Fit-in member

a technology of fitting parts and fitting parts, applied in the direction of electrical equipment, connection, coupling device connection, etc., can solve the problems of comparatively small operation area and difficulty in operation, and achieve the effect of simplifying construction and smoothly performing unlocking operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

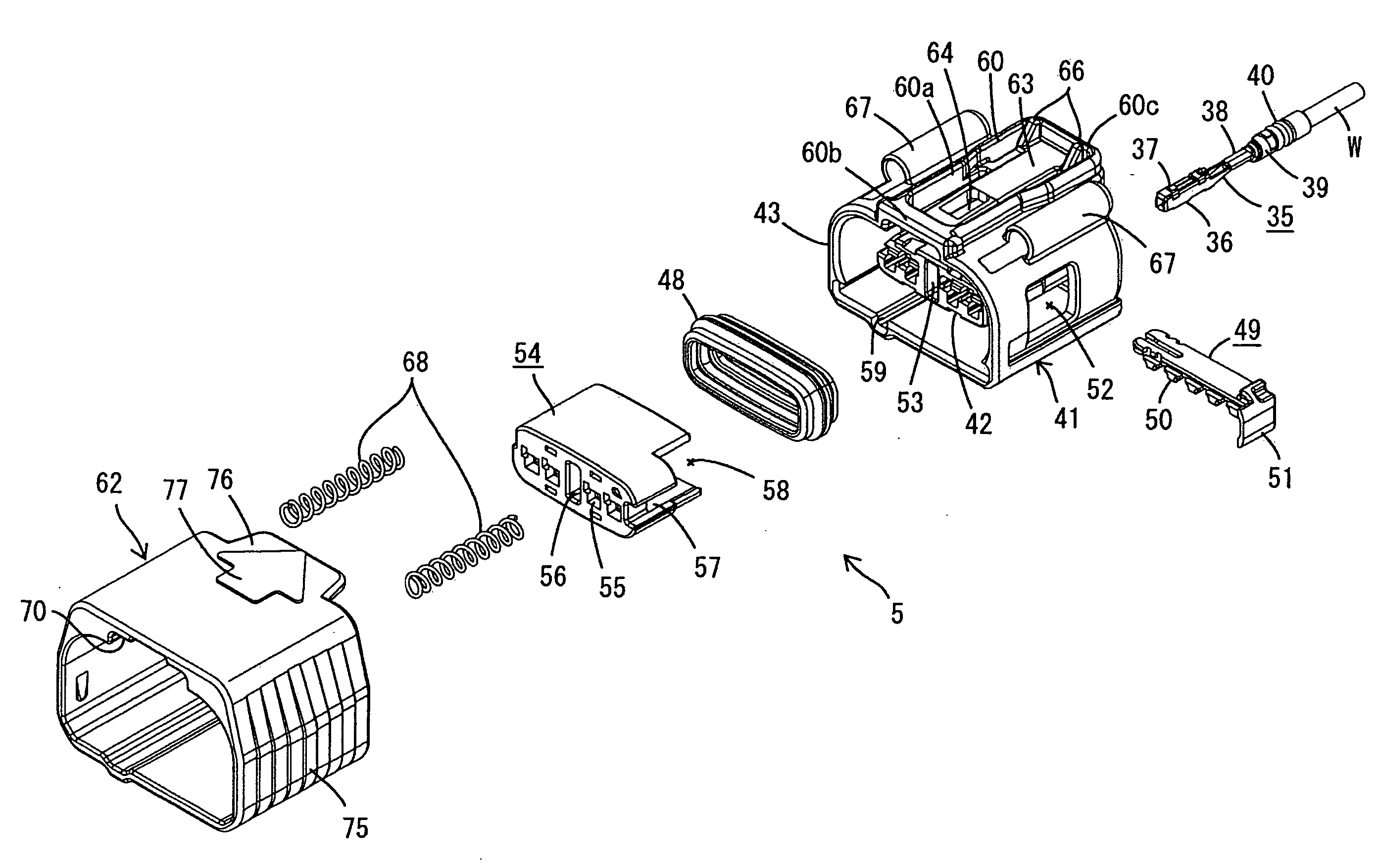

Embodiment Construction

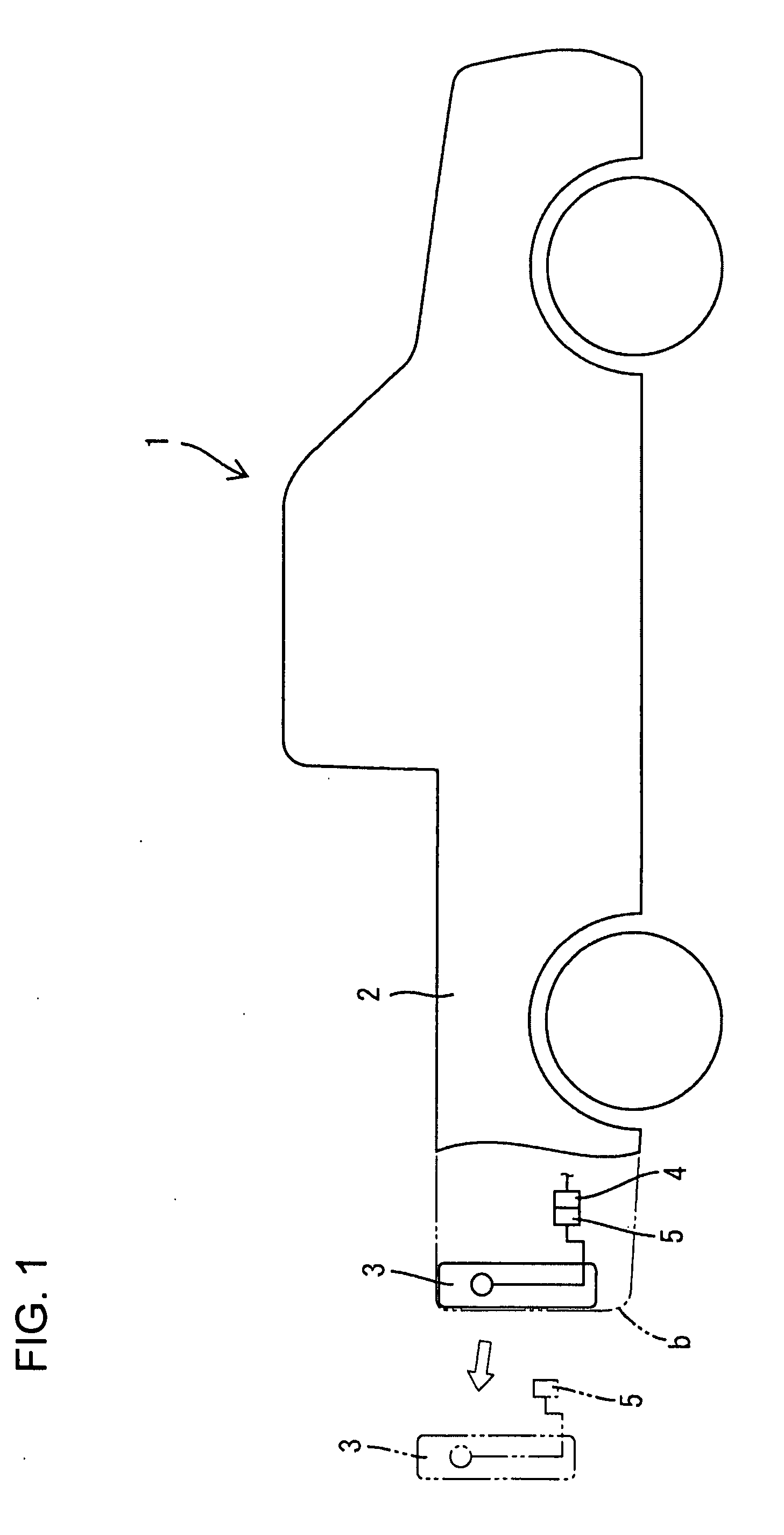

[0050] A vehicle, such as a pick-up truck, is identified generally by the numeral 1 in FIG. 1. A bed 2 is disposed in a rear part of the vehicle 1 and a tail gate 3 is disposed in a rear part of the bed 2. The tail gate 3 can be opened, closed and removed from the bed 2. An electric apparatus (not shown) called a back monitor for allowing a driver to check the situation rearward from the bed 2 is mounted on the tail gate 3. Thus a vehicle body b including the bed 2 and the tail gate 3 are connected to each other with an electric wire. Male and female connectors 4, 5 are provided midway on the electric wire for the times when the tail gate 3 is removed from the bed 2. The male connector 4 is connected with an end of the electric wire at the vehicle body b, whereas the female connector 5 is connected with an end of the electric wire at the tail gate 3.

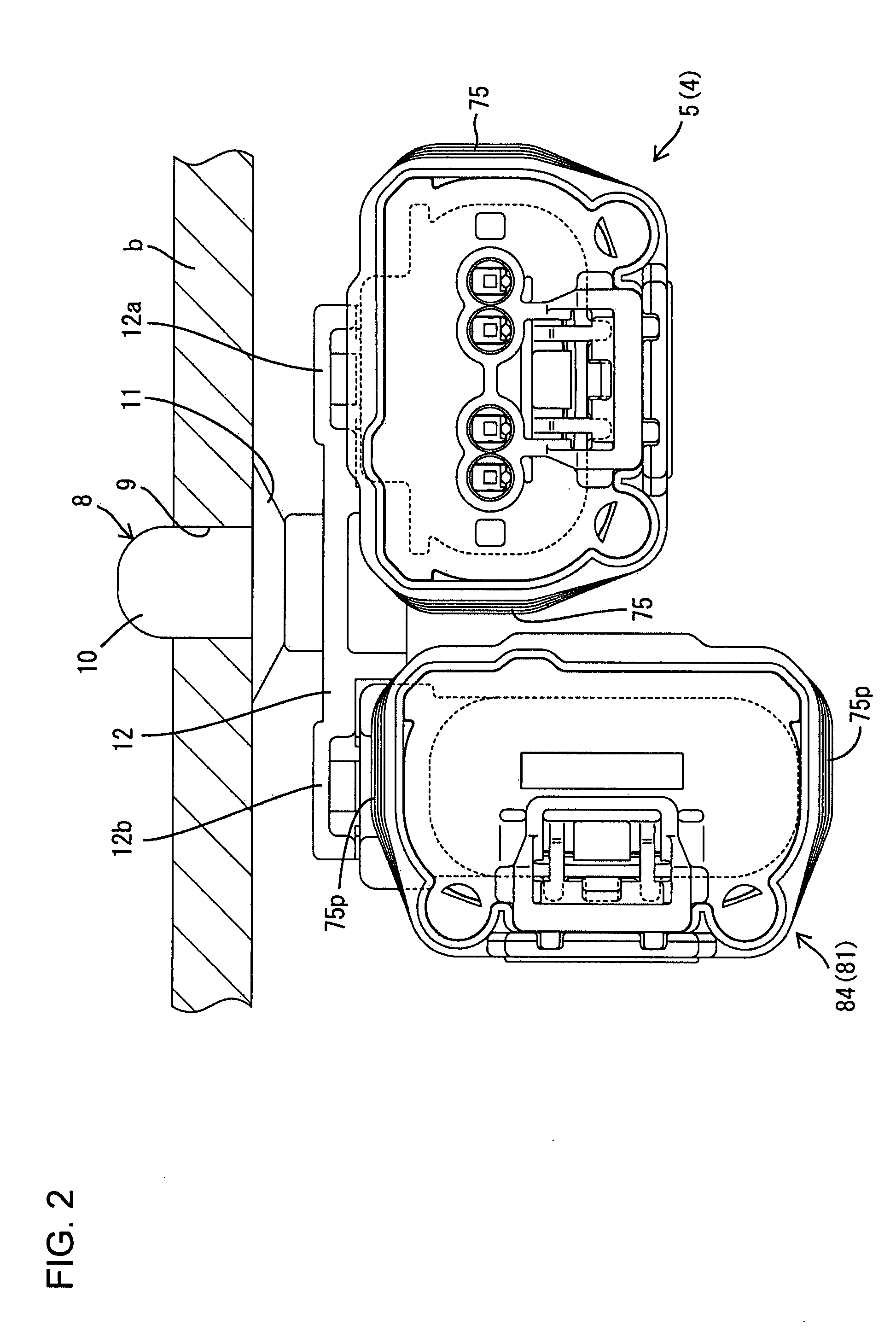

[0051] As shown in FIGS. 2 through 4, a holder 8 is fixed to the vehicle body b and is configured for holding the connectors 4, 5. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com