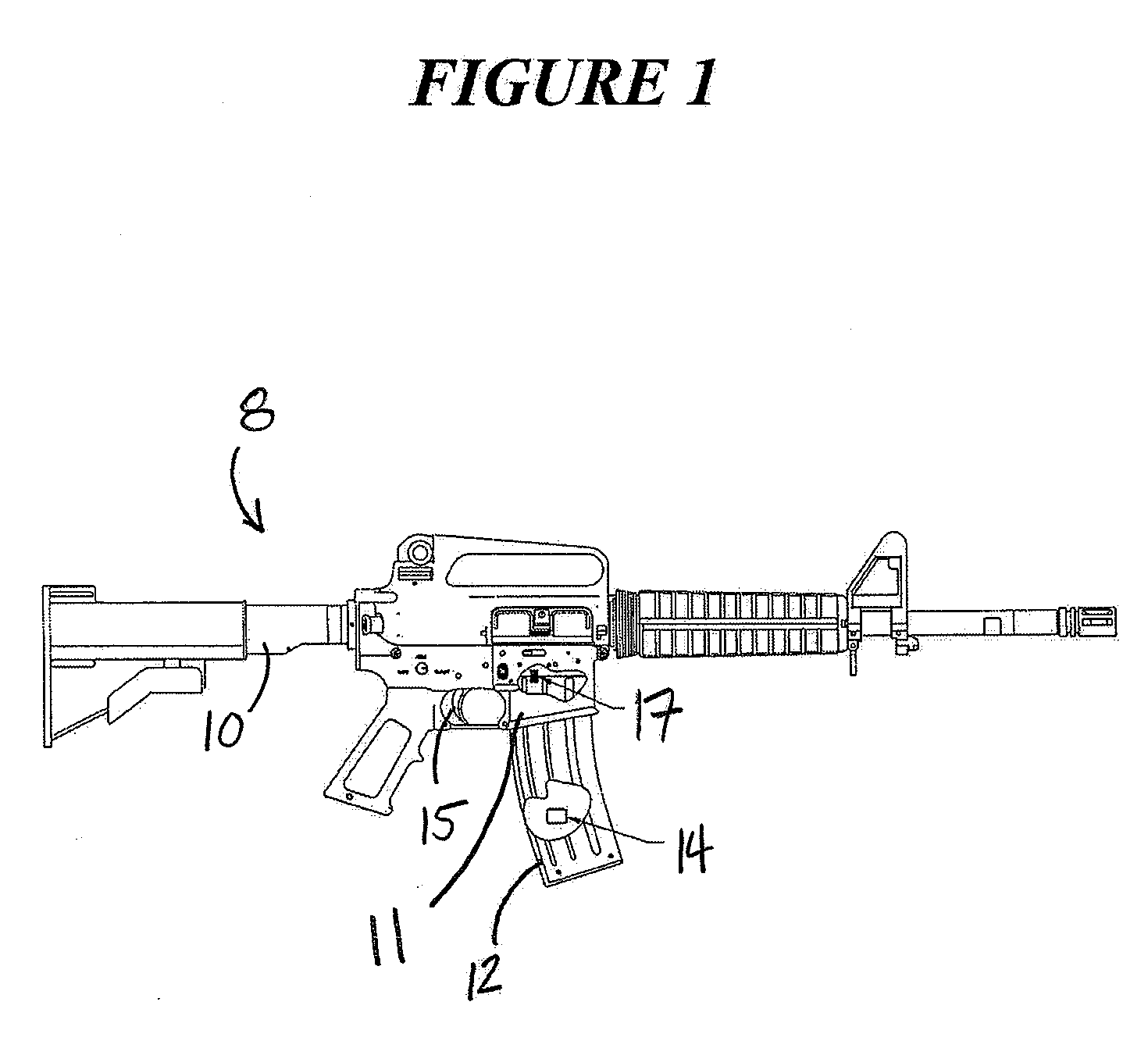

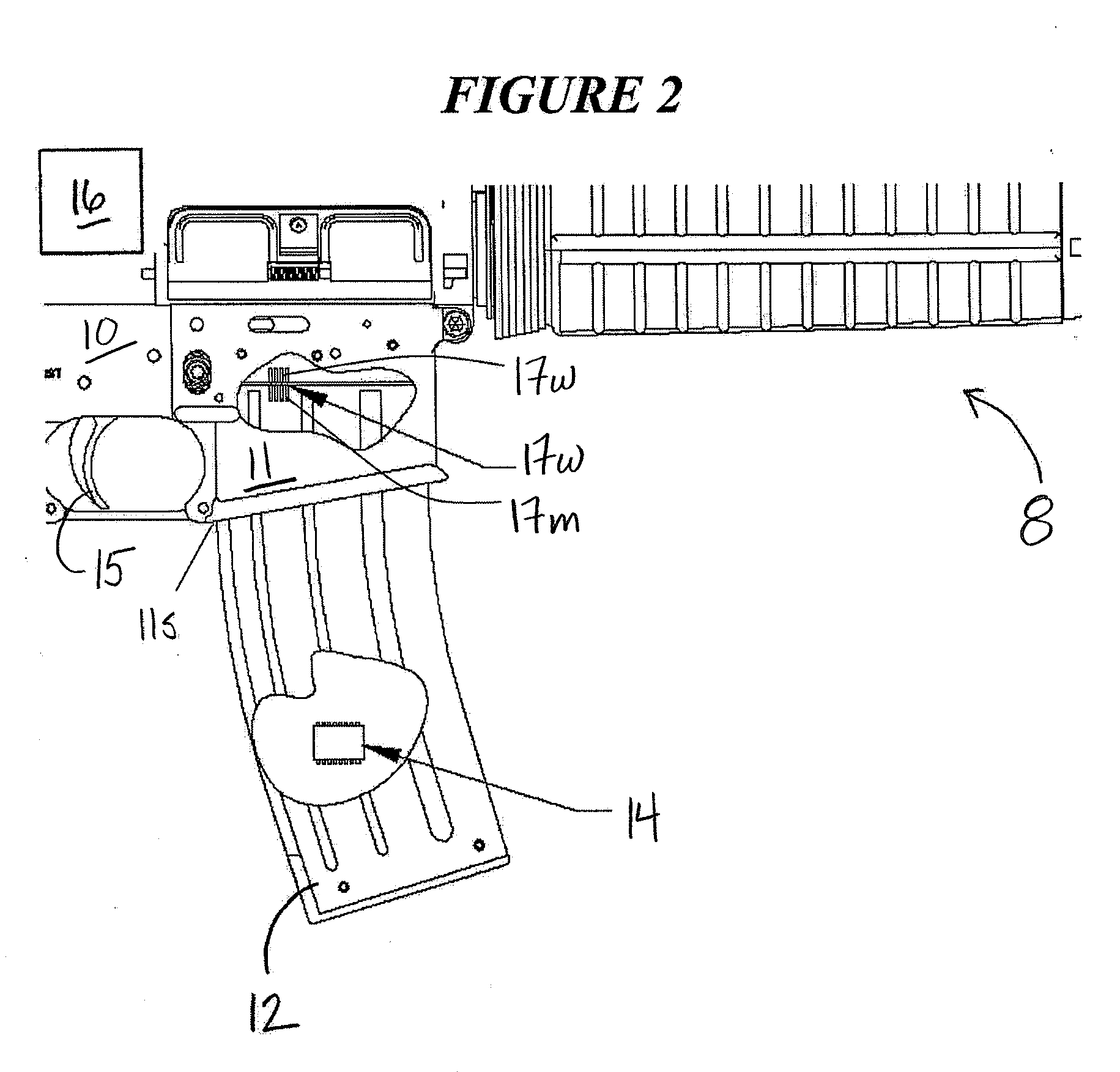

[0013]In the weapon simulator assembly 8 illustrated in FIGS. 1 through 3, the number of rounds of ammunition used in the simulated magazine 12 are tracked within the simulated magazine 12 itself. In particular, this weapon simulator assembly 8 includes the simulated weapon 10 having a receiver 11 and associated receiver slot 11 s to engage and secure the simulated magazine 12 with the simulated weapon 10. A magazine circuit 14 or similar processor is housed within the simulated magazine 12, and connected to at least one magazine electrical contact 17m in the simulated magazine 12. Similarly, the simulated weapon 10 includes a weapon processor 16 in communication with various switches and electronic equipment in the simulated weapon 10 to monitor and control operation of the simulated weapon 10. For example, among other connections, the weapon processor 16 is in communication with the trigger 15 to determine when the operator has attempted to fire the simulated weapon 10, as well as...

second embodiment

[0017]the weapon simulator assembly 8 is illustrated in FIGS. 4-7. In this embodiment, the weapon processor 16 of the simulated weapon 10 is able to differentiate between individual magazines 12 through the use of a unique identifier 20 or finger print associated with each magazine 12, and the weapon processor 16 will administer the operating parameters of the weapon simulator assembly 8 accordingly. Initially, the weapon processor 16 of the simulated weapon 10 will create a file associated with each magazine 12 and assign a predetermined value associated with the number calculate the number of rounds of ammunition provided for the associated magazine 12, and the processor 16 will keep track of the number of rounds of ammunition remaining in that particular magazine 12 according to the identifier of the particular magazine 12.

[0018]In particular, each magazine 12 includes an magnetic signature member or identifier 20, which could be a series of magnets 20 or voids positioned in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com