Vibration motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

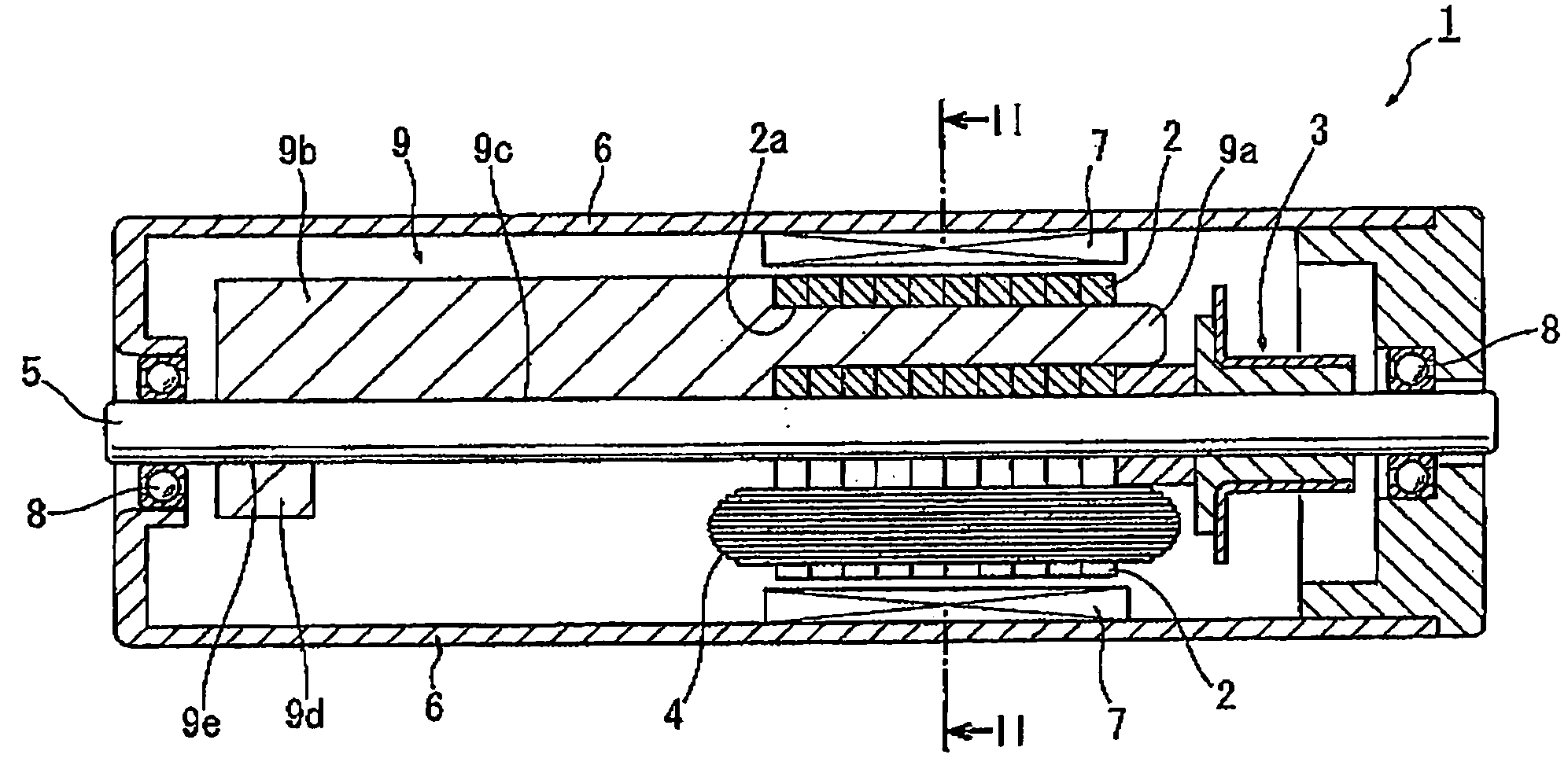

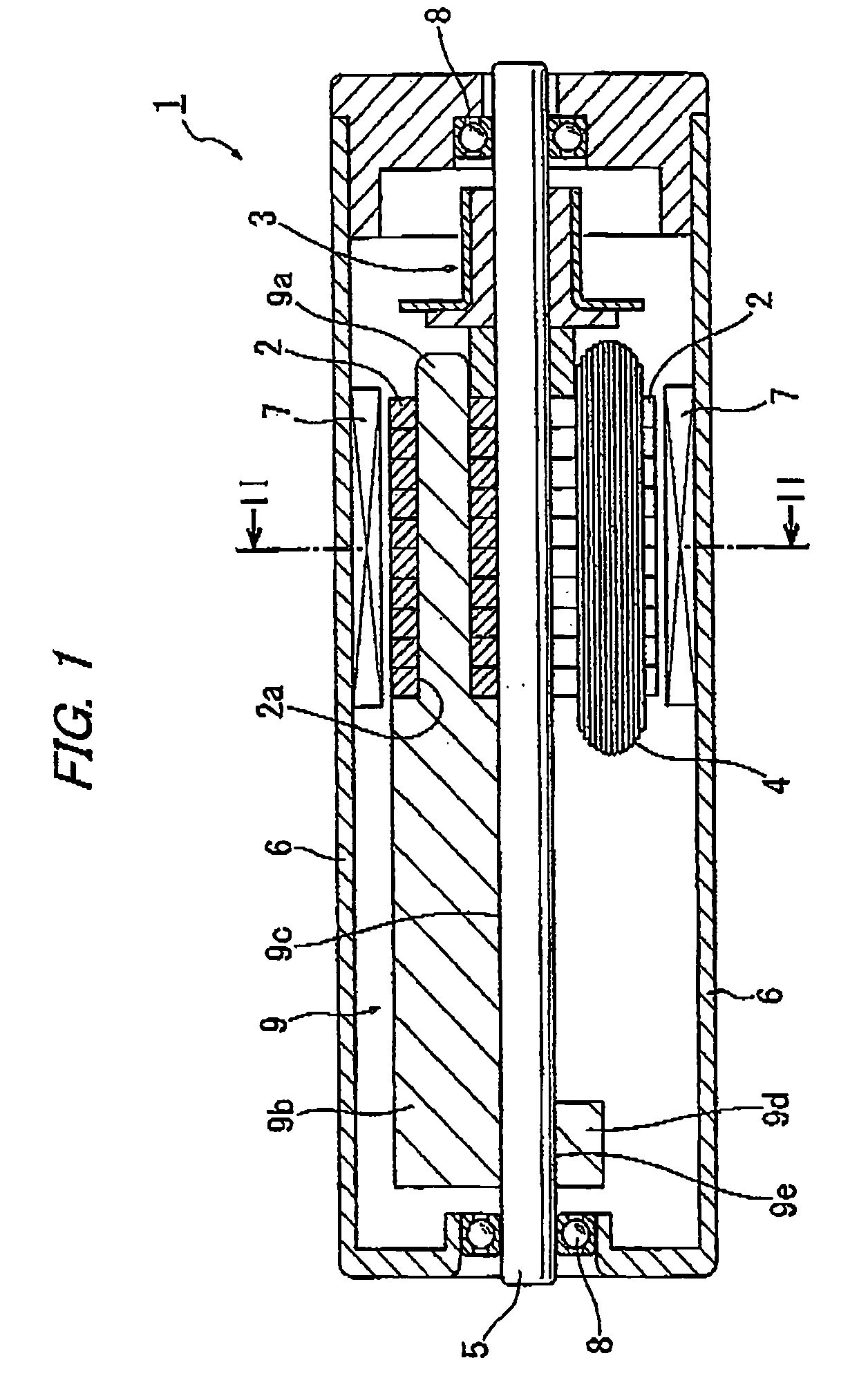

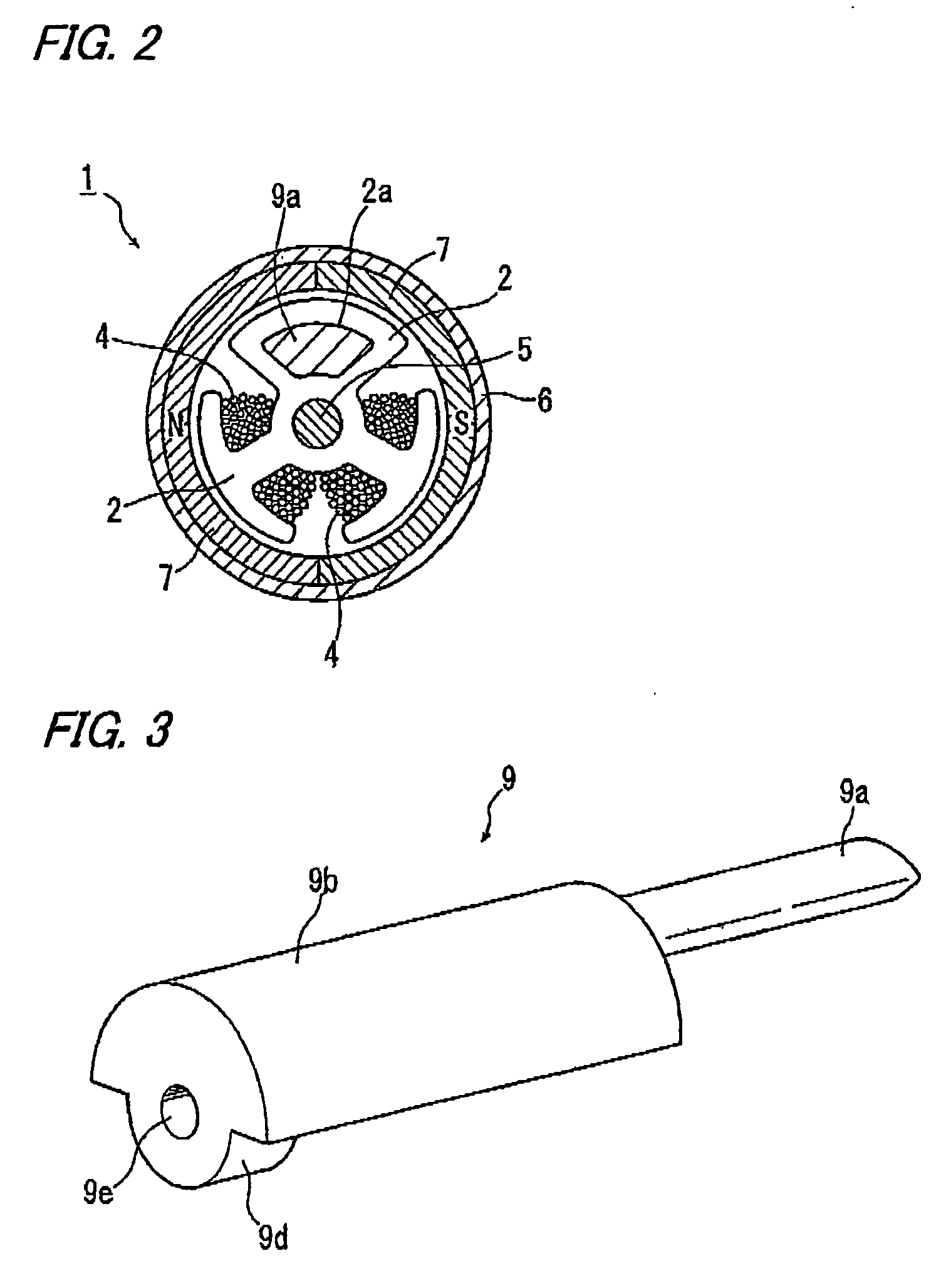

[0043]Now, referring to FIGS. 1 through 6B, description is made about a motor with a commutator as a vibration motor according to a first embodiment of the present invention.

[0044]FIG. 1 is a schematic axial cross-sectional view of the motor with a commutator (hereinafter referred to simply as “motor” as appropriate) 1 according to the first embodiment of the present invention.

[0045]FIG. 2 is a schematic radial cross-sectional view of the motor 1 shown in FIG. 1, taken from line I-I of FIG. 1.

[0046]In the motor 1, a commutator unit 3 and an armature core 2 are mounted on a rotary shaft 5thereby constituting a rotor as a whole. The rotary shaft 5 is detachably disposed and rotatably supported via bearings 8 attached to a frame 6. Magnets 7 are attached to the frame 6 thereby constituting a stator as a whole.

[0047]The armature core 2 is configured such that a required number of magnetic plates each having punched three salient poles are stacked on one another, and only two out of the ...

second embodiment

[0056]Next, referring to FIGS. 7 through 9, description proceeds to a motor with a commutator as a vibration motor according to a second embodiment of the present invention.

[0057]FIG. 7 is a schematic axial cross-sectional view of the motor with a commutator 101 according to the second embodiment of the present invention.

[0058]In the second embodiment, components similar to those of the first embodiment are designated by like reference numerals and their detailed descriptions are omitted accordingly.

[0059]According to the second embodiment, a weight 109 serving as an eccentric weight to vibrate the motor 101 is secured to the rotary shaft 5 not by itself but by means of a weight holding member 112 provided separately from the weight 109.

[0060]FIG. 8 is a perspective view of the weight 109 shown in FIG. 7 seen from above, and FIG. 9 is a perspective view of the weight holding member 112 shown in FIG. 7 seen from below.

[0061]Referring to FIG. 8, the weight 109 includes a semi-cylindri...

third embodiment

[0074]Next, referring to FIGS. 10 through 12, description proceeds to a motor with a commutator as a vibration motor according to a third embodiment of the present invention.

[0075]FIG. 10 is a schematic axial cross-sectional view of the motor with a commutator according to the third embodiment of the present invention.

[0076]In the third embodiment, components similar to those of the first embodiment are designated by like reference numerals and their detailed descriptions are omitted accordingly.

[0077]According to the third embodiment, a weight 209 serving as an eccentric weight to vibrate a motor 201 is secured to the rotary shaft 5 not by itself but by means of a weight holding member 212 provided separately from the weight 209.

[0078]FIG. 11 is a perspective view of the weight 209 shown in FIG. 10 seen from above, and FIG. 12 is a perspective view of the weight holding member 212 shown in FIG. 10 seen from below.

[0079]A material for the weight 209 is determined by giving priority ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com