Sump pump control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Operation of System:

[0032]The pump operation is established with one pump as a backup pump and a pair of lead acid batteries as a backup power supply. The pump control unit serves as replacement for the utility power, in the case of AC power loss and is active for battery power as well. The control unit serves also as an alternative energy device that replaces gas-fueled generators. It is equipped with advanced pump switching logic to accommodate for normal and abnormal pump operation. The pump switching and pump control logic is active for battery power as well as AC power mode.

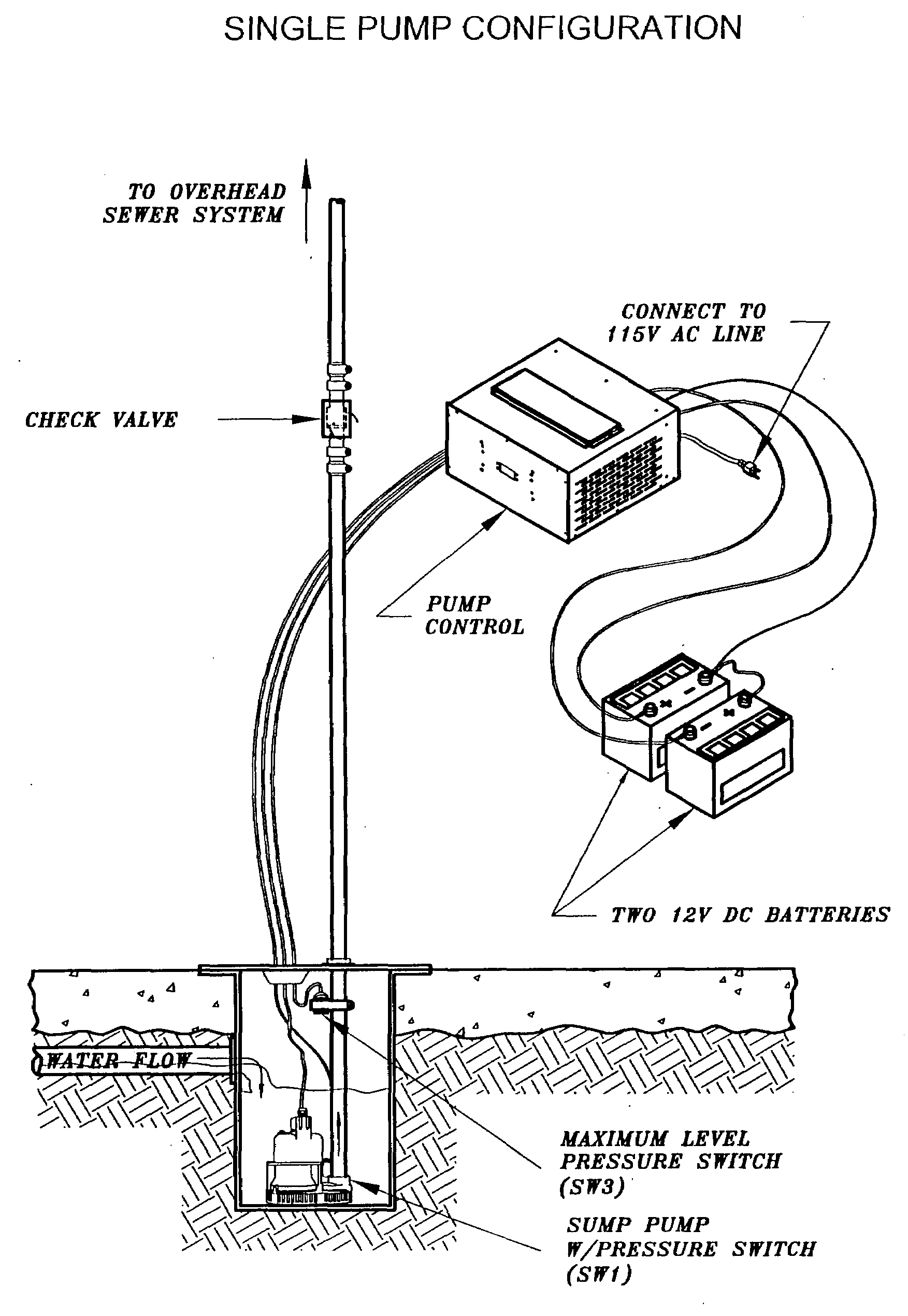

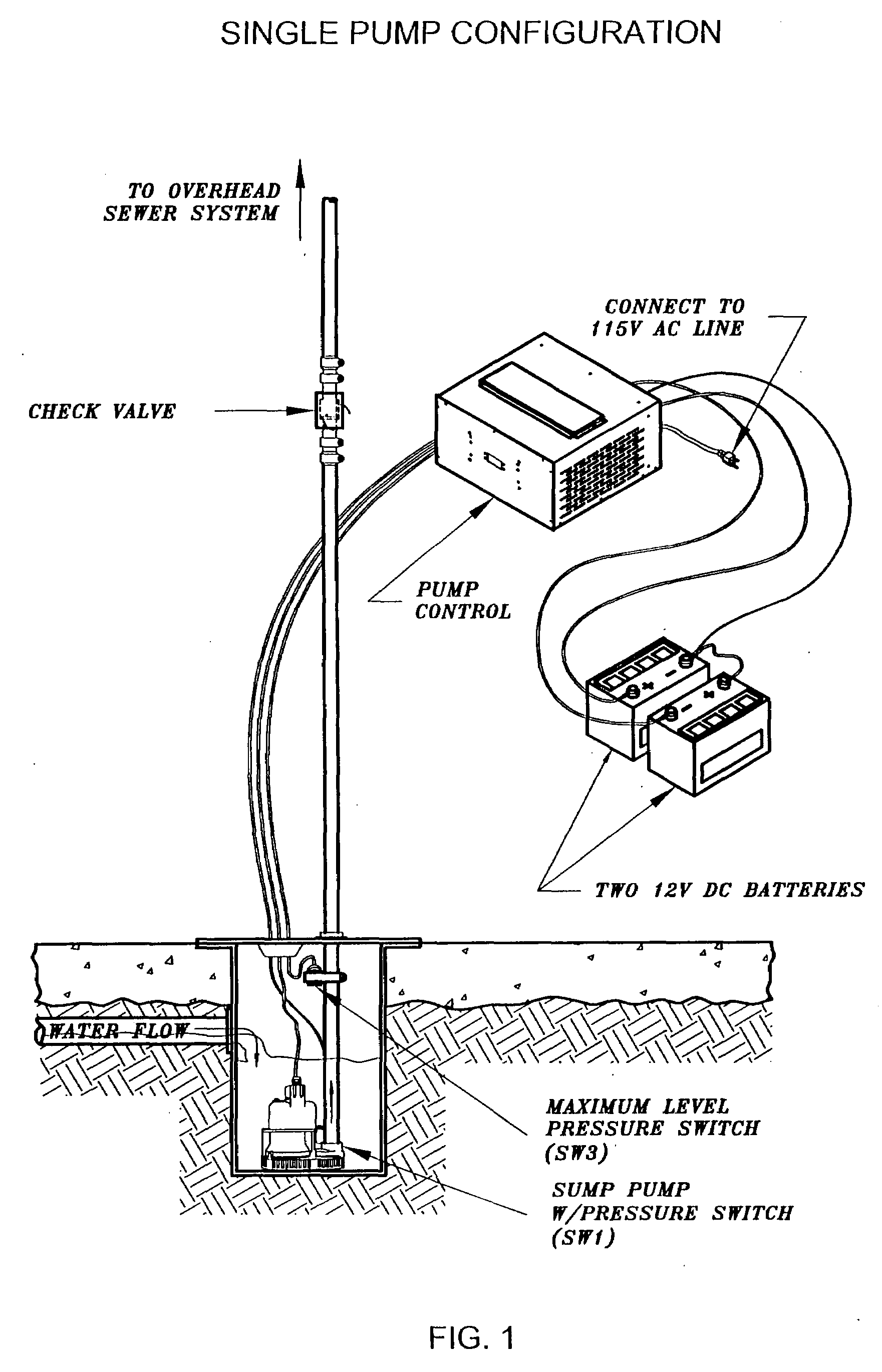

[0033]The pump control unit operates in 3 modes; the user has the option to choose between the 3 modes:[0034]1. Single pump configuration (utilizes 100% of the pump operation) (FIG. 1)[0035]2. Double pump in parallel configuration (utilizes 50% duty of each pump) (FIG. 2)[0036]3. Double pump in staggered configuration (utilizes 80% duty of primary and 20% duty of secondary pump). (FIG. 3)

[0037]Each pump has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com