Poly-phasic multi-coil generator

a generator and polyphasic technology, applied in the field of generators, can solve the problems of reducing the efficiency of the generator, narrowing the “efficient” operational range, and the system not creating an efficient generator, so as to reduce the negative impact of system faults, reduce system damage, and reduce the effect of system damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The following description is demonstrative in nature and is not intended to limit the scope of the invention or its application of uses.

[0093] There are a number of significant design features and improvements incorporated within the invention.

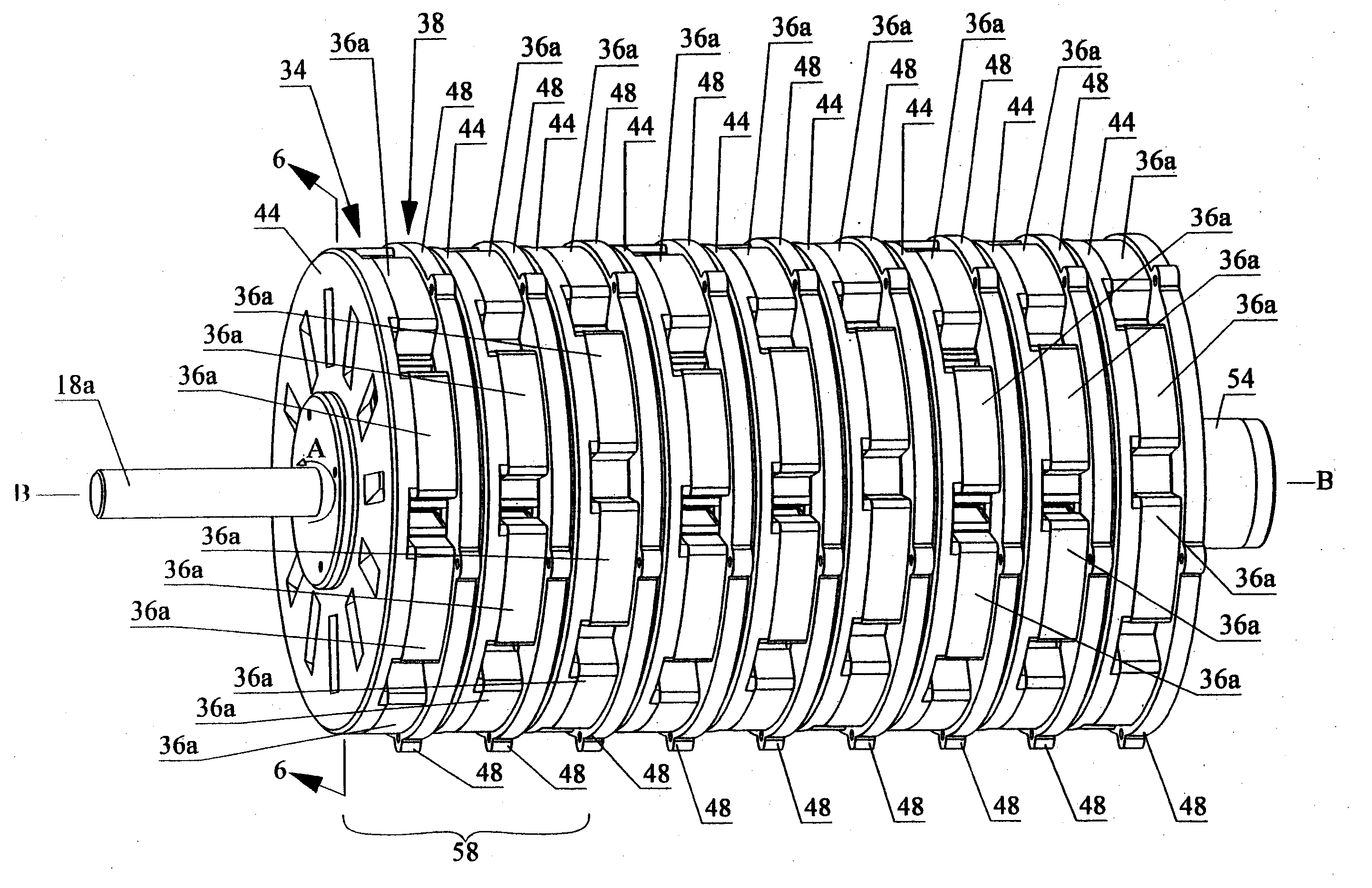

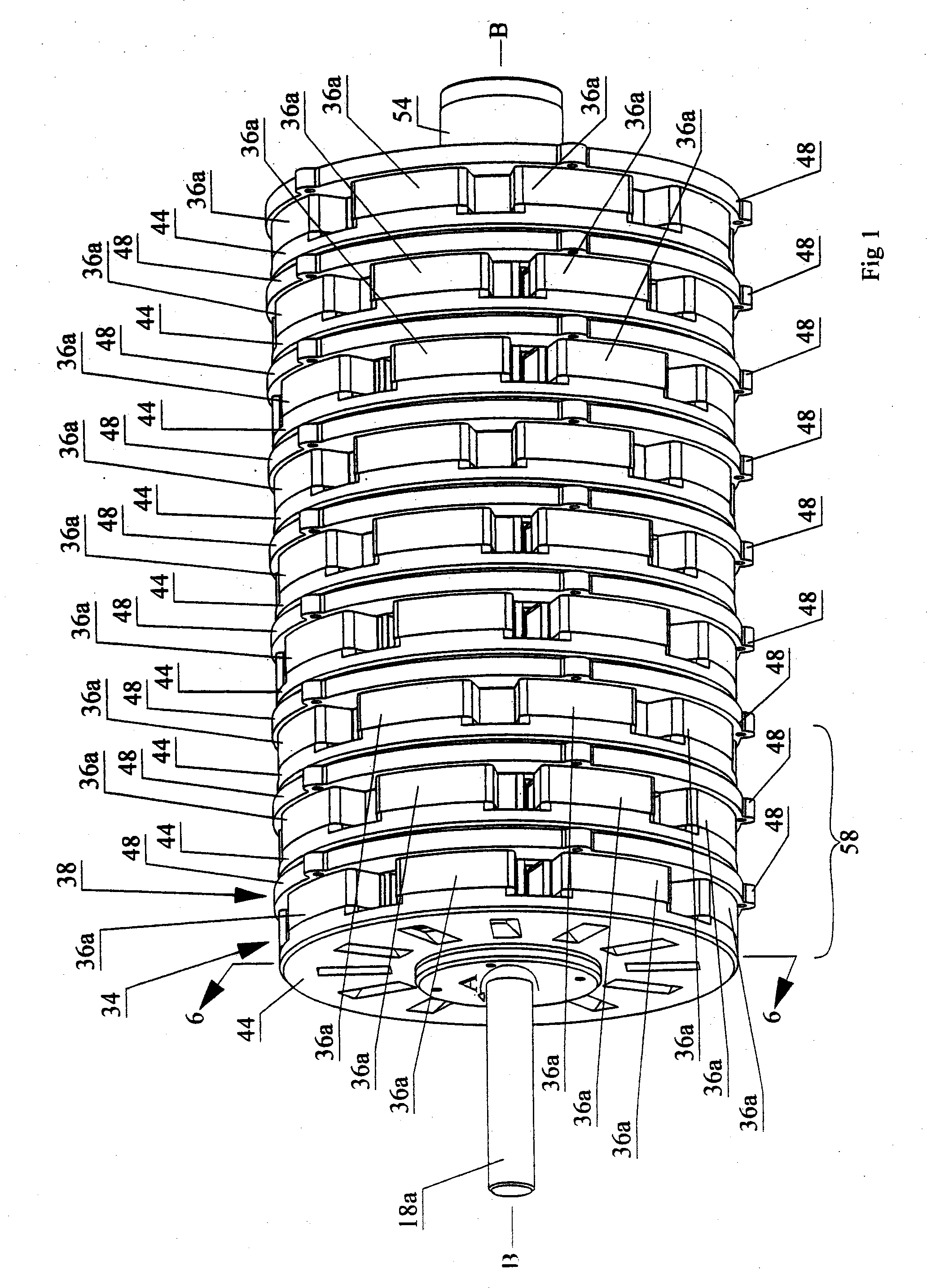

[0094] The device is a generator polyphasic multiple coils in staged staggered arrays.

[0095] Incorporated herein by reference in its entirety my U.S. Provisional Patent Application No. 60 / 600,723 filed Aug. 12, 2004 entitled Polyphasic Stationary Multi-Coil Generator. Where any inconsistency exists between these documents and this specification, for example in the definition of terms, this specification is to govern.

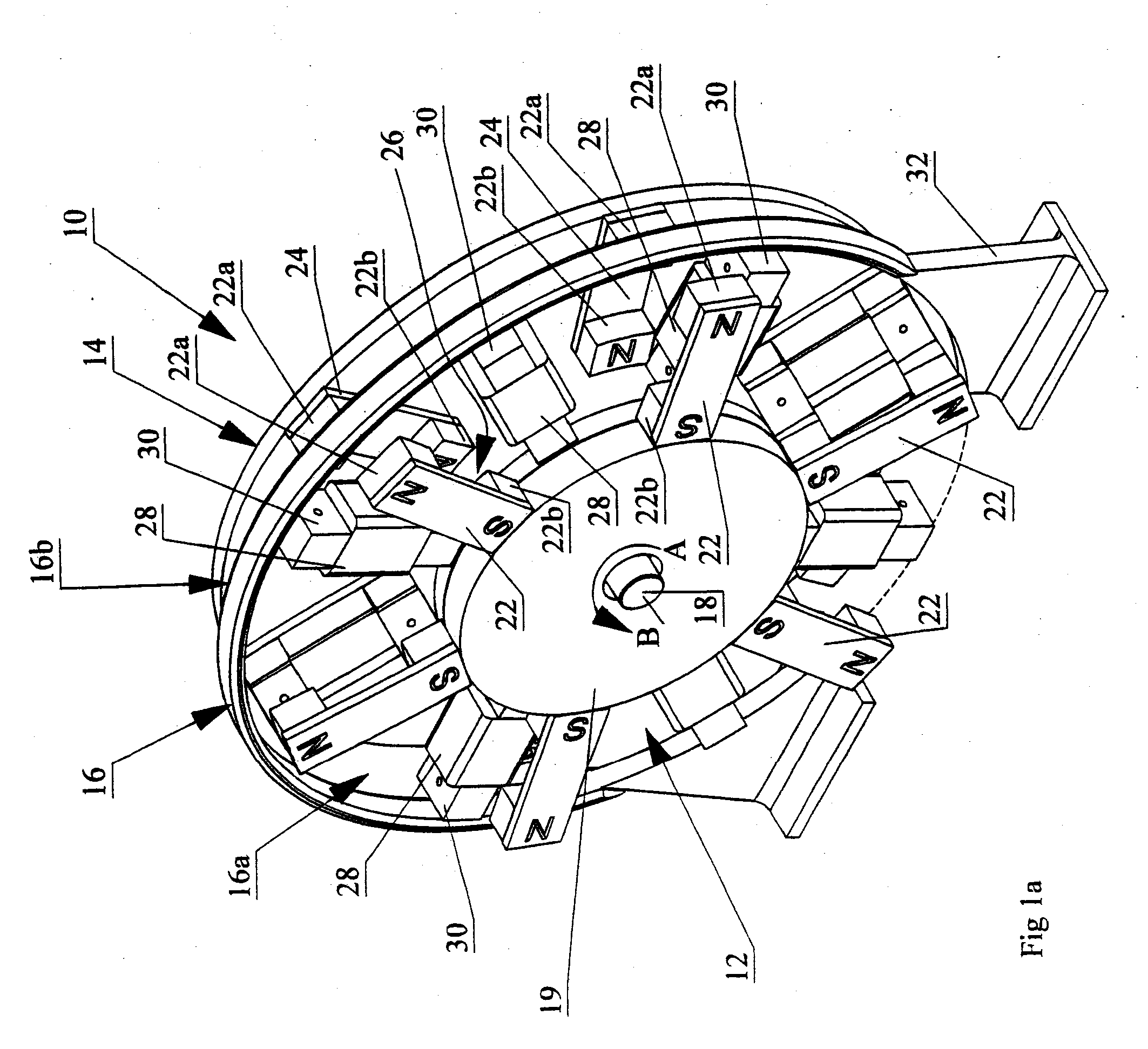

[0096] In FIG. 1a, wherein like reference numerals denote corresponding parts in each view, a single stage 10 of the polyphasic multi-coil generator according to the present invention includes a pair of rotors 12 and 14 lying in parallel planes and sandwiching there between so as to be interleaved in a plane parallel and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com