Hinged derail with assisted manual lifting and method for constructing

a technology of assisted manual lifting and guiding derailment, which is applied in the direction of devices secured to tracks, railway components, transportation and packaging, etc. it can solve the problems of physical injury, heavy derail shoes that cannot be easily manually rotated between operative and inoperative positions, and steel-based derailments are difficult to manufacture and manufacture. , to achieve the effect of reducing stress on workers, no weight, and light weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

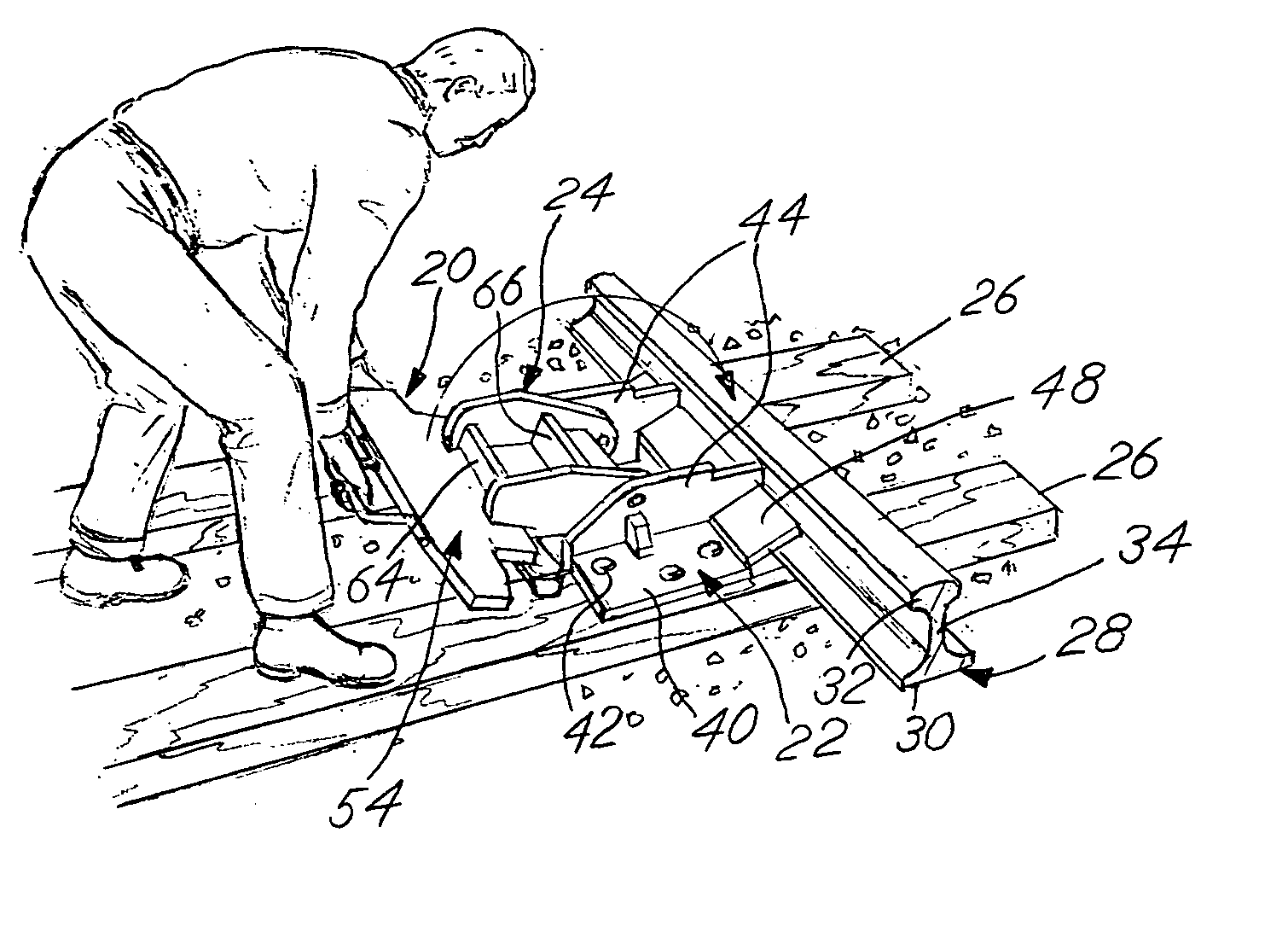

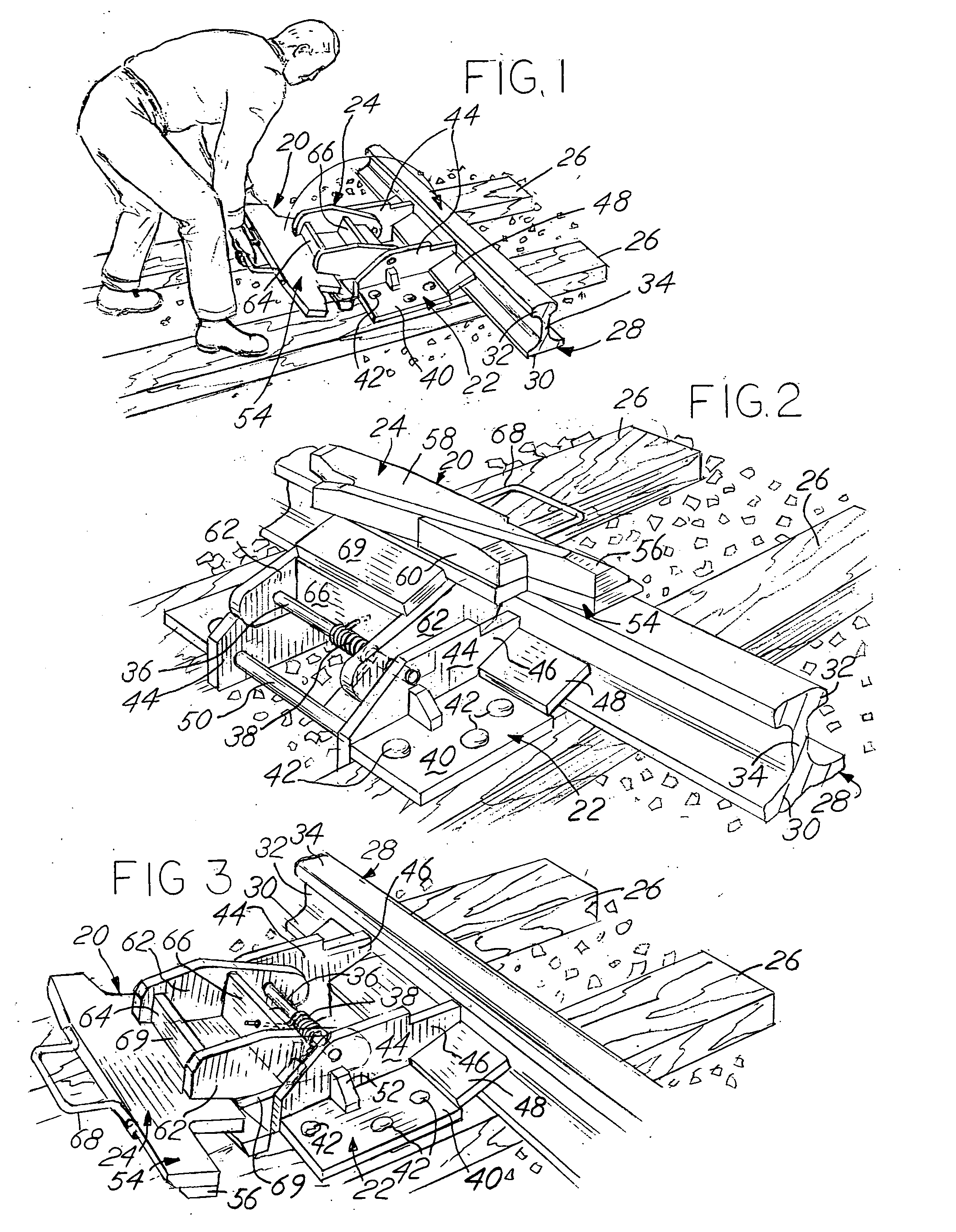

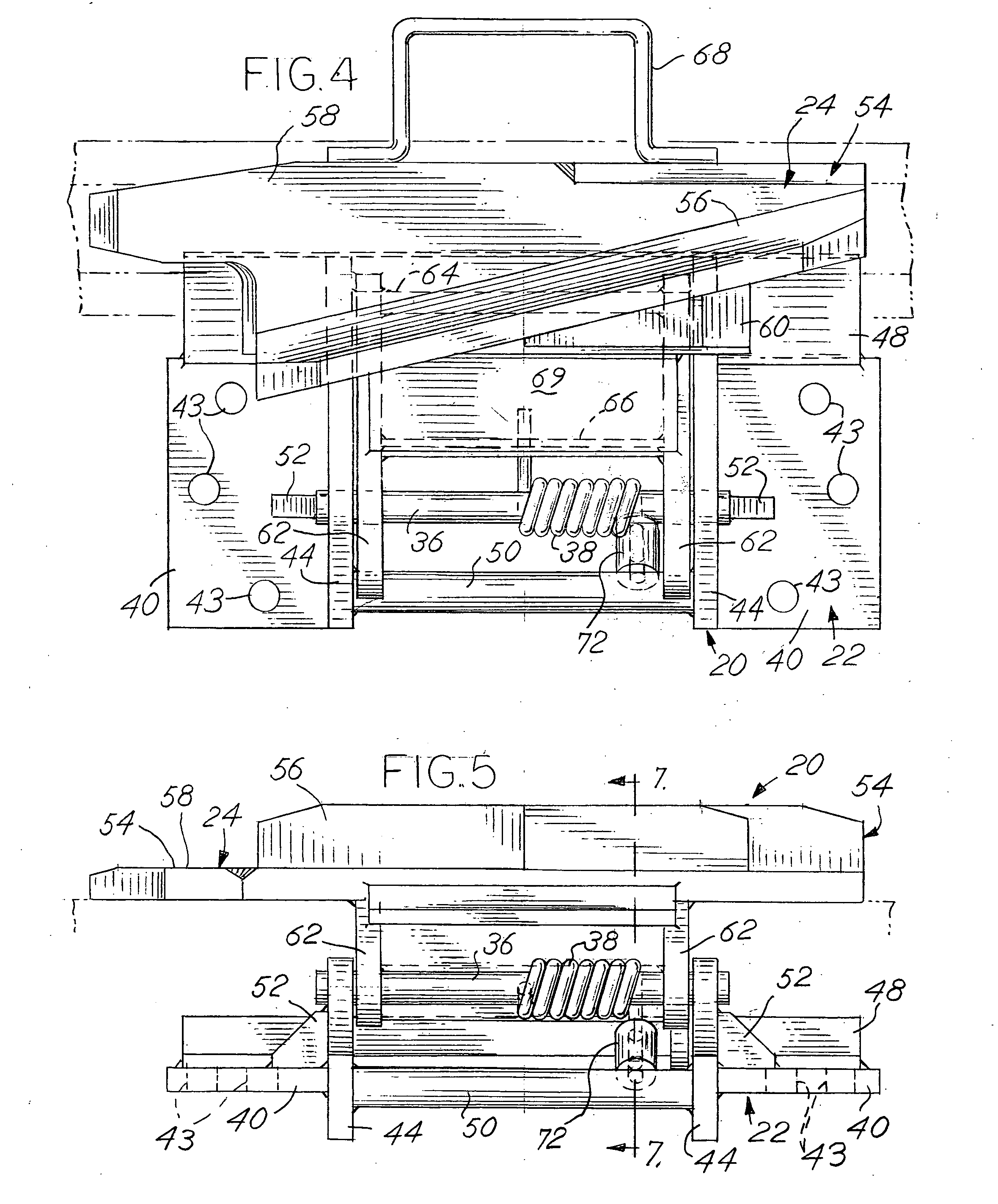

[0018]Referring to FIG. 2, the derail assembly, generally 20, of the present invention is shown in the operative or derailing position, as will be described in more detail hereinafter. The derail assembly 20 includes a derail base, generally 22, which pivotally carries a derail shoe, generally 24. FIGS. 1-3 illustrate a pair of spaced railroad ties 26 of conventional construction, usually of wood or other material which can be penetrated by conventional railroad spikes. As shown in FIGS. 1-3, a section of a railroad rail, generally 28, in a conventional manner rests upon the outer portions of the railroad ties 26, transversely thereto. The rail 28 is of conventional steel construction and includes a lower rail flange 30 which rests upon the upper portion of the railroad ties 26, an upper rail flange 32 and a generally upright web 34 which unitarily interconnects the lower rail flange 30 with the upper rail flange 32.

[0019]Referring to FIG. 2, the derail assembly 20 is shown in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com