Geothermal Exchange System Using A Thermally Superconducting Medium With A Refrigerant Loop

a technology of thermal superconducting medium and refrigerant loop, which is applied in the direction of solar heat devices, other heat production devices, lighting and heating apparatus, etc., can solve the problems of low penetration rate of consumer markets, high capital and installation costs, and relatively high cost, so as to reduce the installation cost of ground loops and prolong the life. , the effect of enhancing cooling and heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

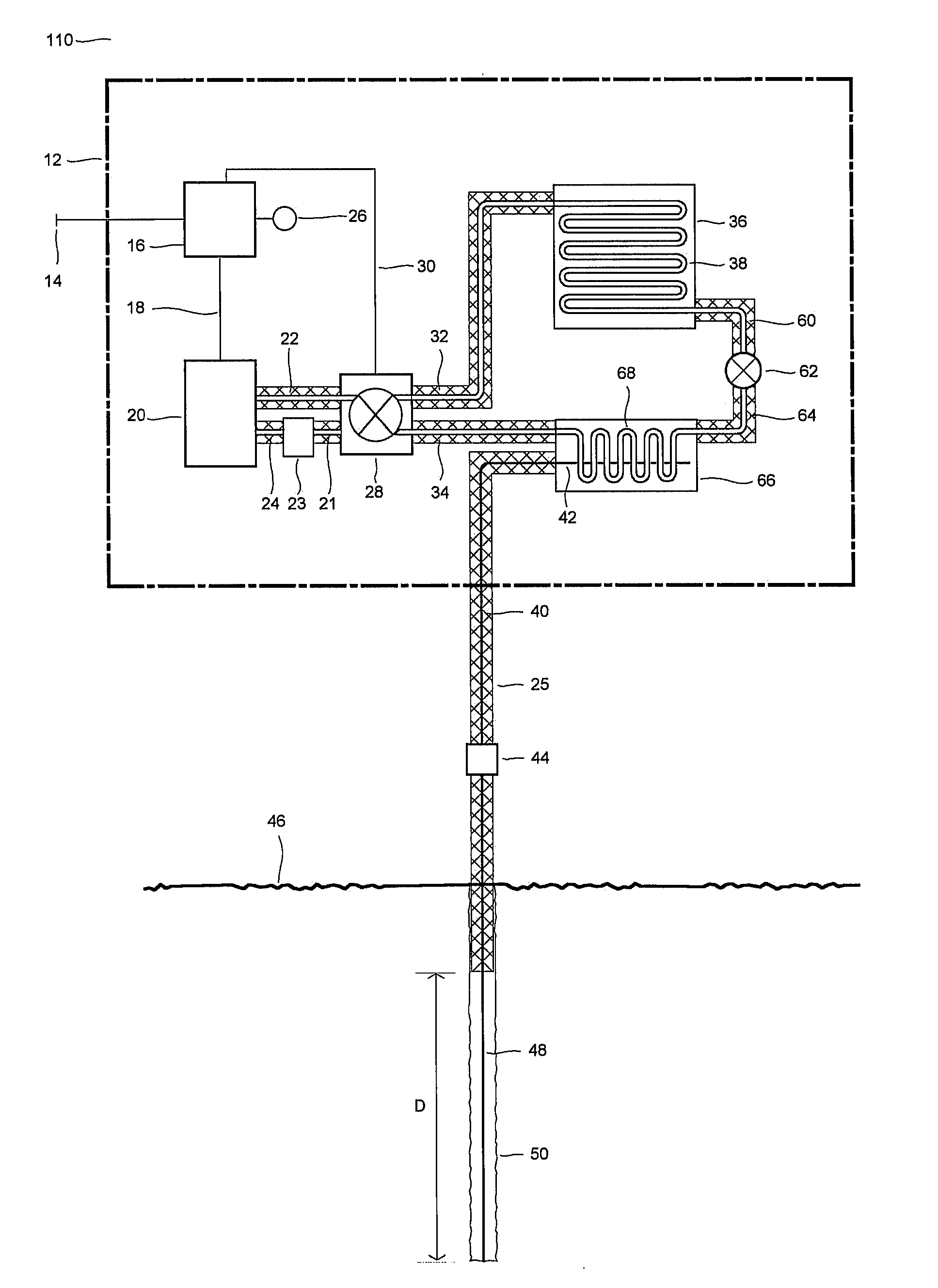

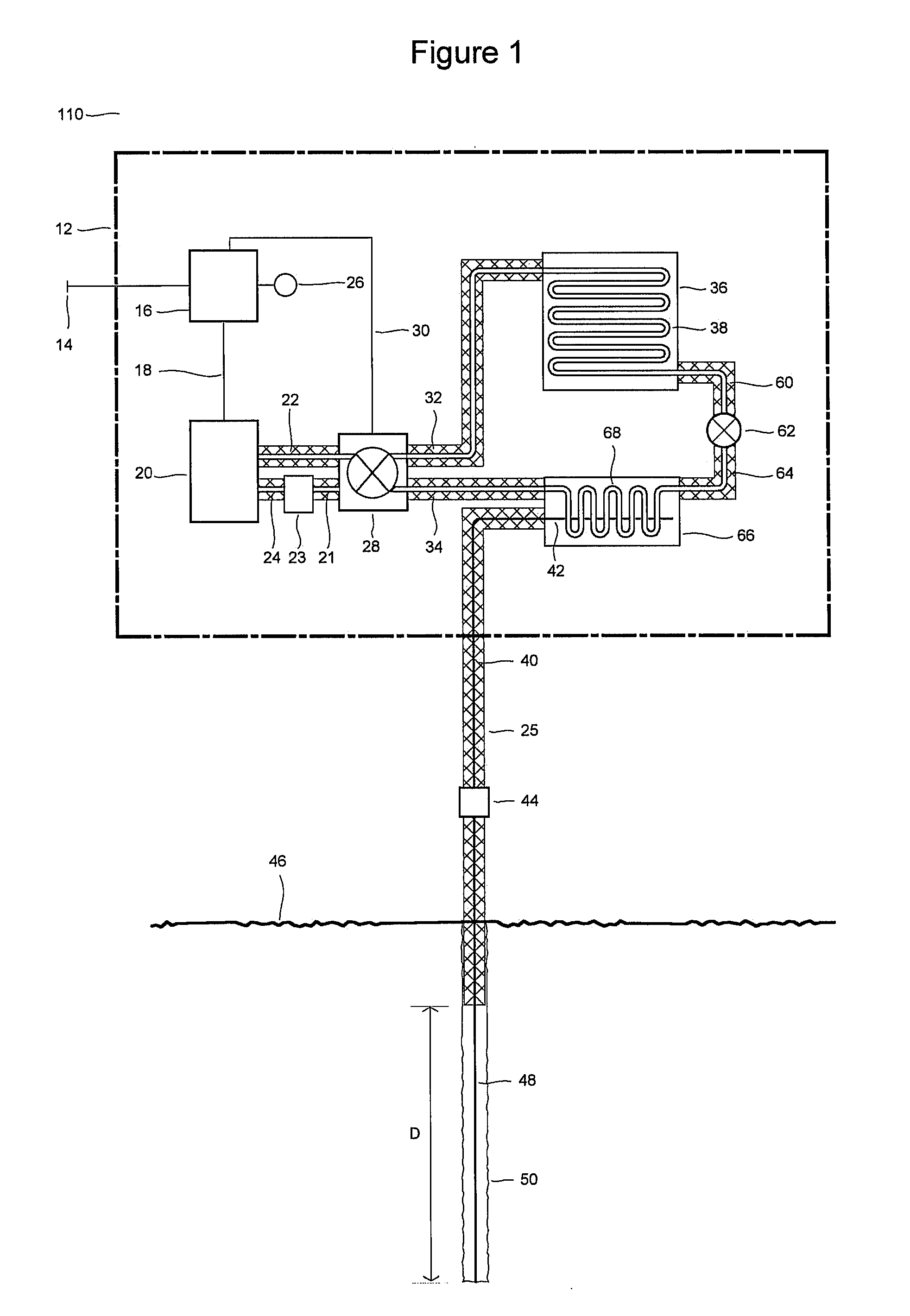

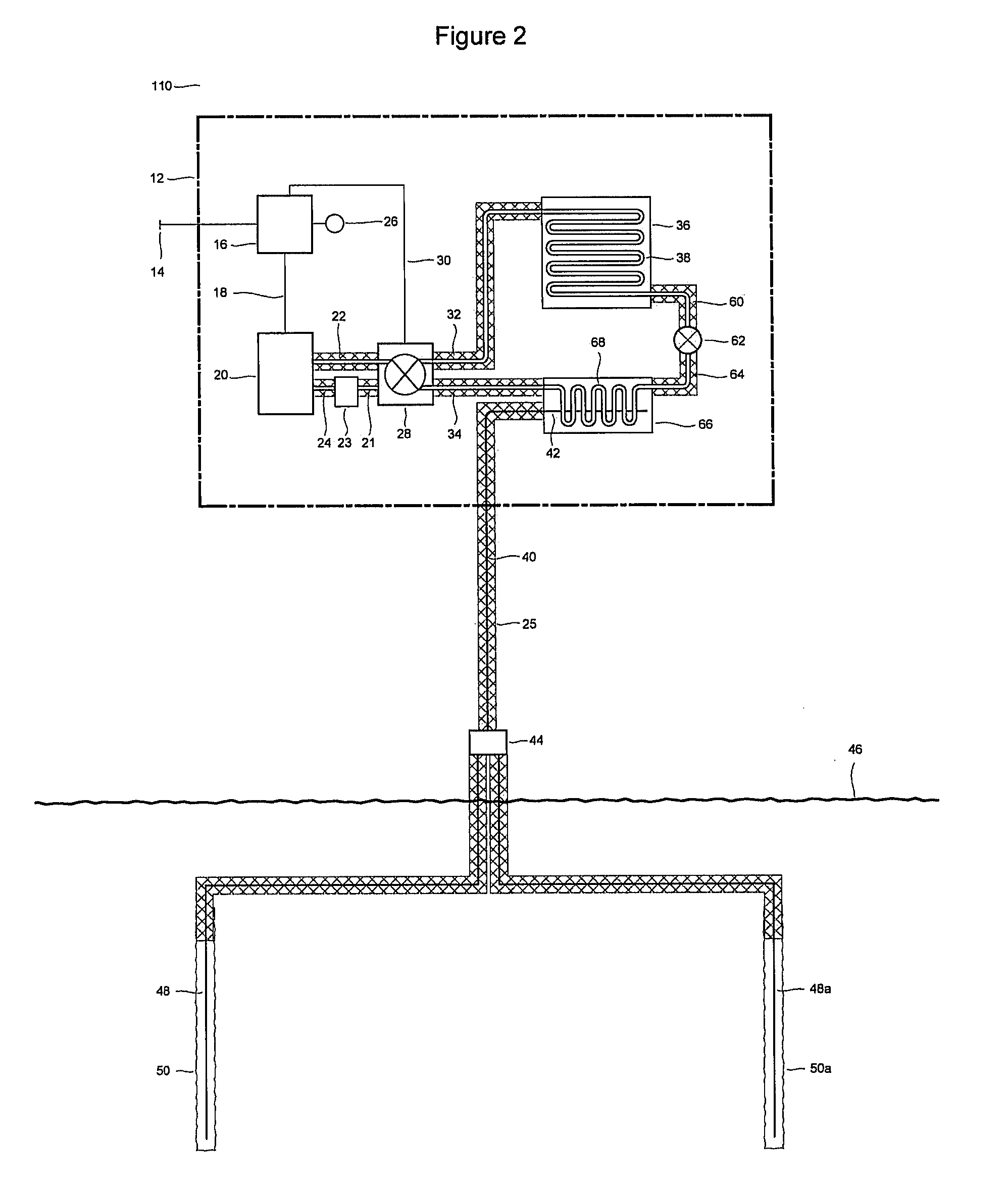

[0042] With reference to the drawings, new and improved heating and cooling devices and geothermal exchange systems embodying the principles and concepts of the present device will be described. In particular, the devices and systems are applicable for climate control within structures as well as more generally to bi-directional heat transfer to and from earth sources. The embodiments shown in the attached figures satisfy the need for a geothermal exchange system with improved thermal efficiency, lower installation cost and greater installation flexibility.

[0043] Recent advances in thermal superconducting materials can now be considered for use in novel energy transfer applications. For example, U.S. Pat. No. 6,132,823 and continuations thereof, discloses an example of a heat transfer medium with extremely high thermal conductivity, and is included herein by reference. Specifically the following disclosure indicates the orders of magnitude improvement in thermal conduction; “Exper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com