Method of mounting optical component and optical pickup

a technology of optical components and mounting methods, applied in the direction of mountings, optical head manufacture, instruments, etc., can solve the problems of difficult positioning and adjustment of the substrate, easy offset of the position and angle of the substrate, and difficulty in moving the substrate around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

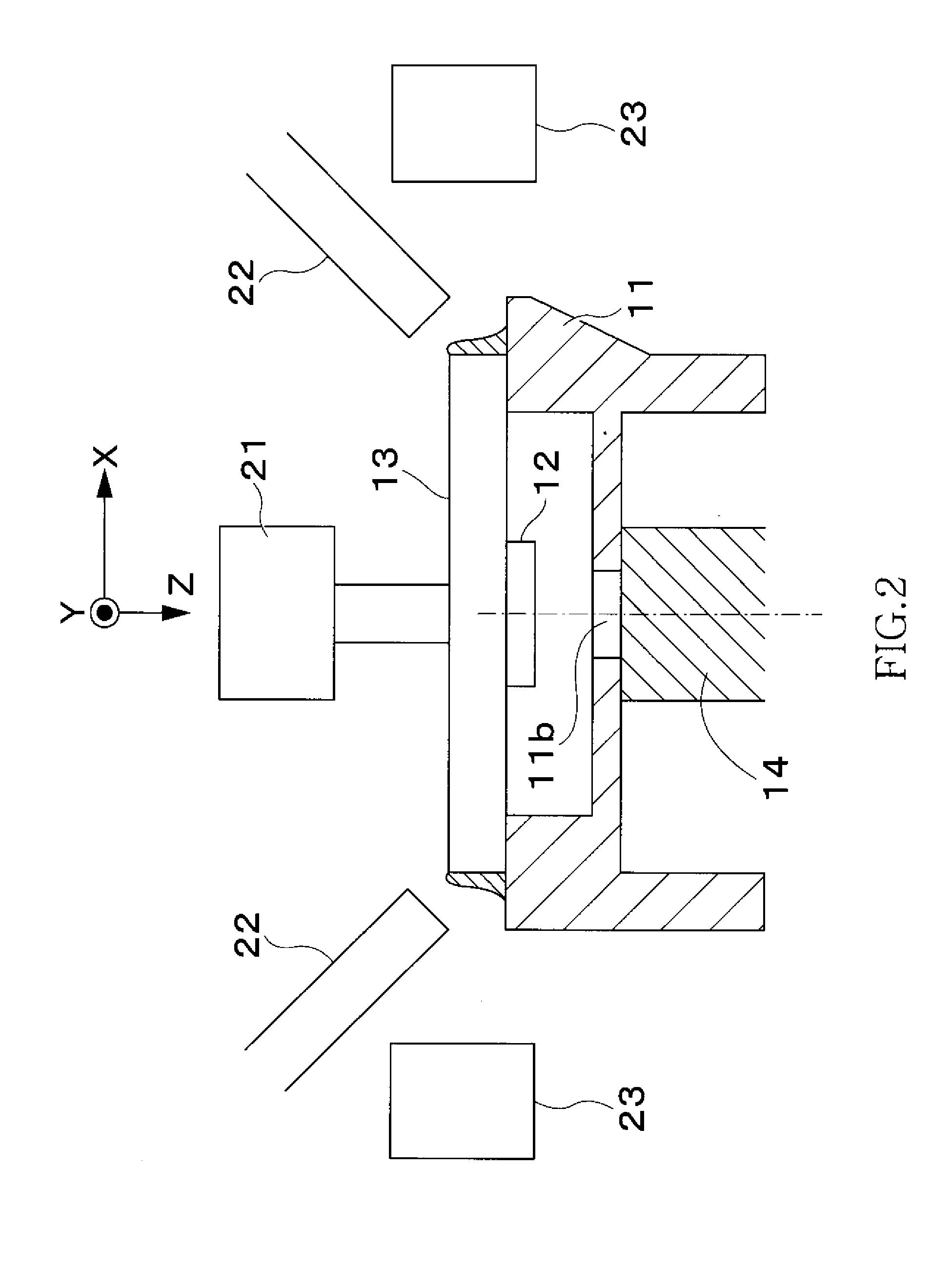

[0025]Preferred embodiments of the present invention will be described in detail hereinafter with reference to the accompanying drawings. In the present embodiment, a substrate on which a photoelement (PDIC) is mounted is used as an example of an optical component, and a method of mounting the substrate on the housing of an optical pickup will be described.

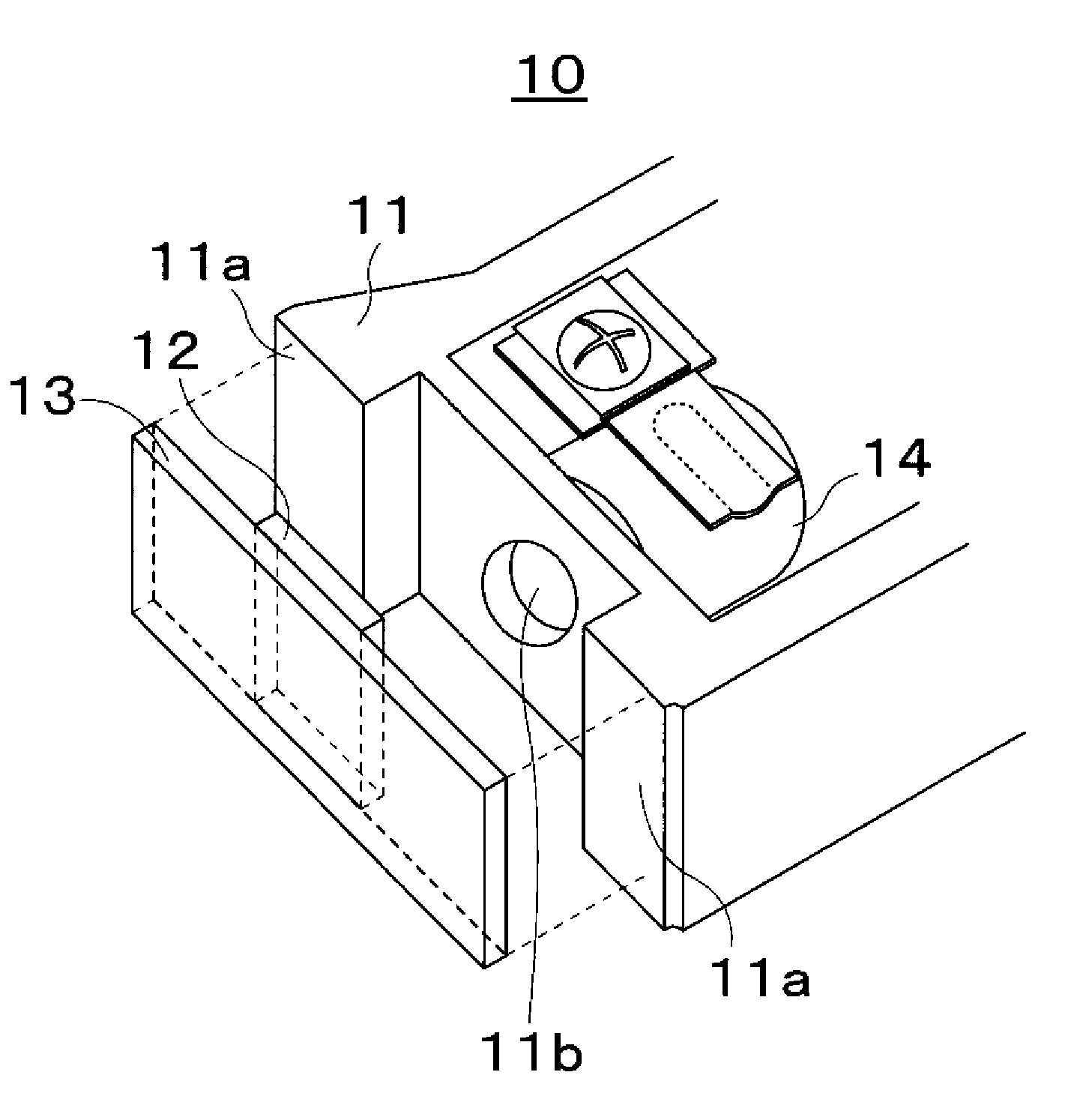

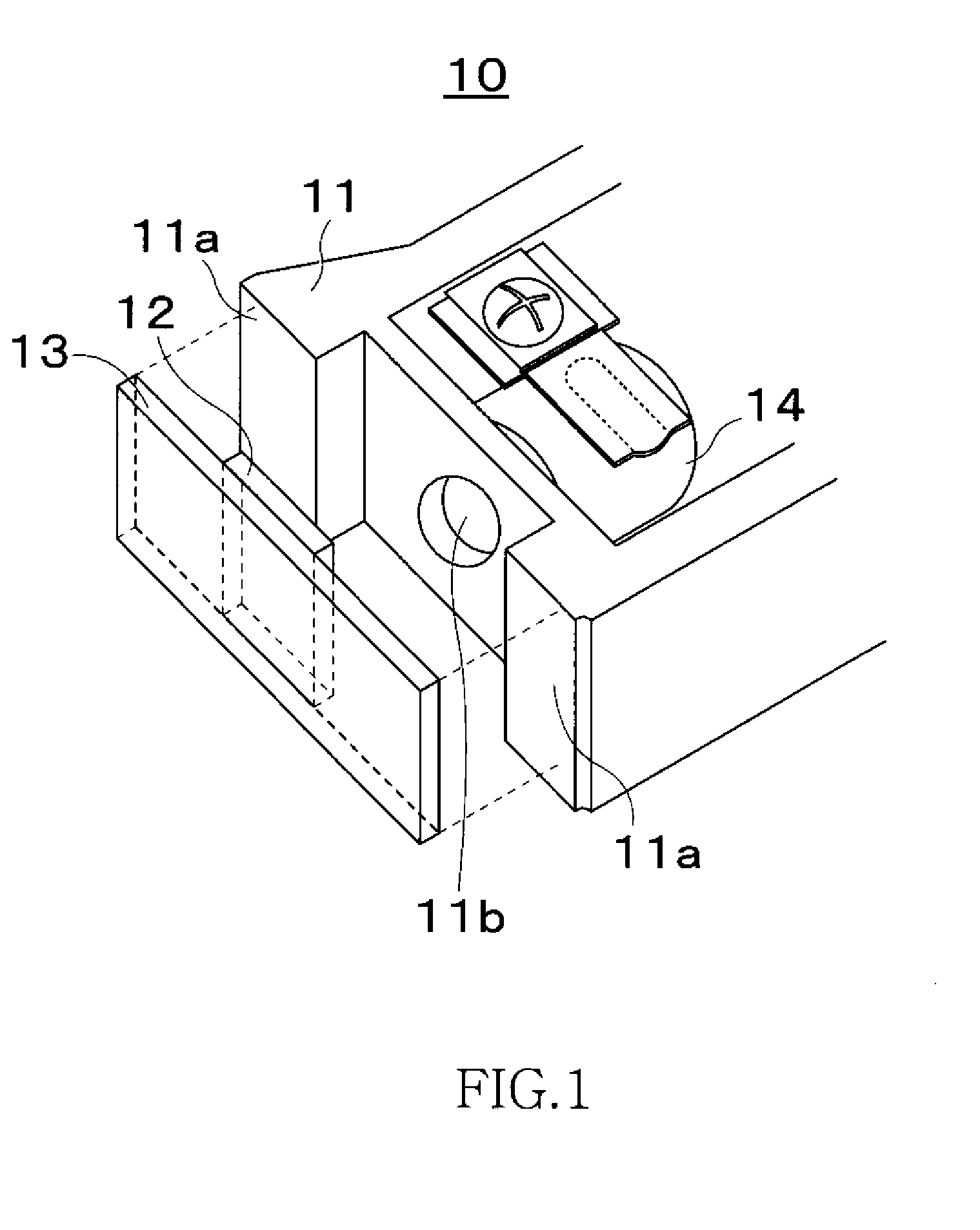

[0026]FIG. 1 is a schematic exploded perspective view that partially shows the configuration of an optical pickup.

[0027]As shown in FIG. 1, an optical pickup 10 comprises a housing 11 in which a light source, lens, and other components of an optical system are mounted. A mounting surface 11a for mounting a substrate 13 on which a photoelement 12 is mounted is formed on the side surface of the exterior of the housing 11. The two ends of the substrate 13 are mounted on the mounting surface 11a, whereby the photoelement 12 is mounted on the housing 11. In this case, the photoelement 12 is disposed on the optical axis of the optical s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com