Roll-up window shade with reduced-friction drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

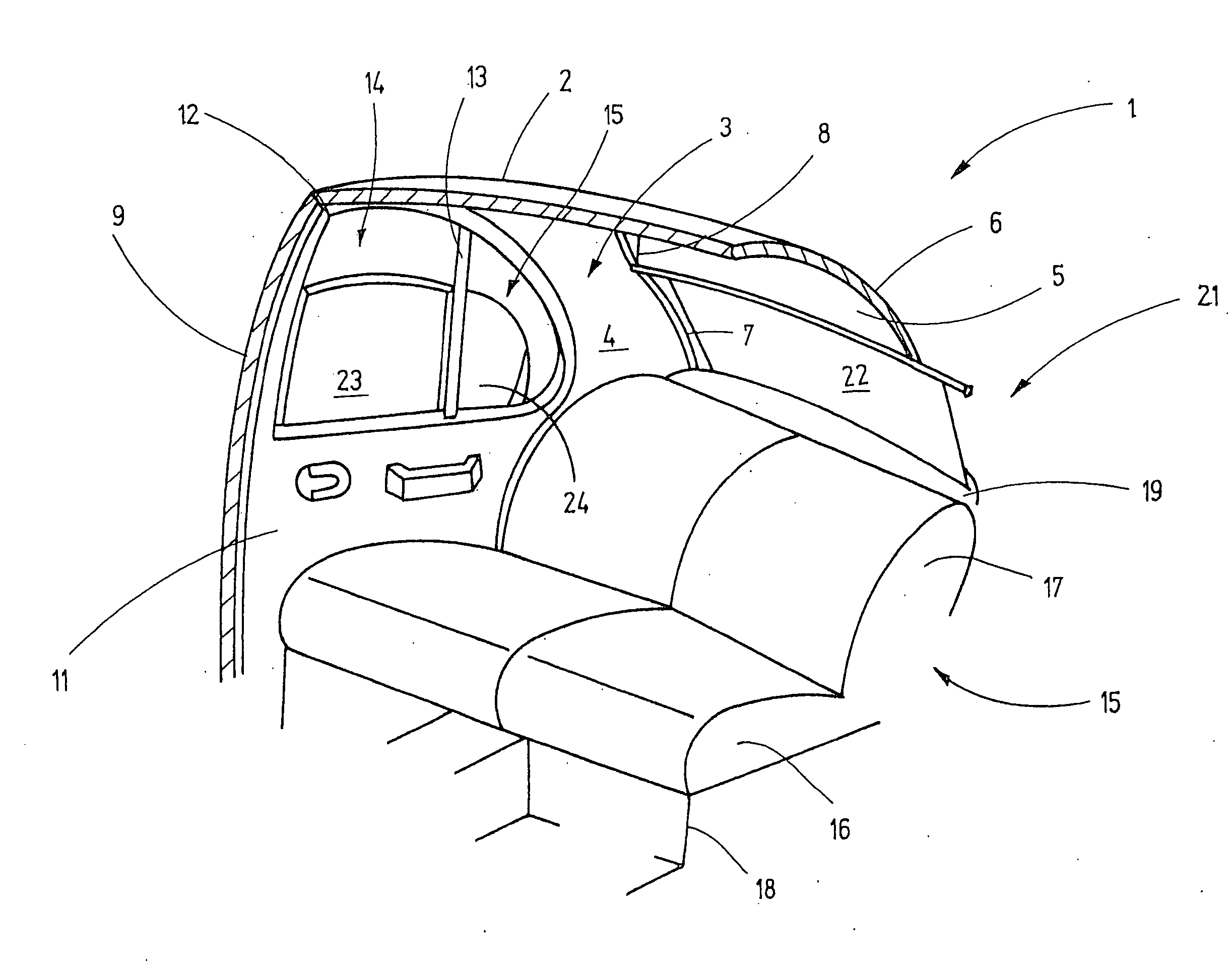

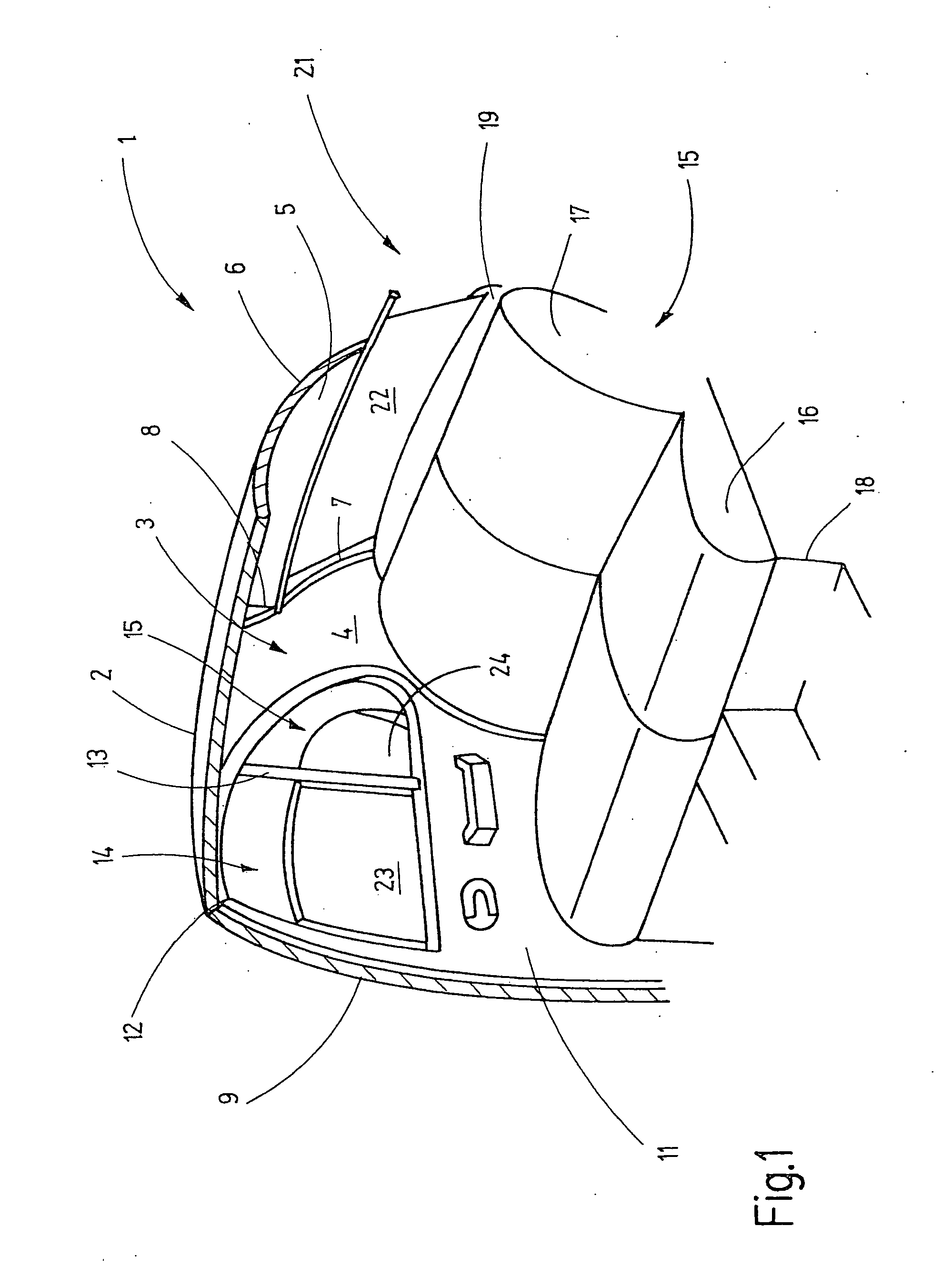

[0033] Referring to FIG. 1 of the drawings, the rear passenger compartment of a an exemplary motor vehicle is shown. The right interior side is shown in FIG. 1. The right side is the mirror image of the left interior side. Unless otherwise indicated, the explanations for the right automobile body side are also apply to the left automobile body side. The depiction in FIG. 1 is simplified; thus, for example, automobile body interior structures, such as the reinforcements, affixing elements are not shown since they are not necessary for an understanding of the invention.

[0034] The illustrated automobile body section 1 has a roof 2. A C column 3 leads downwards from a side of the roof to a car bottom assembly. A corresponding C column can also be provided on the opposite side of the motor vehicles. In this case, the interior side of the C column 3 is provided with a lining 4. A rear window 5 extends downward from the rear edge of the roof 2. The rear window 5 is bound on the upper side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com