Singulation module/belt for separating sheet material

a sheet material and singulation module technology, applied in the direction of thin material handling, article separation, transportation and packaging, etc., can solve the problems of low tensile strength and shear strength, difficulty in controlling and/or anticipating the effectiveness of singulation of sheet material, and unique difficulties of sheet material used for postcard production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

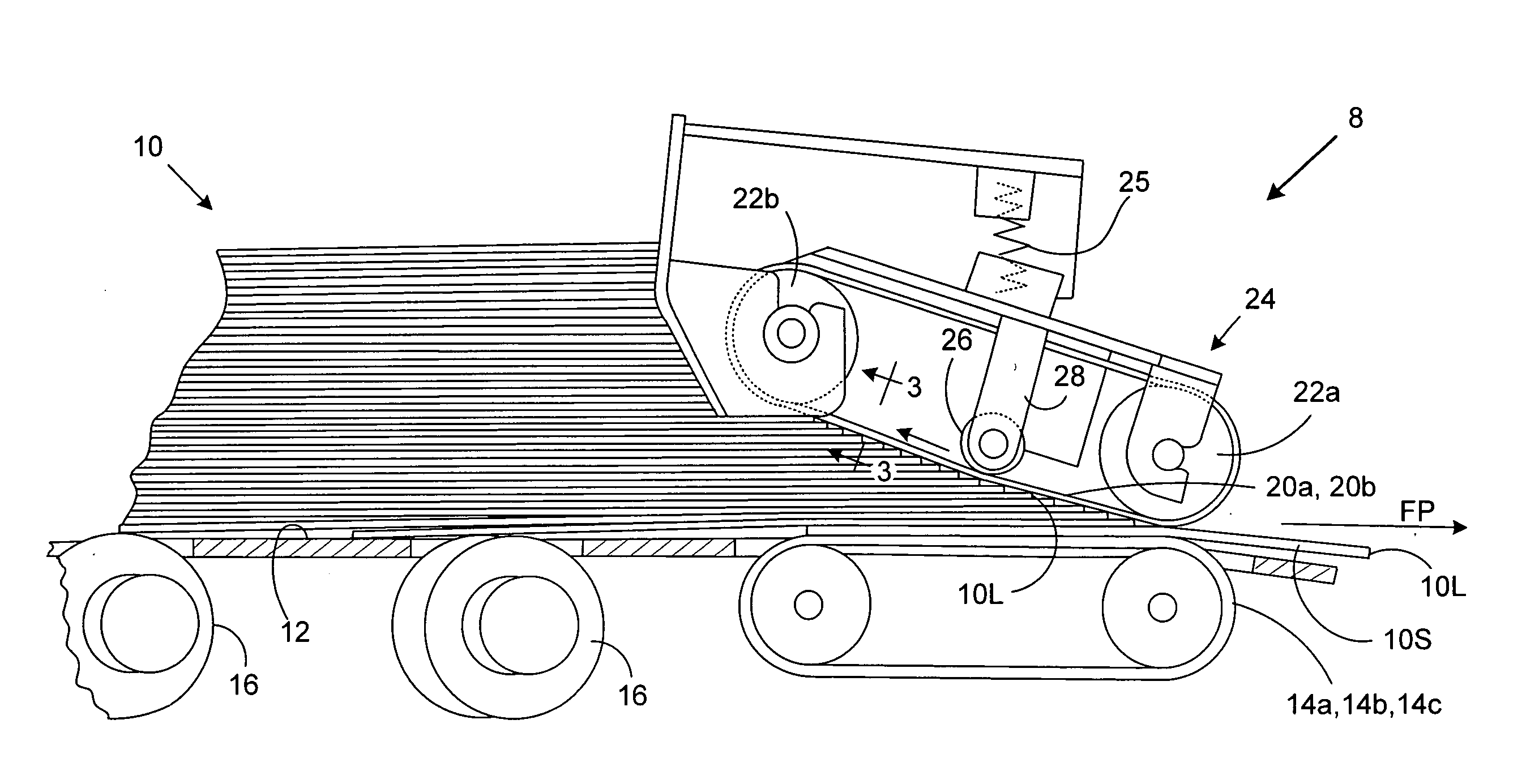

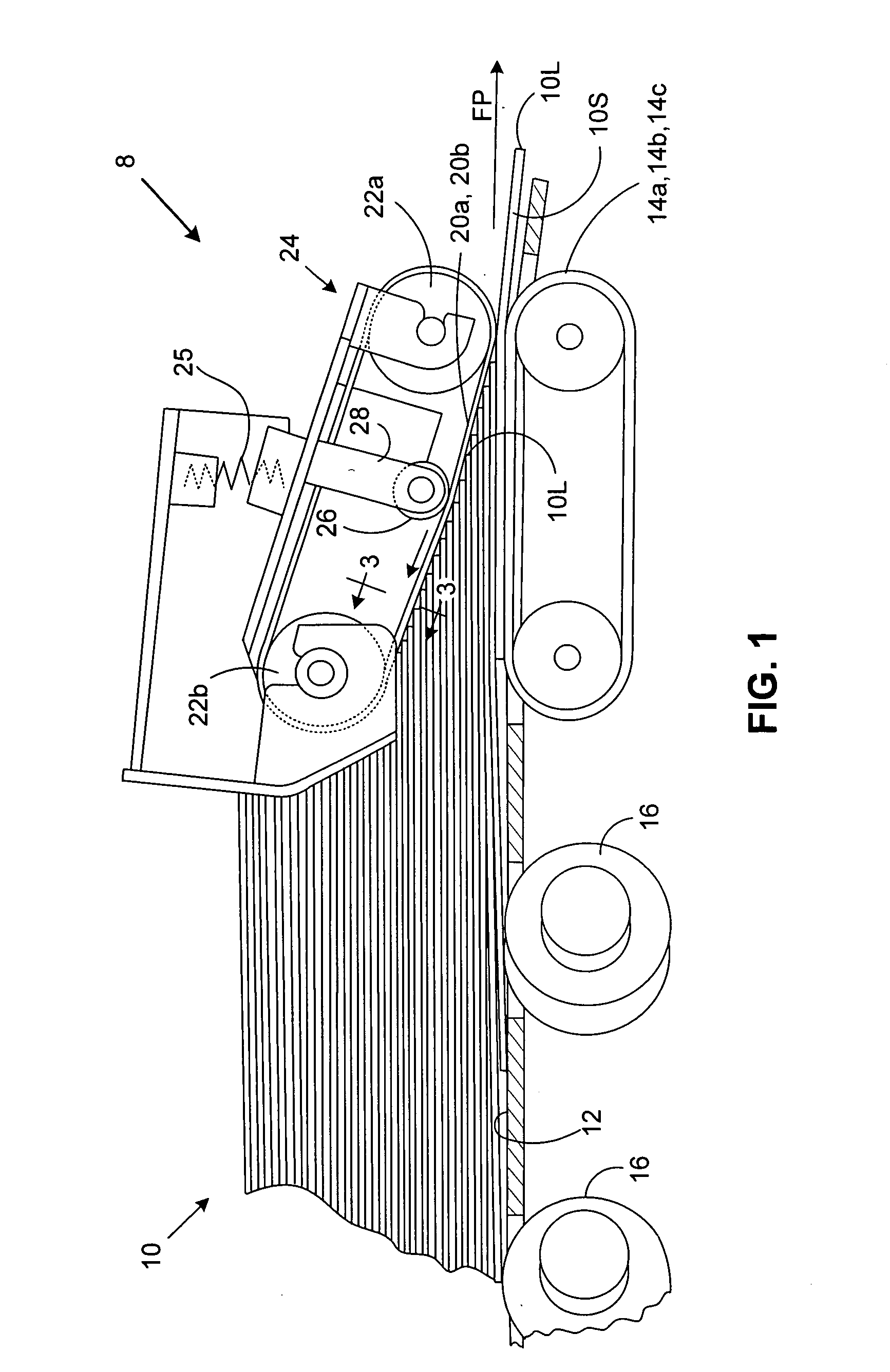

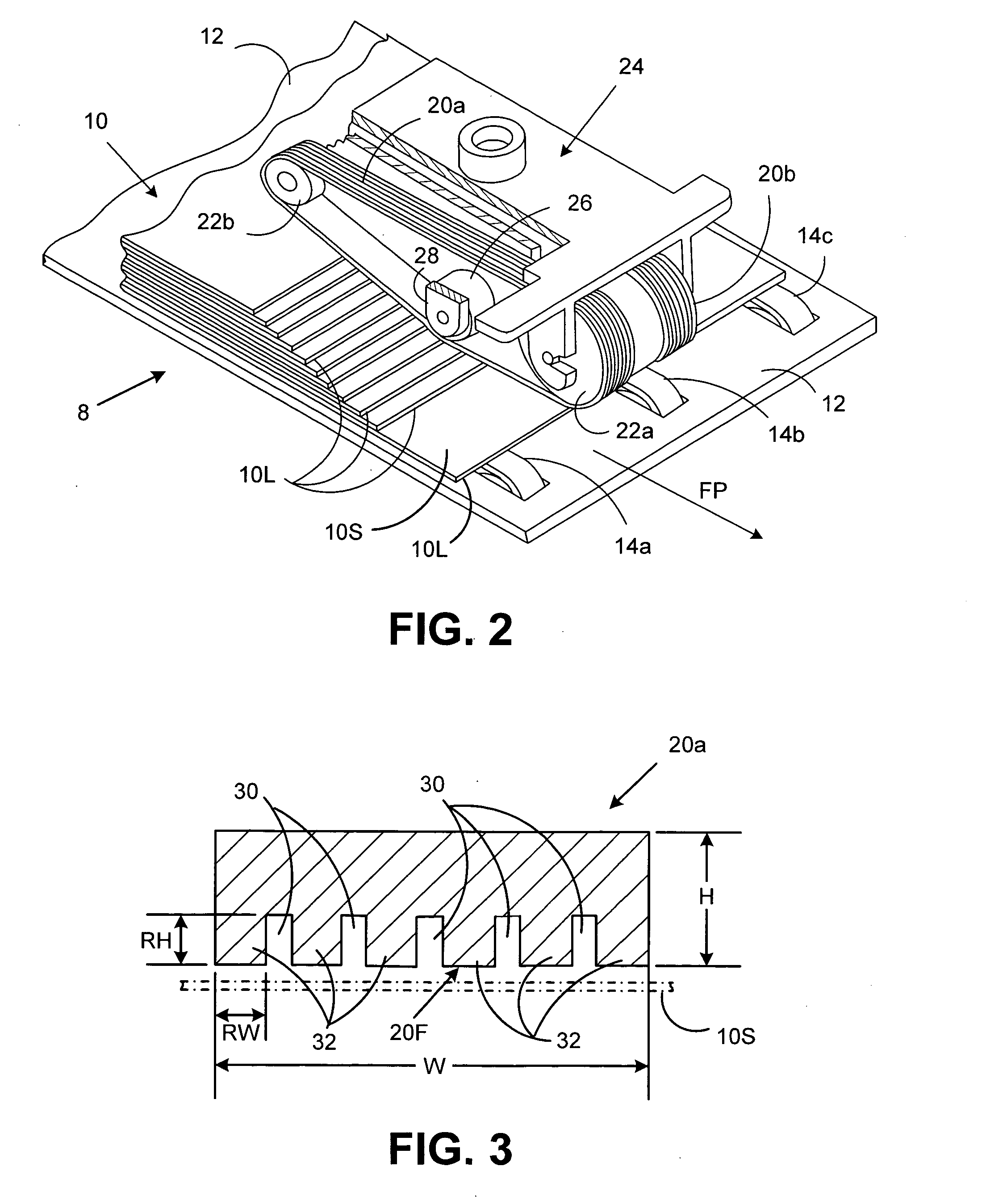

[0012]The present invention is described in the context of a singulation module for use in mailing machines, though the invention is applicable to any singulation module / belt for separating sheet material. Furthermore, while the invention is described in the context of singulation modules having belts moving in opposite directions, it will be appreciated that the belts need not traverse in opposite directions, but merely move relative to each other, e.g., one belt being stationary while another belt is driven to singulate the sheet material. Moreover, the singulation module is described as having an odd number of conveyor belts and even number of singulation belts disposed in a staggered array. While this configuration is most commonly employed, it should be appreciated that the singulation module may comprise any number or combination of belts, whether the module contains the same number of opposed belts or a multiple array of staggered belts.

[0013]In the broadest sense of the inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com