Device for connecting bars end-to-end

a technology of connecting rods and end-to-end rods, which is applied in the direction of building reinforcements, building types, constructions, etc., can solve the problems of not being able to increase the size or strength of the screws beyond a certain limit, and the disadvantages of prior art systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

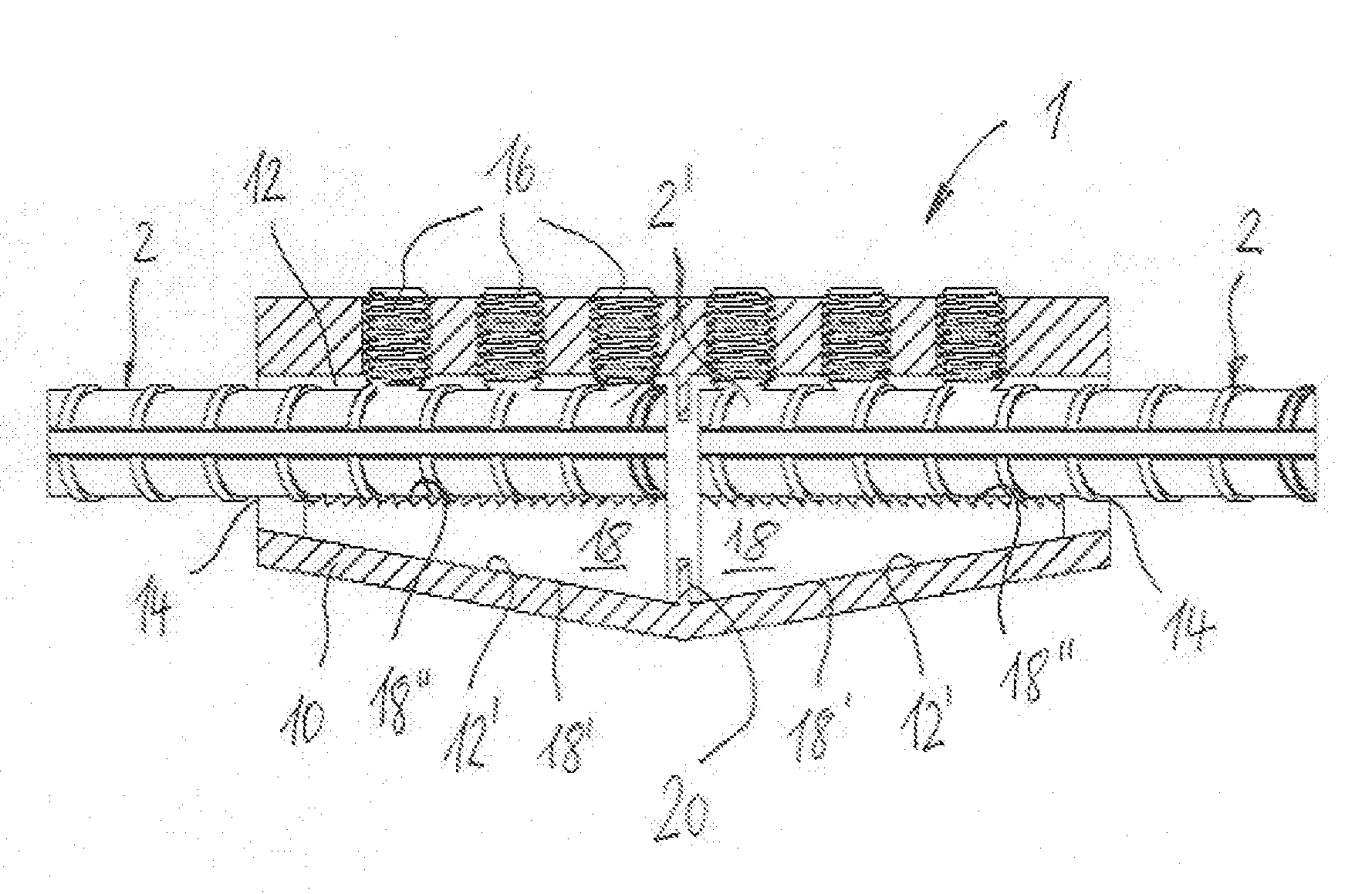

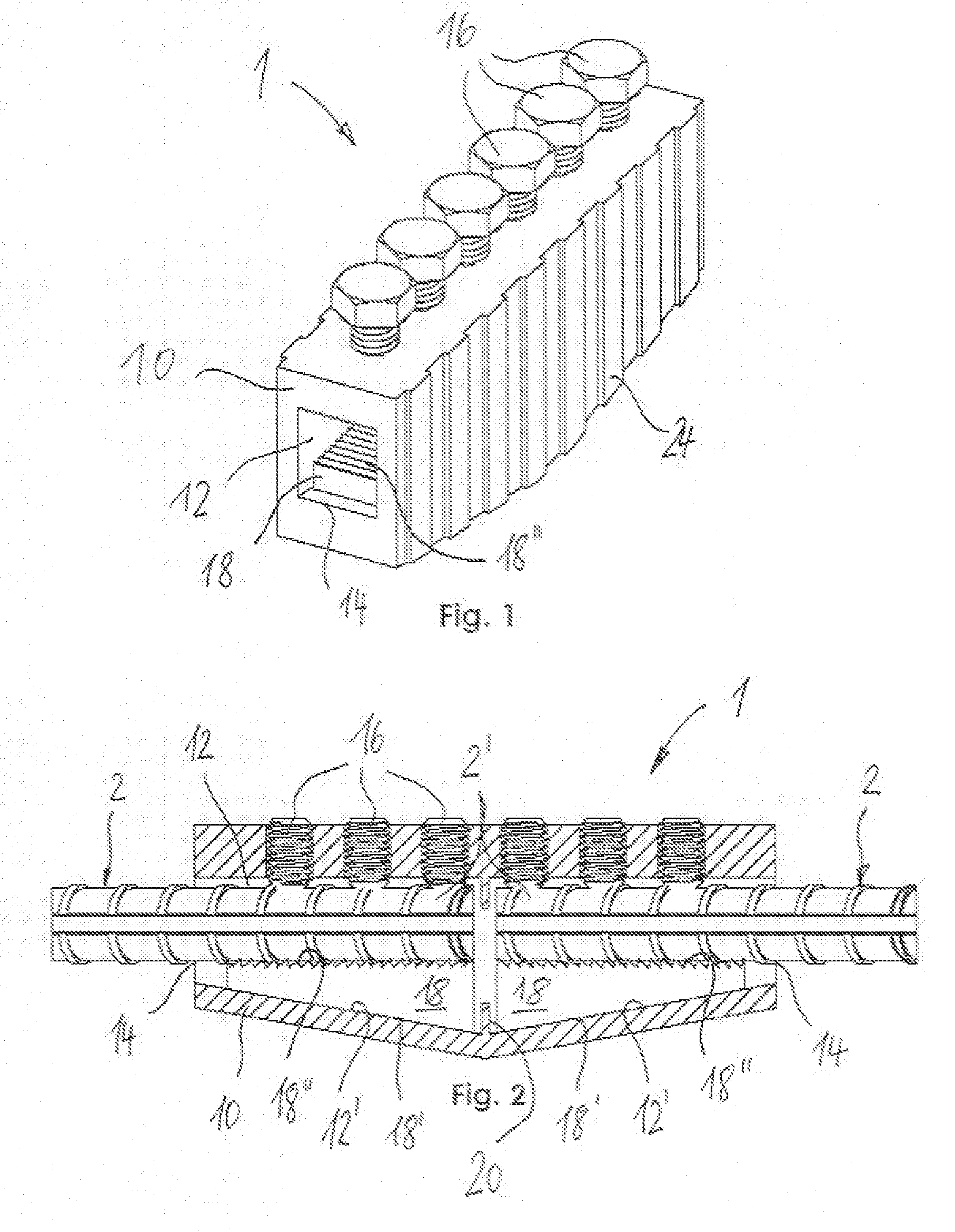

[0046]A device 1 for connecting the ends 2′ of a bar according to the present invention is schematically shown in a perspective view in FIG. 1 as well as in a cross-sectional view in FIG. 2. The device is adapted for connecting rebars and the like end-to-end as they are used in construction, for instance, in reinforced concrete structures. The device 1 comprises a hollow body 10 having an internal cavity 12 which, in the present embodiment, comprises two insertion openings 14 through which a longitudinal axis extends. The direction of extension of the longitudinal axis coincides with the direction of extension of the bars 2 to be connected (FIG. 2).

[0047]Furthermore, the device 1 comprises a plurality of clamping screws 16 which are fitted into threaded holes formed in the hollow body 10. The screws may have a reduced neck so as to produce a defined failure. As can be seen in FIG. 2, the screws 16 are adapted to press on the bars 2 inserted into the hollow body 10.

[0048]Further, the...

second embodiment

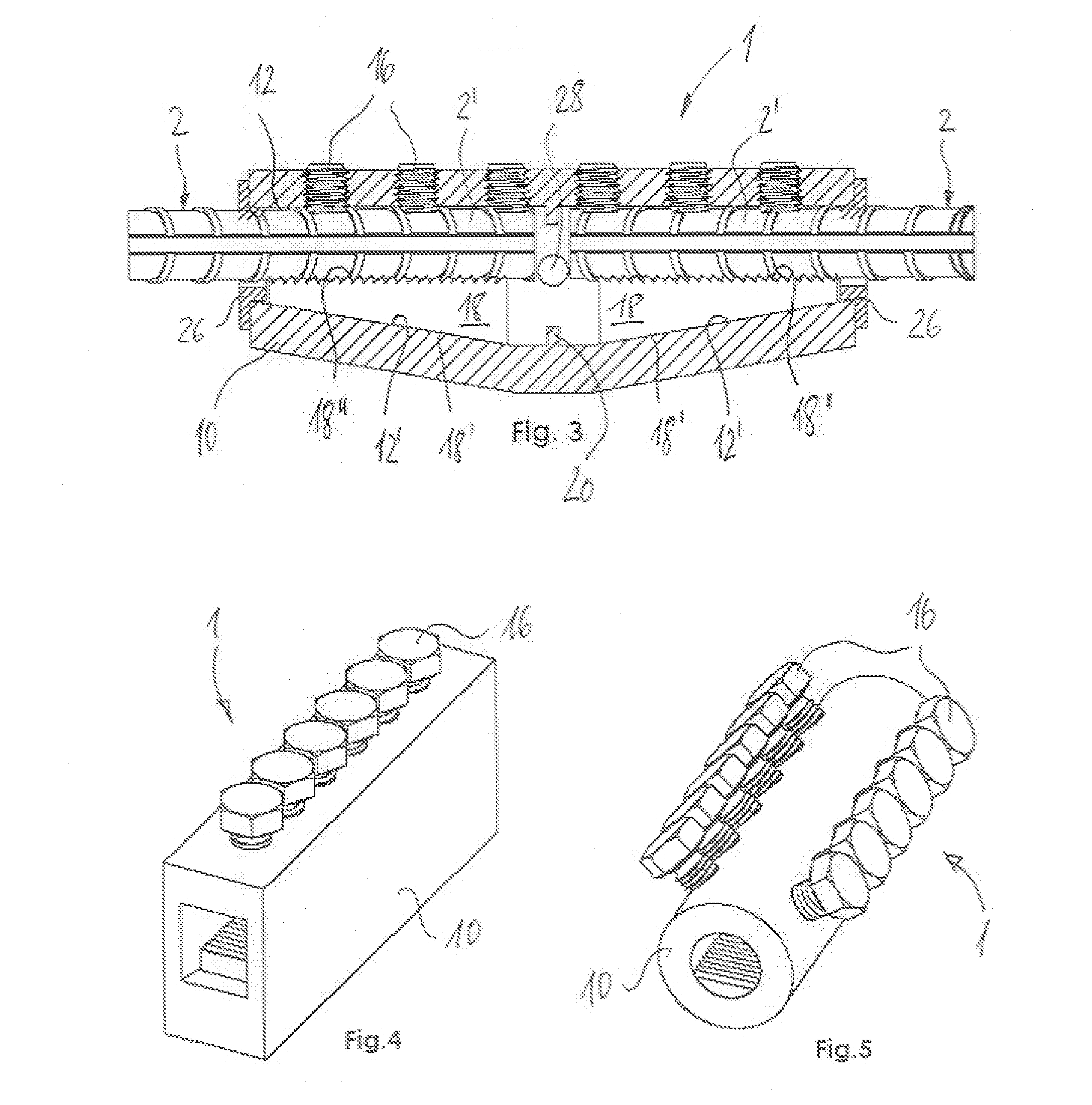

[0053]FIG. 3 relates to a second embodiment for applications where it is necessary to fill up the cavity 12 with a corrosion-protection or binding substance, end caps 26 may be provided to close the spaces at each extremity of the connection, and a hole 28 may be provided in the body 10, through which the substance may be poured or injected.

[0054]FIGS. 4 and 5 show that the external shape of the hollow body 10 may be widely varied within the present invention. Further, the device 1 may comprise one row or also plural rows of screws 16, as shown in FIG. 5.

[0055]Also the shape of the locking elements 18 is not specifically limited in the present invention. Various examples of suitable locking elements 18 are shown in FIGS. 7A to 7G. For instance, the inclined face 18′ may be flat or curved just like the gripping face 18″. Of course, further designs are possible.

[0056]FIG. 8 shows an embodiment which is adapted to connecting bars 2 having different diameters. For this purpose, the lock...

seventh embodiment

[0057]FIGS. 9 and 10 show a sixth and seventh embodiment, respectively, with additional pushing means 22 for pushing the locking elements 18 against the ends 2′ of bars 2 prior to the tightening of screws 16. This feature is illustrated in FIG. 9 with a cam 23 that is rotated around its axis. In FIG. 10 the pushing means 22 comprises a central screw 25 that pushes on the rear faces of the locking elements 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com