Barrel plating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

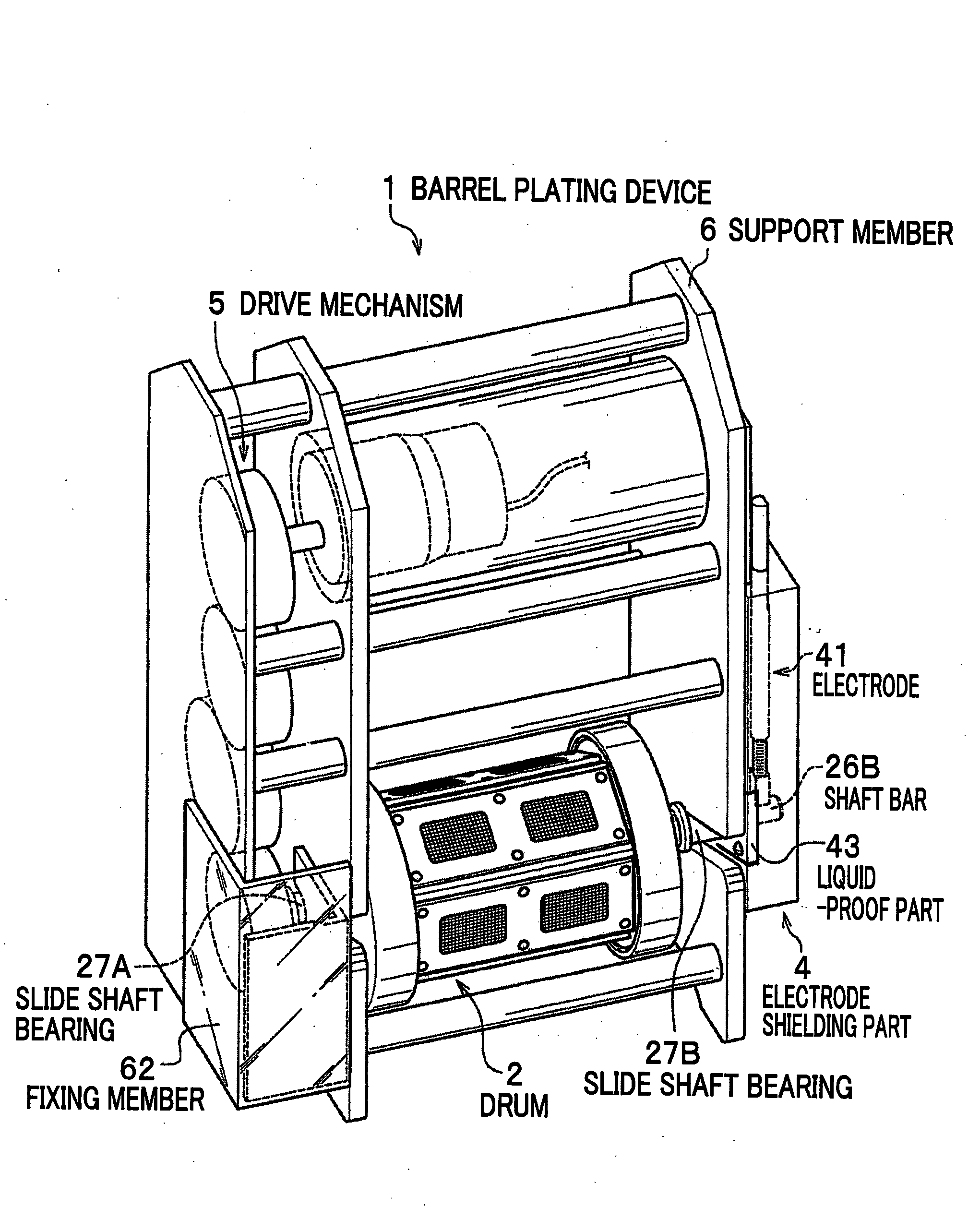

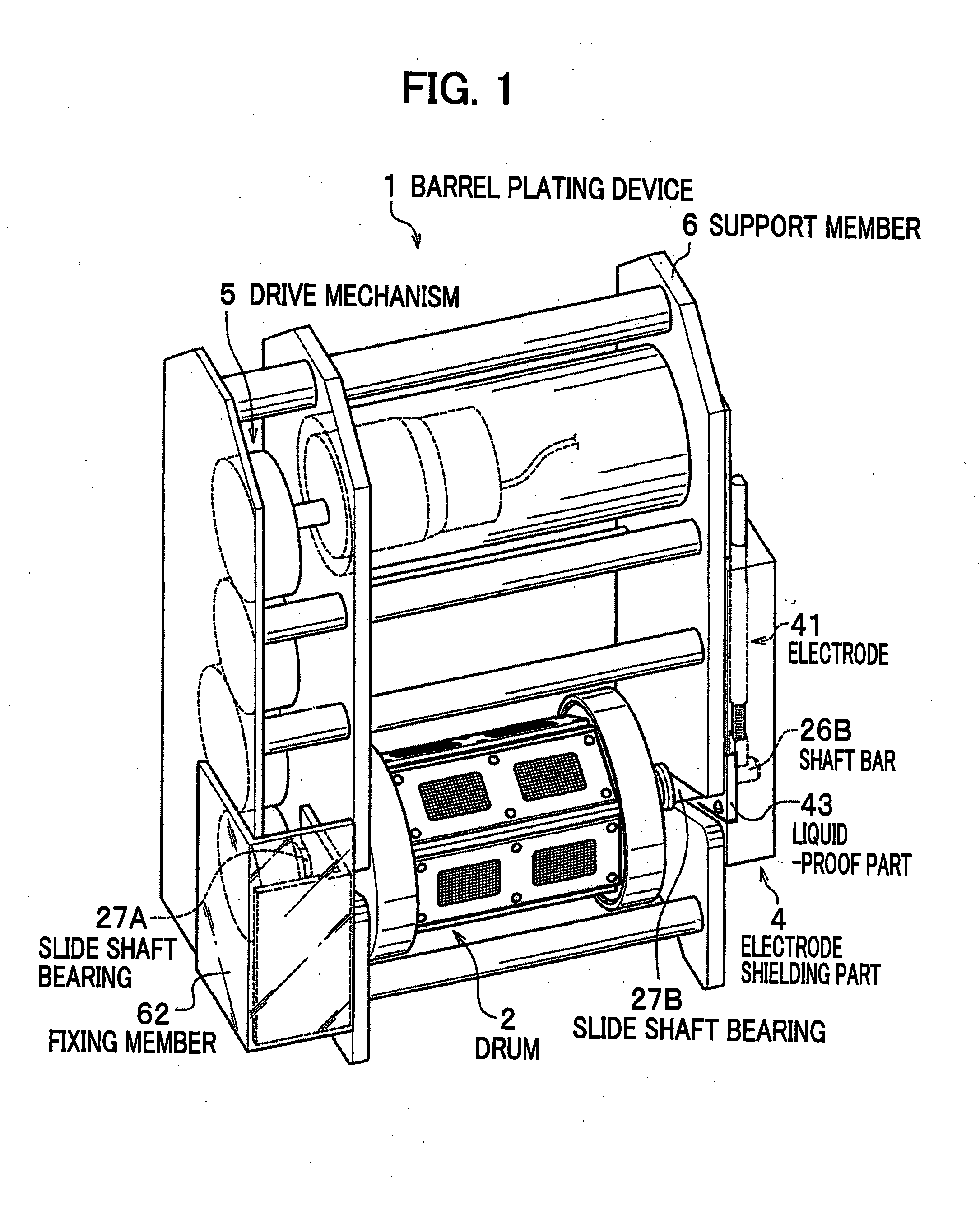

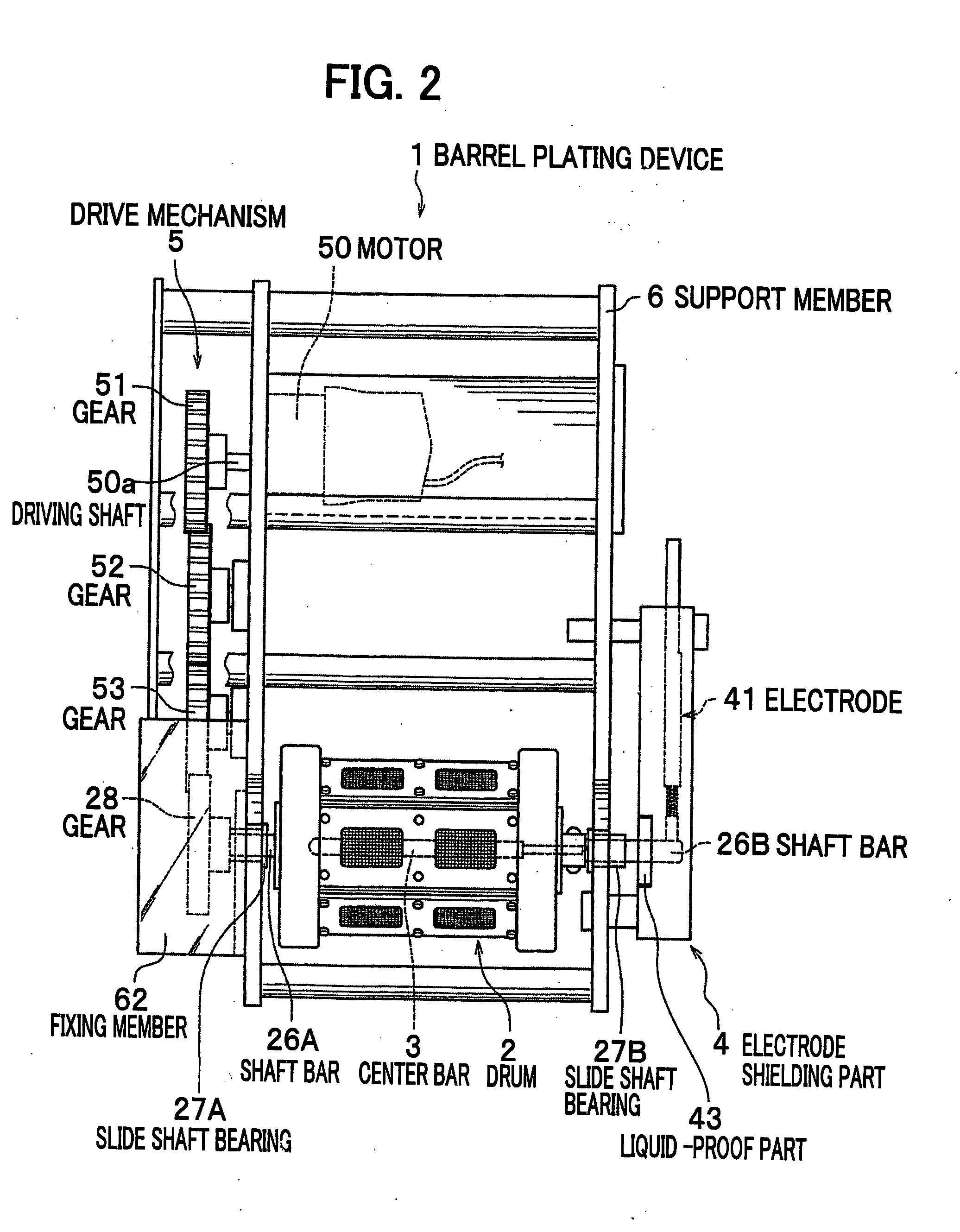

[0042]Embodiments of the present invention will be described in detail below with reference to the drawings.

(Barrel Plating Device 1)

[0043]A barrel plating device 1 according to the present invention is a device for plating small objects, such as small parts, and as shown in FIGS. 1 and 2, is mainly formed of: a drum 2 configured for holding objects to be plated therein; a center bar 3 arranged in the drum 2 coaxially with the drum 2 (see FIG. 2); an electrode shielding part 4 configured for protecting an electrically connected part between a shaft bar 26B and an electrode 41 from a plating solution, to which shaft bar 26B the center bar 3 is connected; a driving mechanism 5 configured for rotatably driving the drum 2 about a center of an axle thereof; and a support member 6 configured for rotatably supporting the drum 2.

[0044]Also referring to FIG. 8, when the barrel plating device 1 is operated, it is immersed in a plating solution L contained in a plating bath 11 in which a posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com