On-line calibration system for redundant temperature sensors

a technology of temperature sensor and calibration system, which is applied in the field of online calibration system for redundant temperature sensor, can solve the problems of less information being provided to plant operators, time and manpower required to perform cross calibration, and sensors considered out of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

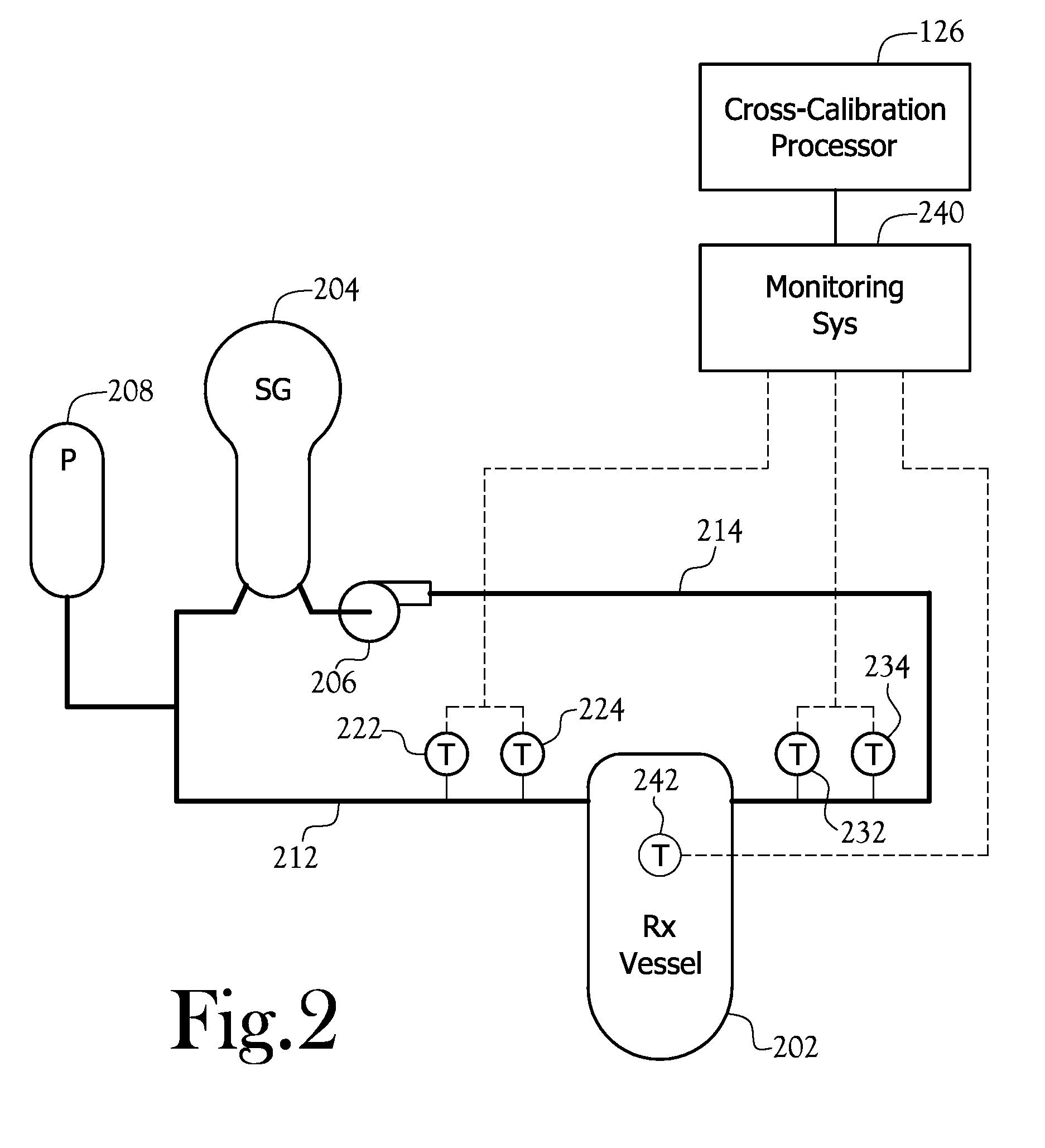

[0057] Methods and apparatus for an automated system for cross calibration are disclosed. The invention will be described as applied to a pressurized water reactor (PWR) for generating electric power. The invention, however, is applicable to other processes in which a multitude of sensors monitor a process.

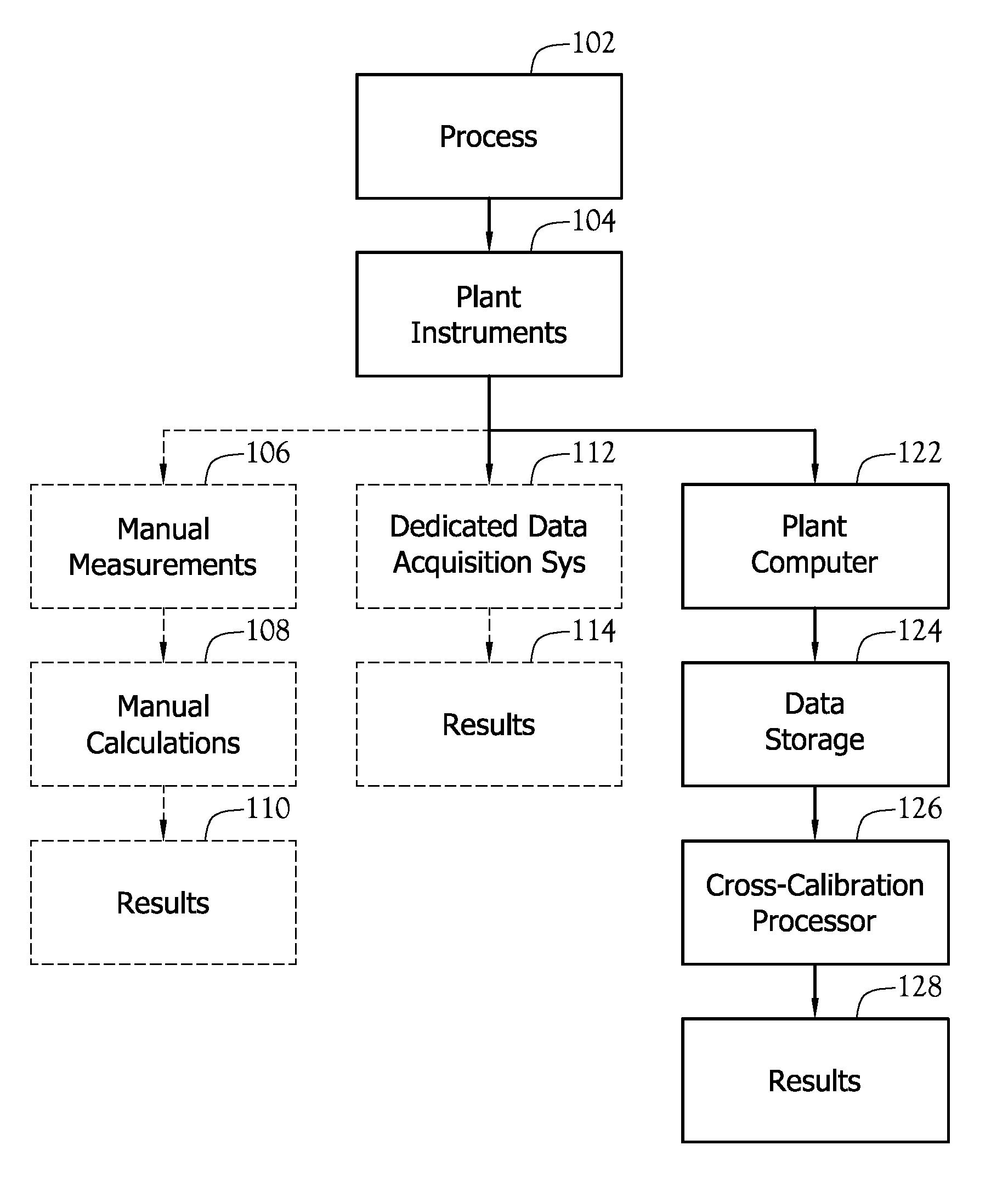

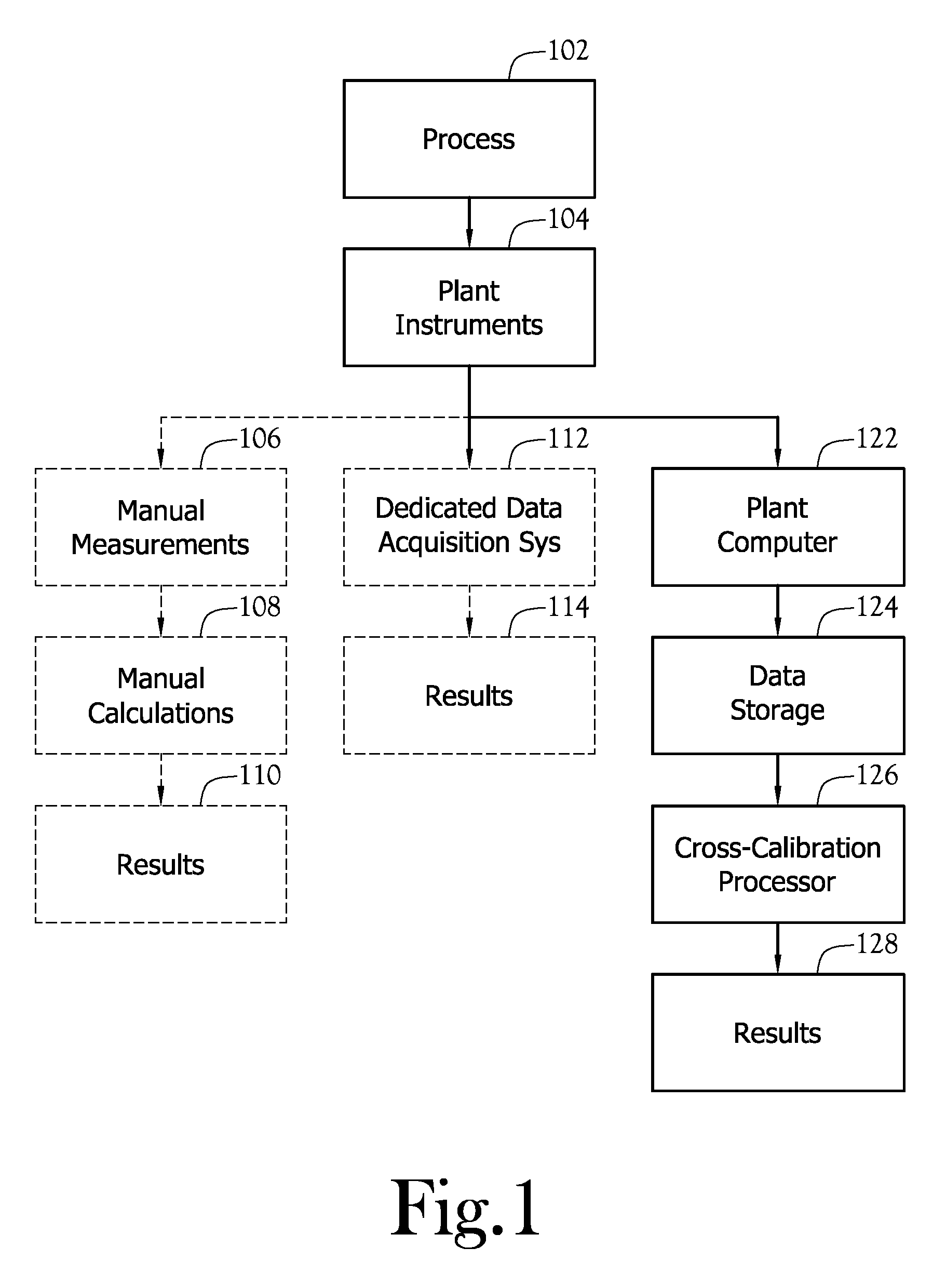

[0058]FIG. 1 illustrates a block diagram of both the prior art methods and the present invention. The plant process 102 is monitored by plant instruments 104, such as RTDs and CETs. As described above, cross calibration can be performed either by manually measuring 106 the instruments 104 and then performing manual calculations 108 to obtain the results 110 or by using a dedicated data acquisition system 112 to collect and analyze the data and produce the results 114.

[0059] In a typical plant environment, the plant instruments 104 provide data to a centralized plant computer 122 that monitors the instruments 104 and stores the instrument measurements in a data storage unit 124. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com