Beverage dispensing system pressurized release liquid USPA2

a technology of pressurized liquid and beverage containers, which is applied in the field of beverage containers, can solve the problems of unintentional spillage, inconvenient use, and fluid inside the container is prone to surrounding contamination, and achieves the effects of convenient packaging, less physical effort, and increased marketability of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

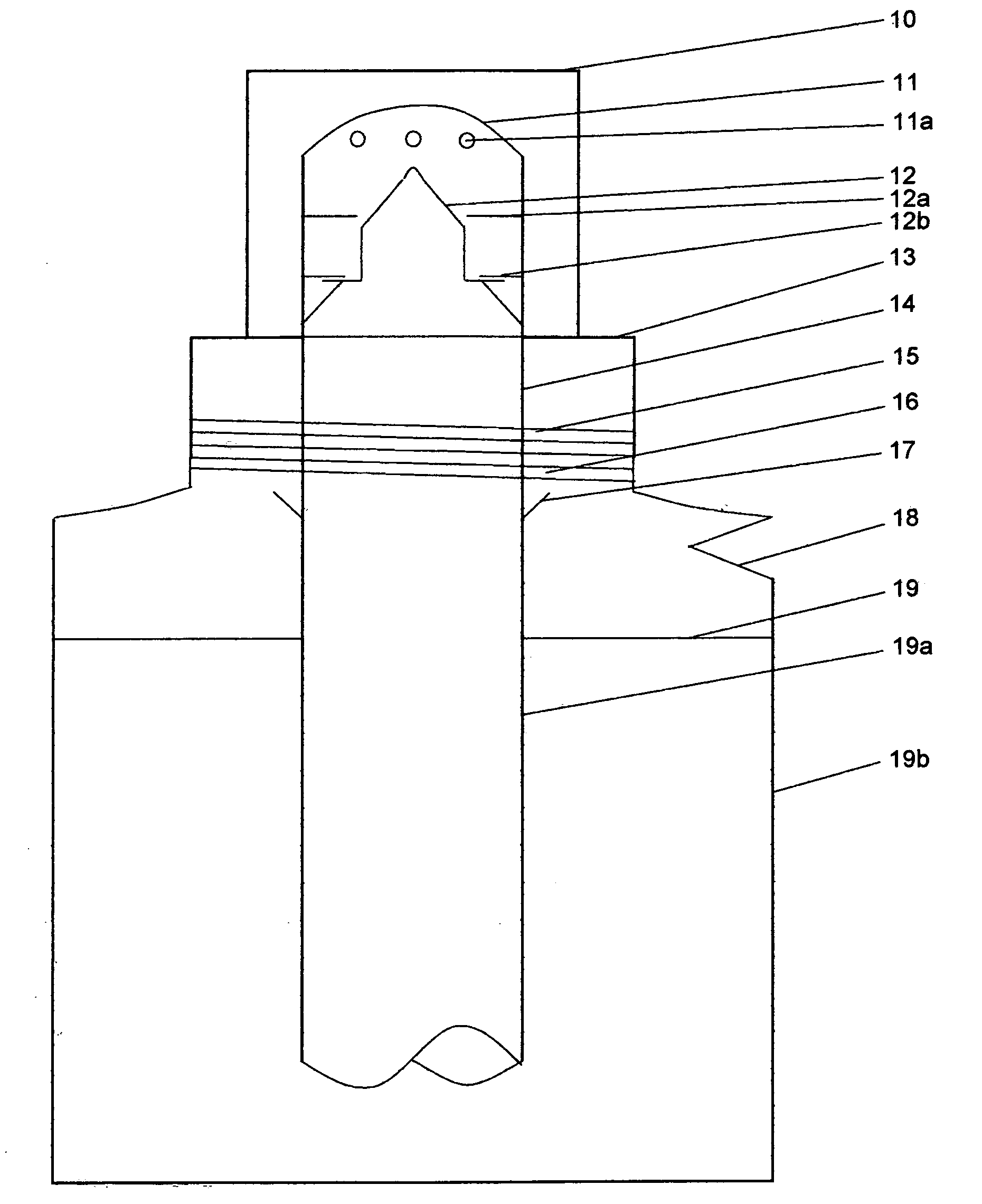

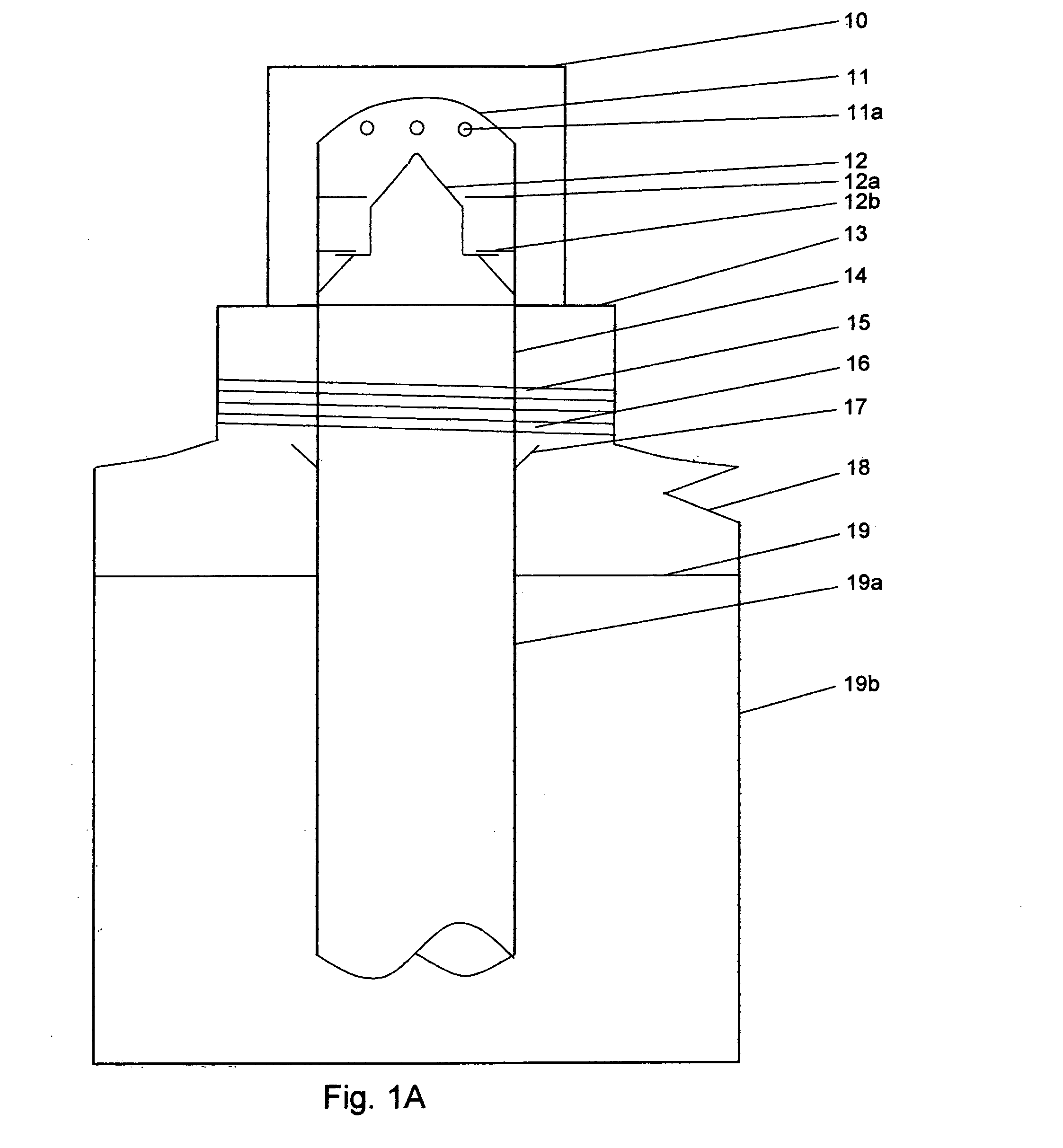

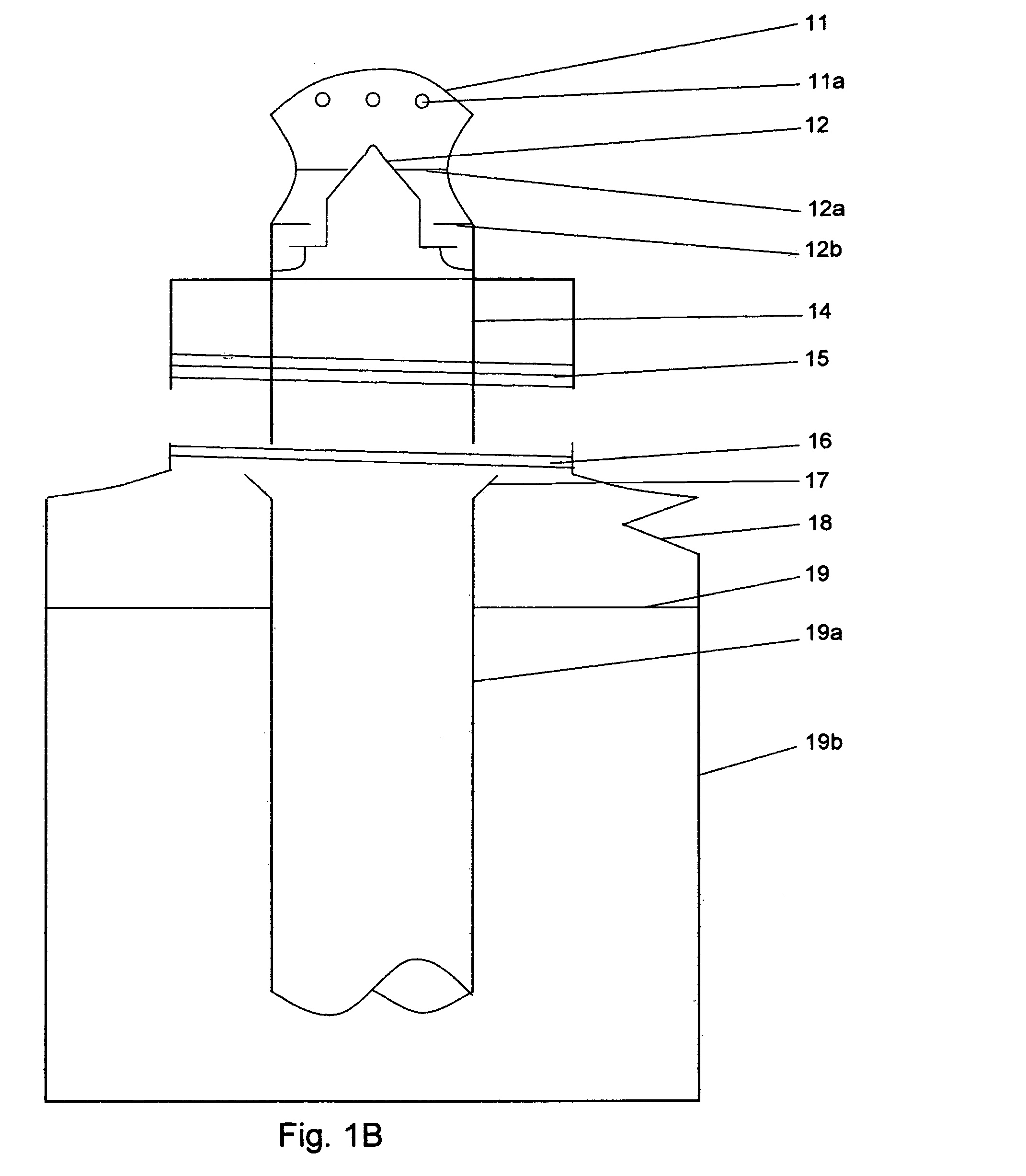

[0224]FIG. 1A shows a front view of a preferred embodiment of the present invention with a nipple cap, the cap screwed on to the container and the valve in the closed position. FIG. 1B shows a front view of the embodiment shown in FIG. 1A with the nipple cap off, the cap screwed off the container and the valve in the open position.

[0225]These figures illustrate a new means of contents regulated in a beverage container and the embodiments to follow will show, replacements of means or parts depicted in this first embodiment and will show add on means or parts that may be added to this first embodiment and certain means or parts depicted in this first embodiment may be removed.

[0226]FIG. 1A shows a cover 10 which is placed on top of the top part of cap tube 14 (nipple) and is removable. The cover 10 protects the nipple from dirt. The top part of the cap tube 14 (nipple) projects thru the top horizontal wall of the cap 13 and the cap tubes 14 walls outer perimeter is attached hermetical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com