Compact system for lifting and moving pressurized tank

a technology for pressurizing tanks and compact systems, which is applied in the direction of lifting devices, hand carts with one axis, transportation and packaging, etc. it can solve the problems of single ems worker attempting to lift and move such a cylinder, significant back injury risk, and difficulty in grasping and handling by a single person, so as to ensure safety and efficiency the effect of lifting, supporting and controlling the pressurizing tank during transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

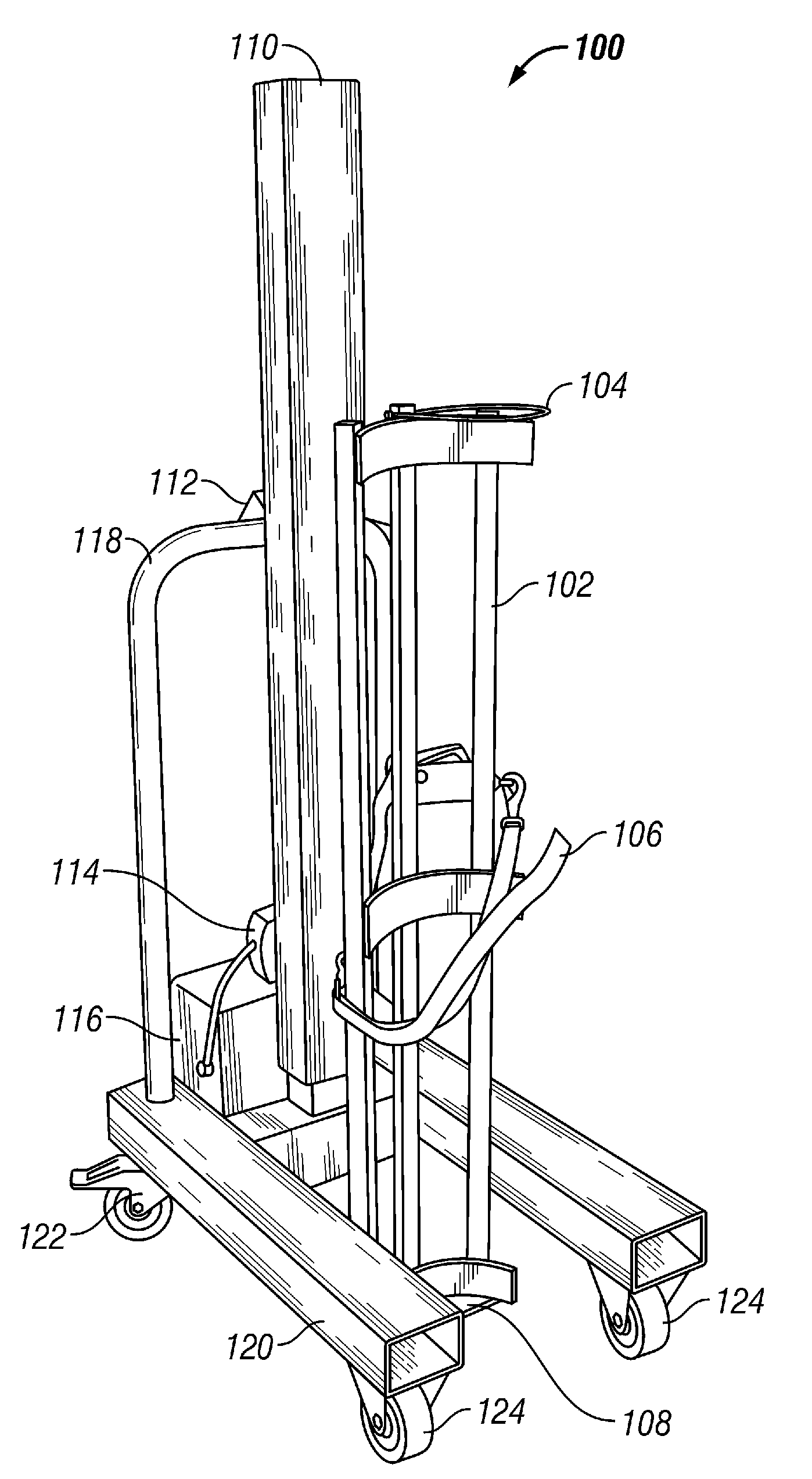

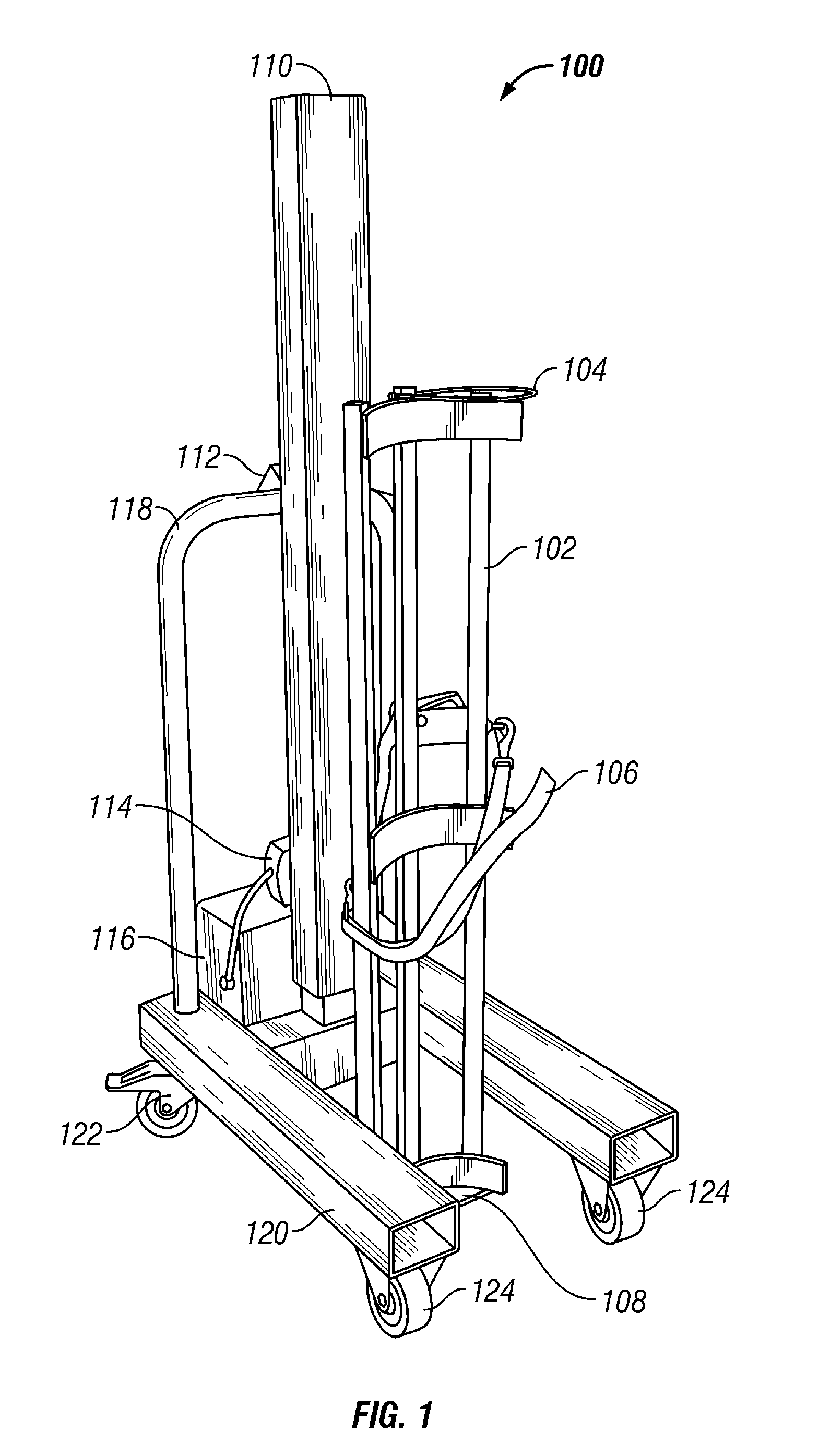

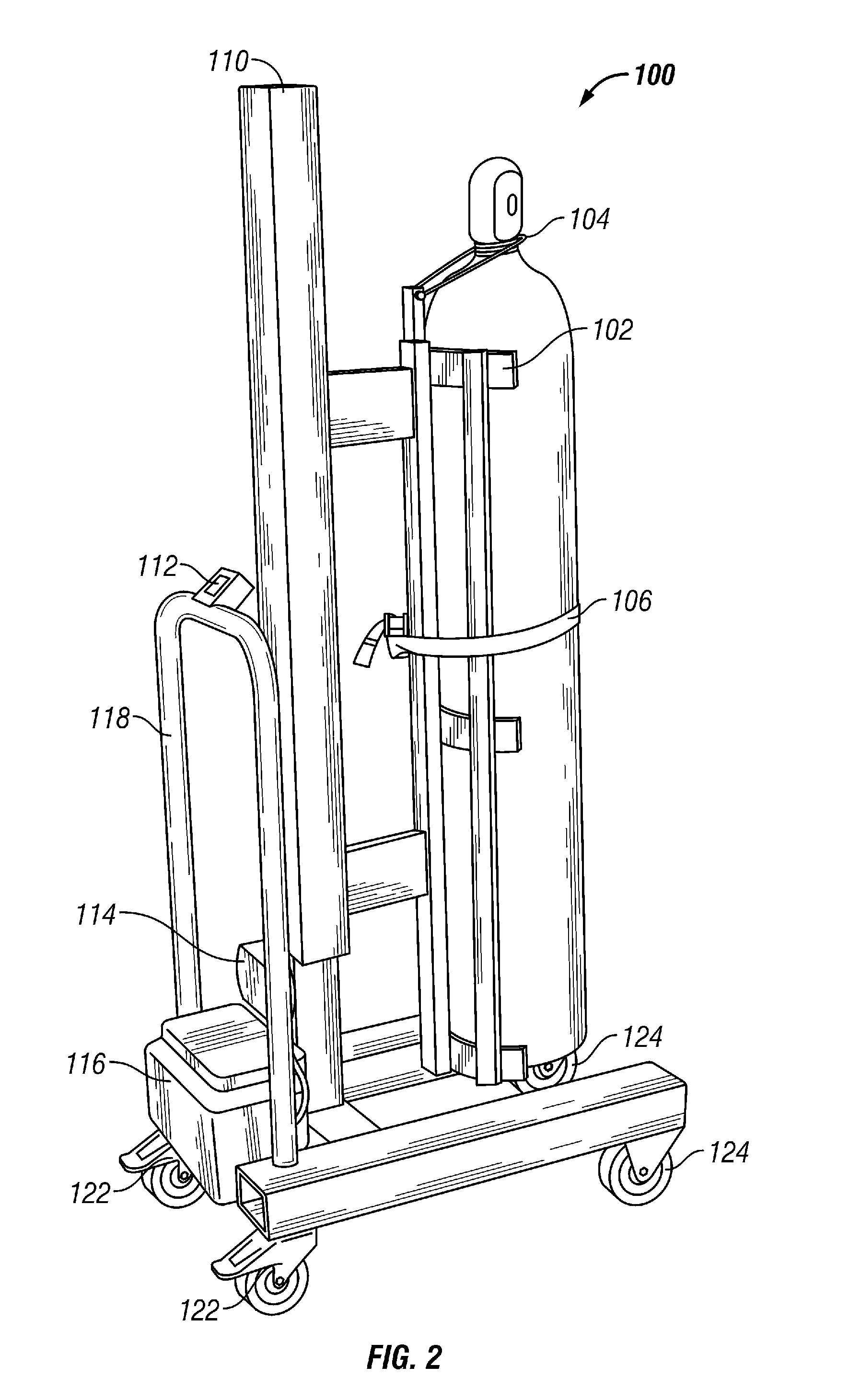

[0038]FIG. 1 and FIG. 2 illustrate a hoist 100 according to one embodiment of the present invention. FIG. 1 shows the hoist 100 without a pressurized tank attached to its cradle 102. FIG. 2 shows the hoist 100 with a pressurized tank attached to its cradle 102 and lifted for transport. The hoist 100 features a tank cradle 102 for securely attaching a pressurized cylindrical tank and supporting it during transport. The cradle 102 is attached to a linear actuator assembly 110 that provides vertical lifting motion to the cradle 102. The electrical power for the linear actuator comes from a 24V battery 116 that features its own trickle battery charger 114. The linear actuator assembly 110 is attached to a narrow base 120 that features heavy duty casters on its four corners. The front of the base 120 features fixed casters 124 while the rear features swivel casters 122 to allow for easy steering and maneuverability.

[0039]The major structural components of the hoist 100 are constructed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com