Arrangement And A Method For Controlling A Work Vehicle

a technology for working vehicles and arrangement, applied in the direction of belts/chains/gearings, gear control, couplings, etc., can solve the problems of engine cutting out, difficulty in finding an engine that precisely manages the desired power output, and different output power demands are particularly pronounced, so as to reduce the amount of hydraulic work, relieve engine load, and reduce the effect of machine productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

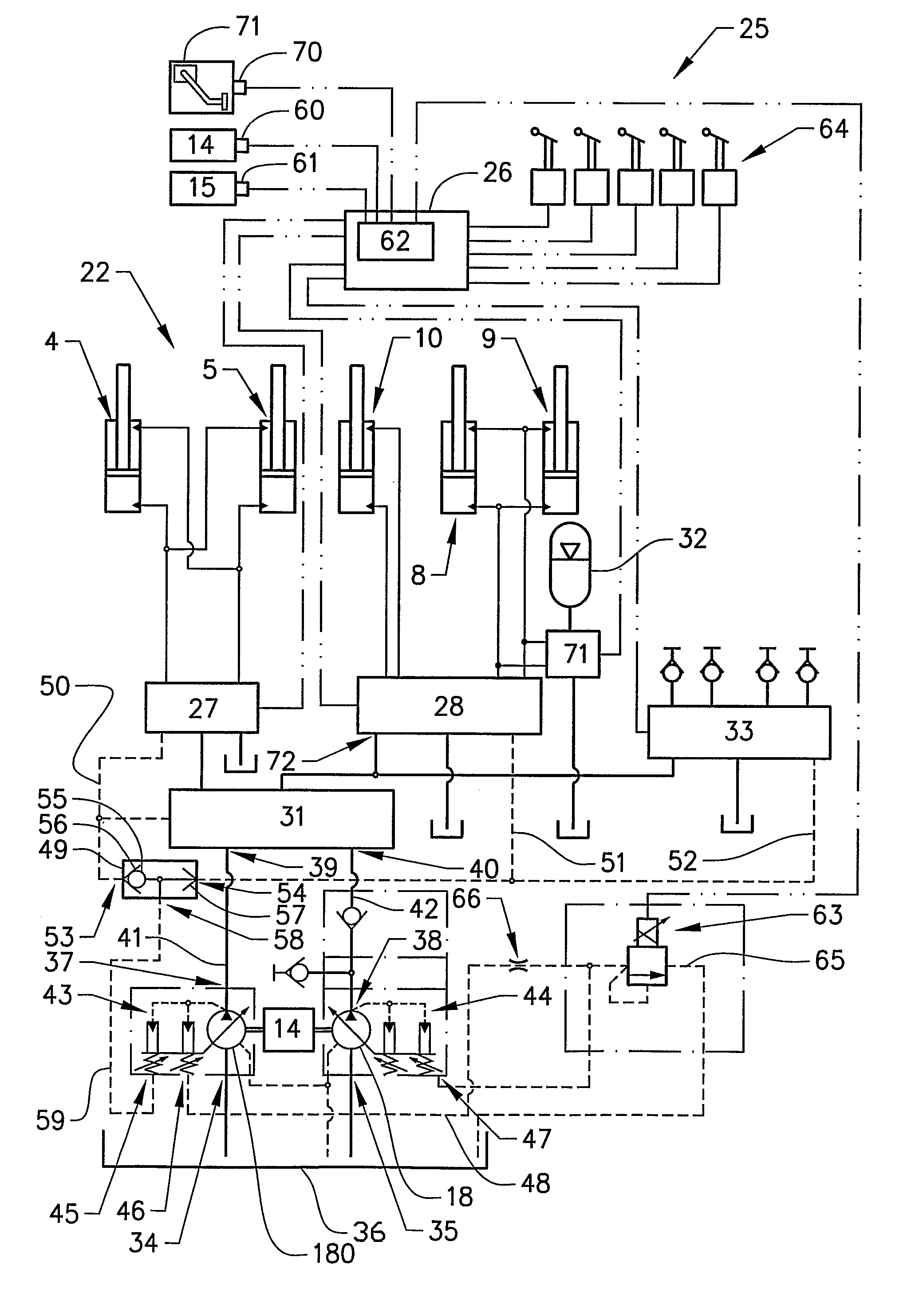

[0046] the engine speed is sensed. When the engine speed falls to a predetermined minimum, the control unit 26 will output a signal with a level as a function of the detected engine speed. Said detection means may also comprise means 70 for detecting the position of an accelerator pedal 71. Therefore, as an alternative, the control unit 26 will output a signal with a level as a function of both the detected engine speed and the detected position of an accelerator pedal 71.

second embodiment

[0047] the turbocharger pressure is sensed. When the turbocharger pressure falls to a predetermined minimum, the control unit 26 will output a signal with a level as a function of the detected turbocharger speed. As an alternative, the control unit 26 will output a signal with a level as a function of both the detected turbocharger pressure and the detected position of an accelerator pedal 71.

third embodiment

[0048] a driveline torque or output power is sensed. In this embodiment the engine torque is sensed. The pressure in a clutch in the gear box is used as a measure of the engine torque. Such clutch pressure signals are directly related to the torque being transmitted by the clutch to the wheels and by the wheels to the ground. When the torque falls to a predetermined minimum, the control unit 26 will output a signal with a level as a function of accessible engine torque. As an alternative, the control unit 26 will output a signal with a level as a function of both accessible engine torque and the detected position of an accelerator pedal 71.

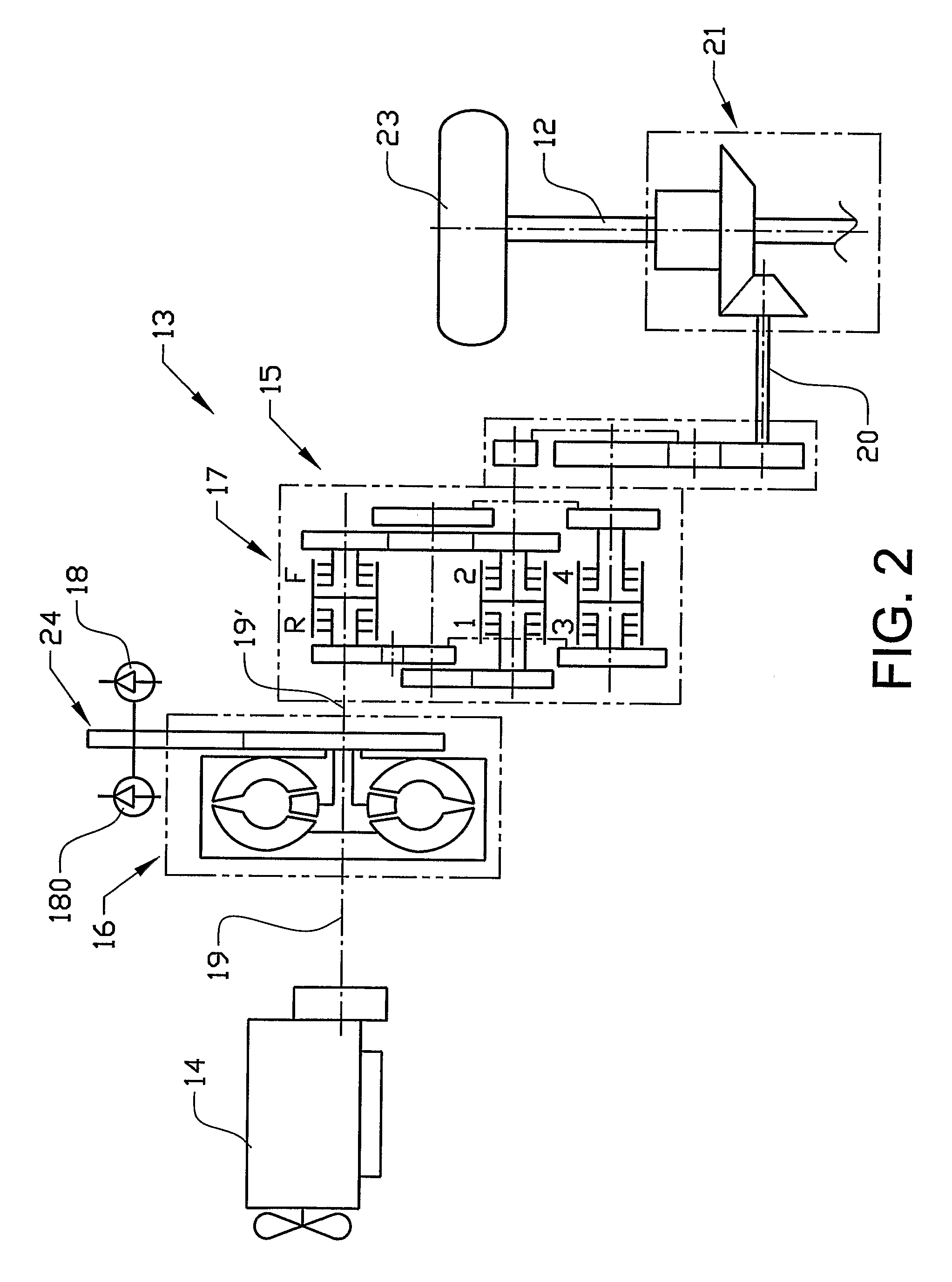

[0049] Said detection means further comprises means 61 for detecting a gear state in the gear box 15. More specifically, the detection means 61 detects a neutral state in the gear box 15. If the driver uses the hydraulic system 22 for a certain work operation when the vehicle is standing still, the driver normally puts the gear in the neutral sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com