Method and Apparatus for Tenderizing Meat

a meat and meat technology, applied in the field of meat processing and improving can solve the problems of inability to commercialize meat products, inability to meet the needs of meat processing, so as to achieve the effect of increasing the tenderness of mea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental examples

[0067] B. Experimental Examples

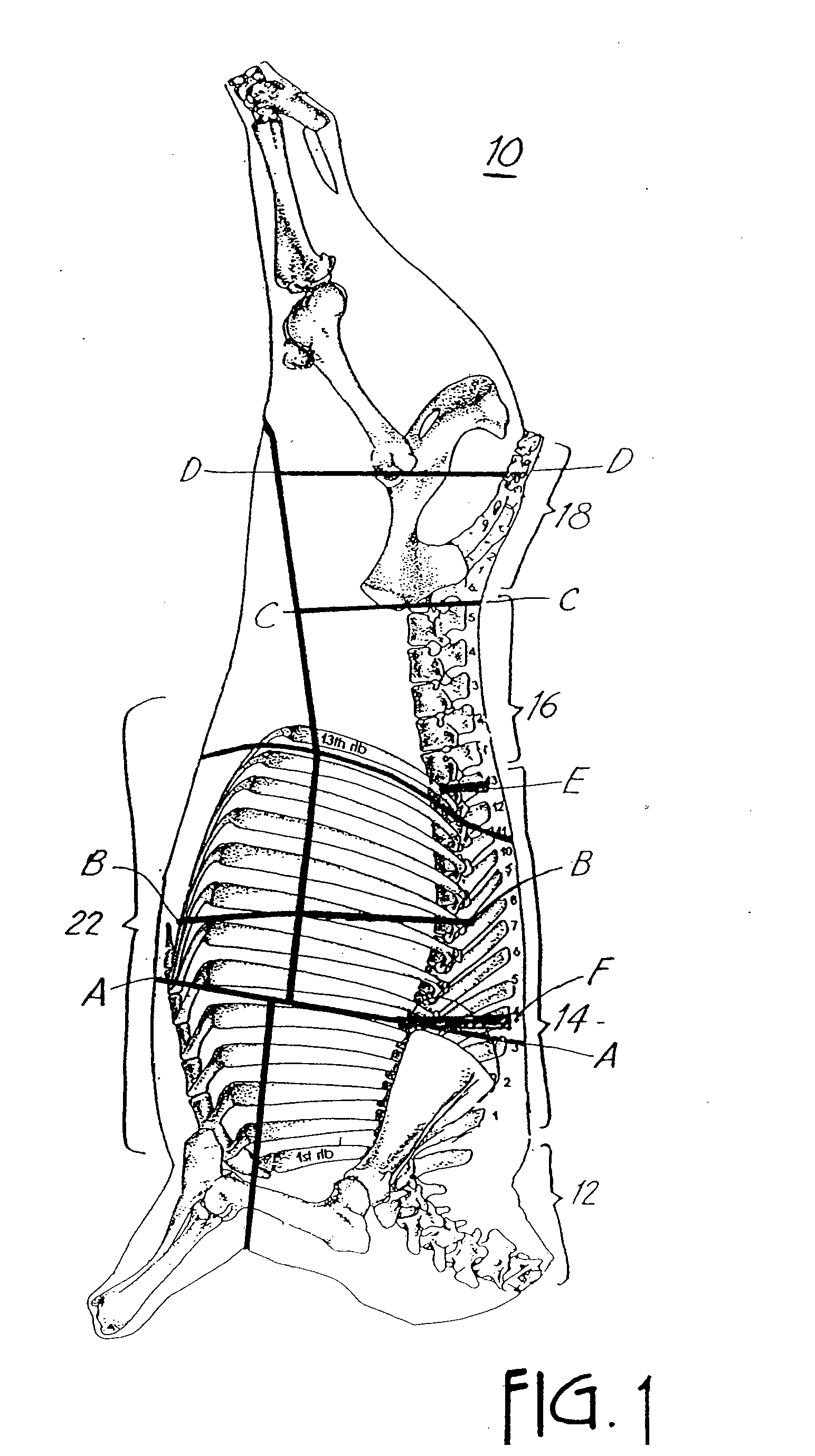

[0068] The applicants discovered the effect of vertebral separation on meat tenderness accidentally during tests to determine the effect of electrical stimulation on meat tenderness. In the electrical stimulation tests, sixty-seven whole carcasses were tested, with sixty-seven sides used as a control group, thirty-two sides being subjected to fifty volts for thirty seconds, and thirty-five sides being subjected to fifty volts for sixty seconds. During the course of the electrical stimulation tests, the incidence and severity of carcasses with broken vertebra or vertebrae was noted. The broken vertebra or vertebrae most likely resulted from hide removal, although the vertebrae or vertebra may have been broken by other means. In reviewing the results of the electrical stimulation tests, the applicants determined that carcasses with broken vertebra or vertebrae produced more tender meat, and hence further testing was done in a controlled setting to determ...

second embodiment

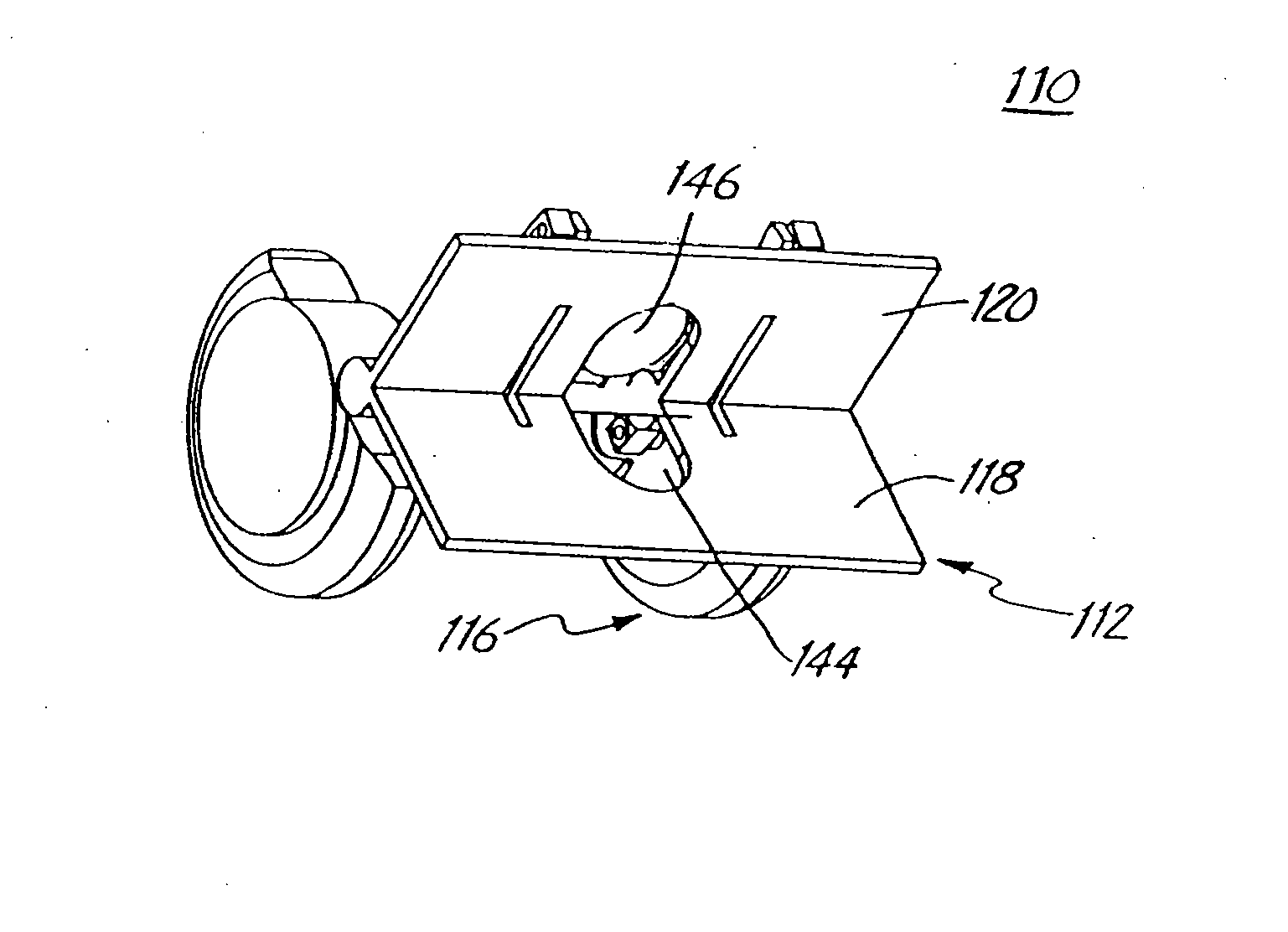

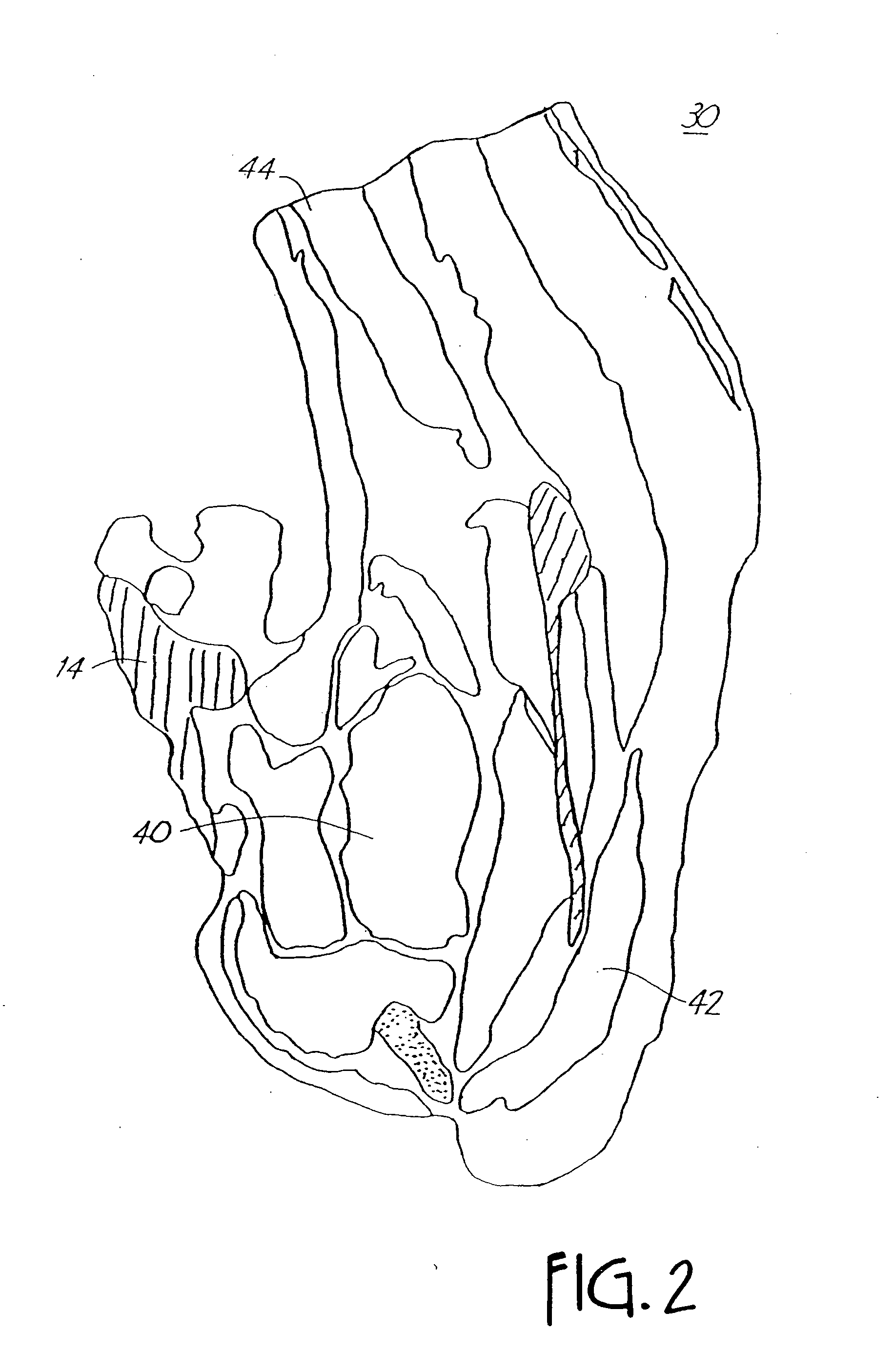

[0078] As may be seen in FIGS. 10-12, which illustrate the apparatus, during operation the plate 112 may be placed against a carcass (a side of beef in FIGS. 10-12) with the lower face plate 118 along the portion of the carcass that was sawed when a whole carcass was split into two sides and the upper face plate 120 along the rib portion of the carcass. Each face plate 118, 120 may vary in size and geometry. In the embodiment depicted in FIGS. 6-9, each face plate 118, 120 is substantially rectangular in shape, and the lower face plate 118 is approximately 4.35 inches wide and ten inches long, while the upper face plate 120 is approximately 3.5 inches wide and ten inches long. Each face plate 118, 120 is about 0.25 inches thick in this embodiment. The plate 112 may be made from any rigid material appropriate for food processing applications, including but not limited to metals and plastics. The system 112 may include a pin, a plurality of pins or posts, an elevated or relieved regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com