Limited loss laminar flow dampers for heating, ventilation, and air conditioning (HVAC) systems

a technology of laminar flow and heating, which is applied in the direction of ventilation systems, lighting and heating apparatuses, heating types, etc., can solve the problems of reducing worker productivity, biological problems in indoor environments that have received considerable attention, and the operation of hvac systems is affected by biological contamination by bacteria, molds, viruses, etc., to achieve sufficiently accurate flow measurement, facilitate relatively simple flow measurement techniques, and inhibit inadvertent pressure drop and turbulence in flows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

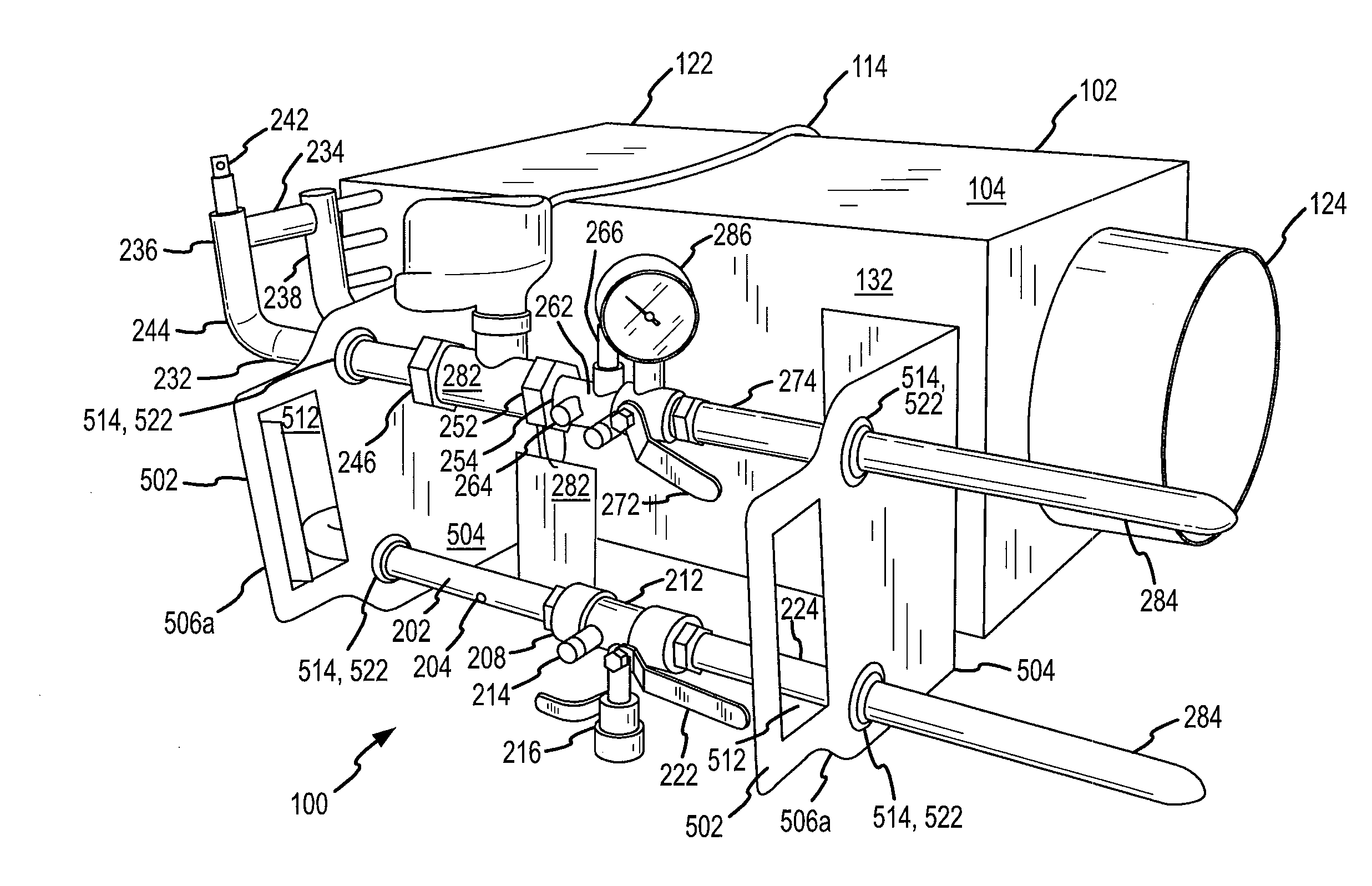

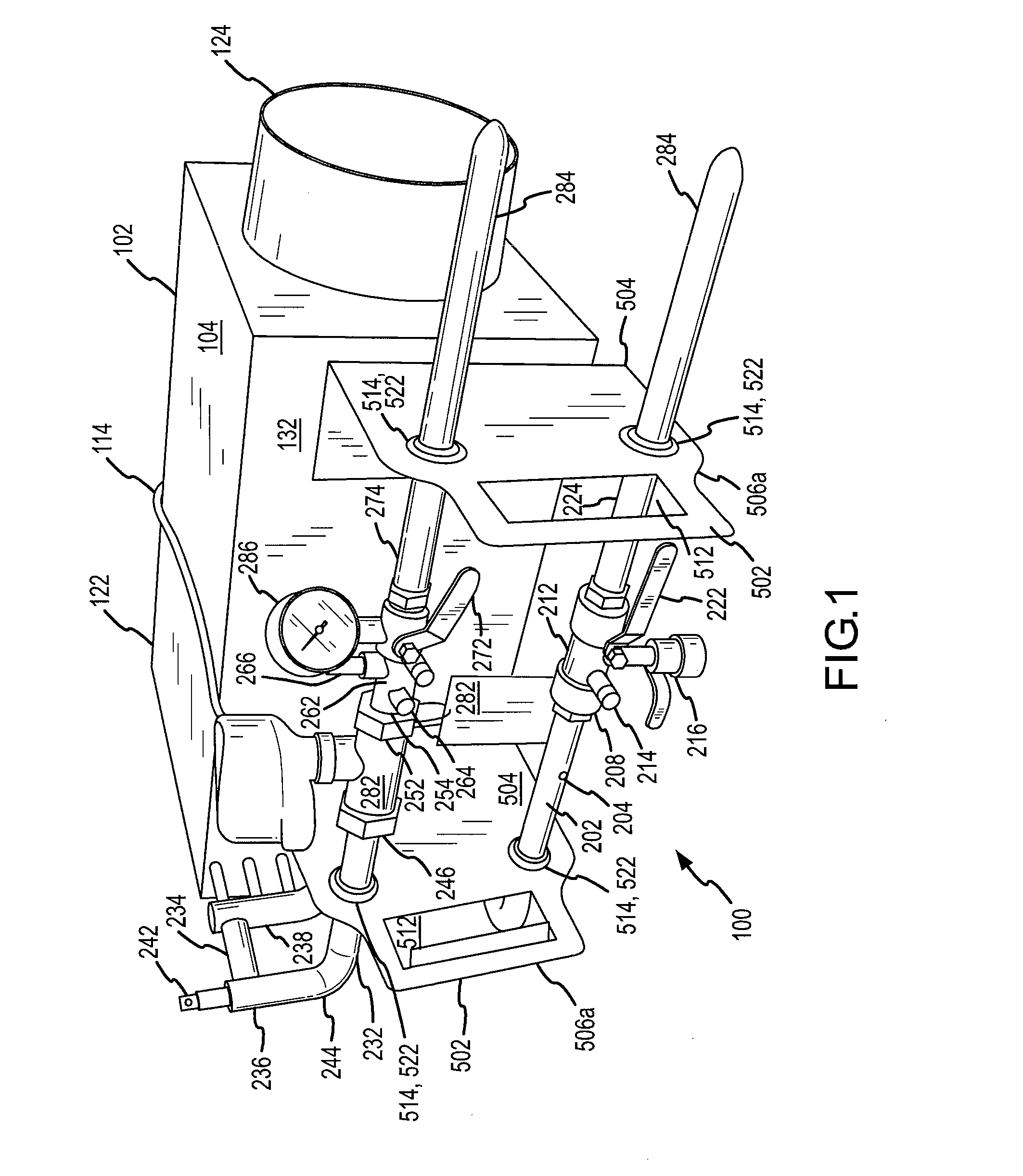

[0044] The perspective view of FIG. 1 illustrates a fully-functional HVAC terminal unit referred to by the general reference character 100. The fully-functional zone-control unit 100 depicted in FIG. 1, which illustrates one embodiment of the present invention, preferably includes a mechanical terminal unit 102 having a casing 104 visible in FIG. 1. The casing 104, which can be made from various materials of differing thicknesses, is frequently made from galvanized sheet steel material. Frequently, the casing 104 is lined with a thermal insulation material, not visible in FIG. 1, which may be chosen from various different types such as fiberglass insulation, rigid duct board fiber insulation, polyolefin, closed cell, foam insulation, etc. In some embodiments, insulation contained in zone-control unit 100 complies with an industry standard, such as a standard set by the Office of Statewide Health and Planning Department (OSHPOD).

[0045] For VAV zone-control units 100, the mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com