Electromagnetic clutch and compressor fitted with the electromagnetic clutch

An electromagnetic clutch and armature technology, applied in the direction of magnetic drive clutches, clutches, non-mechanical drive clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Detailed description of the preferred embodiment

[0054] The first embodiment of the present invention will be described below with reference to the accompanying drawings. However, the present invention is not limited to these examples.

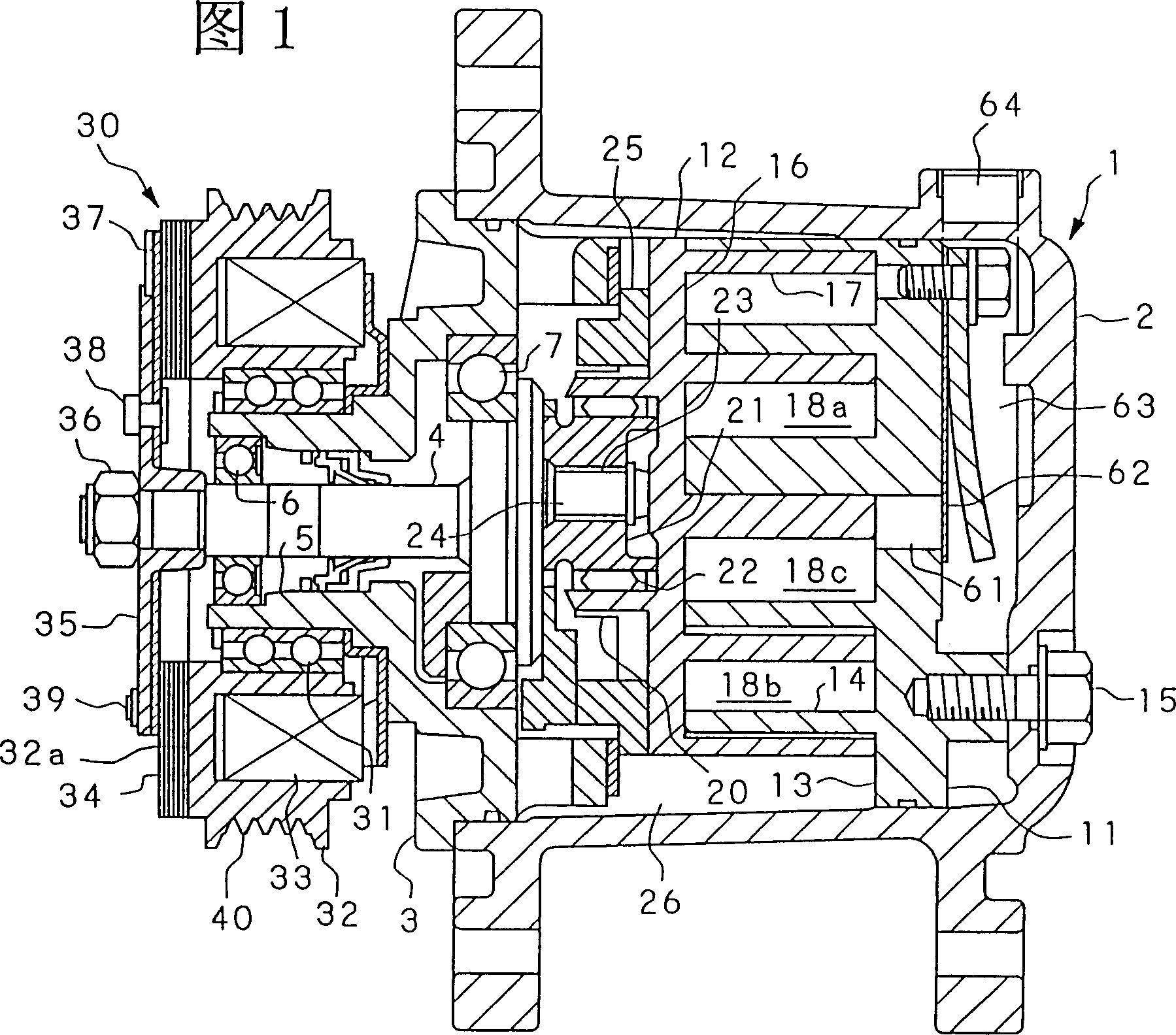

[0055] Fig. 1 is a longitudinal sectional view of a compressor of the present invention.

[0056] In the compressor shown in FIG. 1, a housing 1 is composed of a cup-shaped main body 2 and a front housing 3 fixed by bolts not shown in the figure.

[0057] The scroll compressor components are composed of a fixed scroll 11 and an orbiting scroll 12 , and are disposed inside a cup-shaped main body 2 .

[0058] The fixed scroll 11 is provided with an end plate 13 and a spiral wrap 14 protruding from an inner surface of the end plate 13 . The end plate 13 is fixed on the cup-shaped main body 2 by bolts 15 . The orbiting scroll 12 is provided with an end plate 16 and a spiral wrap 17 protruding from an inner surface of the end plate 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com