Reusable Container and Method for Retorting Flexible Packages Containing Foodstuff

a flexible package and container technology, applied in packaging, biochemistry apparatus and processes, beer brewing, etc., can solve the problems of large capital investment, large cost of continuous retort system, so as to reduce packaging cost, reduce cost, and thoroughly heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

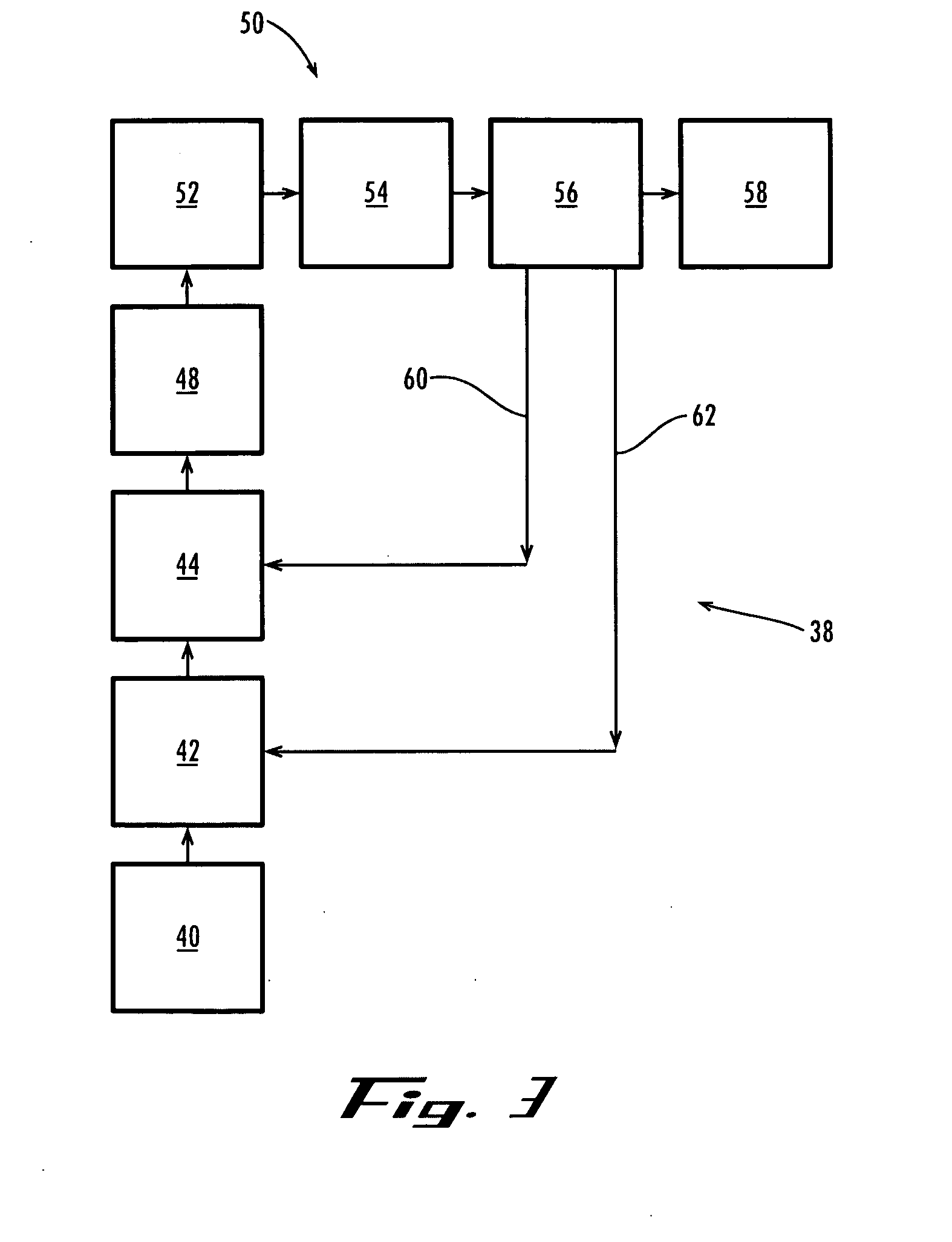

[0017] As summarized above, this invention encompasses a method for retorting flexible packages containing foodstuff and a reusable, hermetically resealable, rigid retort container for retorting flexible packages containing foodstuff. Embodiments of the method and container of this invention are described in detail below. An embodiment of this invention is particularly useful for retrofitting existing conventional continuous retort systems normally configured for retorting canned foodstuff such that the same system can be used to retort foodstuff packaged in flexible packages such as flexible pouches. Such an embodiment provides a relatively inexpensive method of retorting foodstuff packaged in flexible packages because a custom reconfiguration of the retort system or the purchase of a new custom retort system for flexible packaging is avoided.

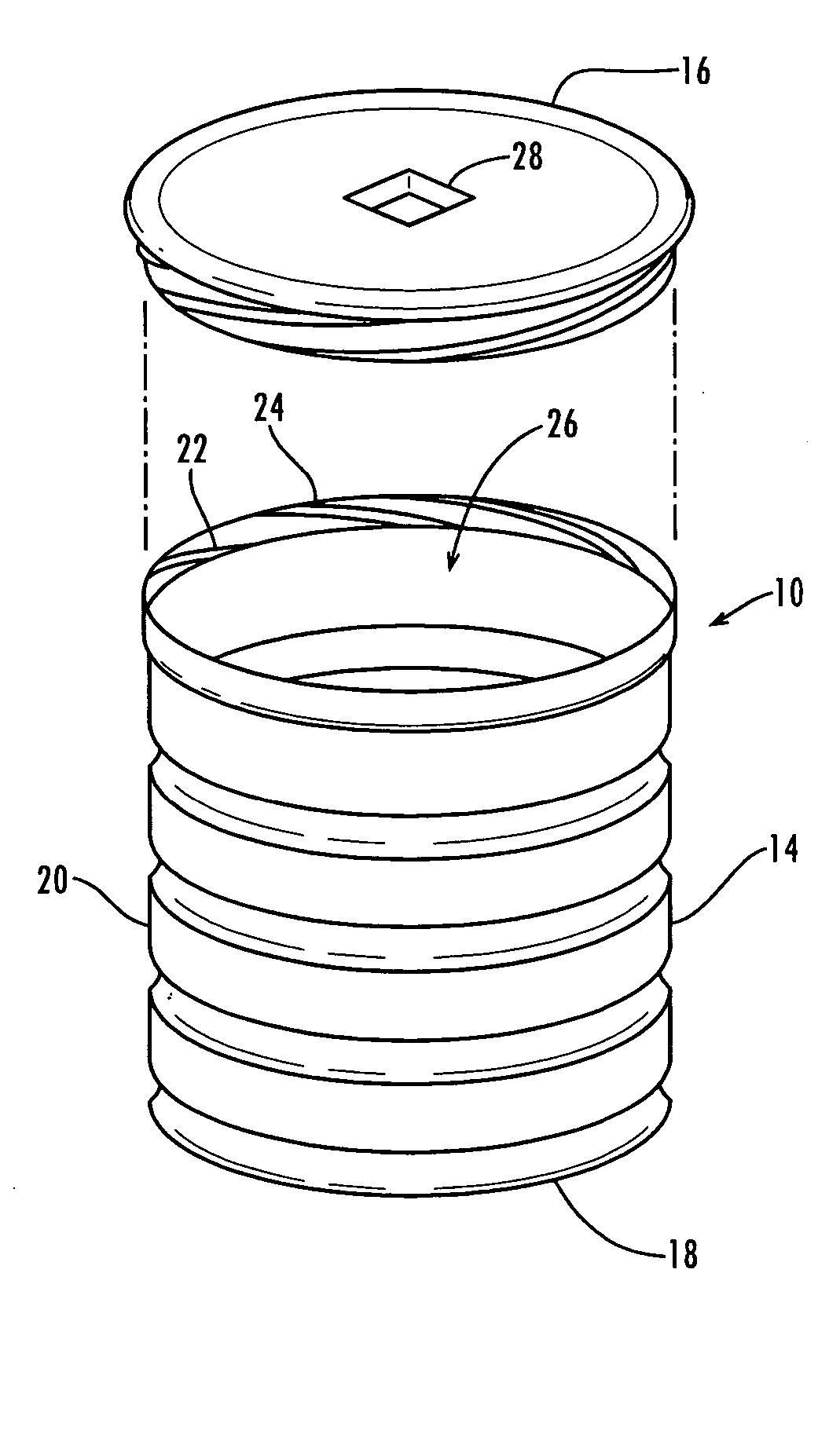

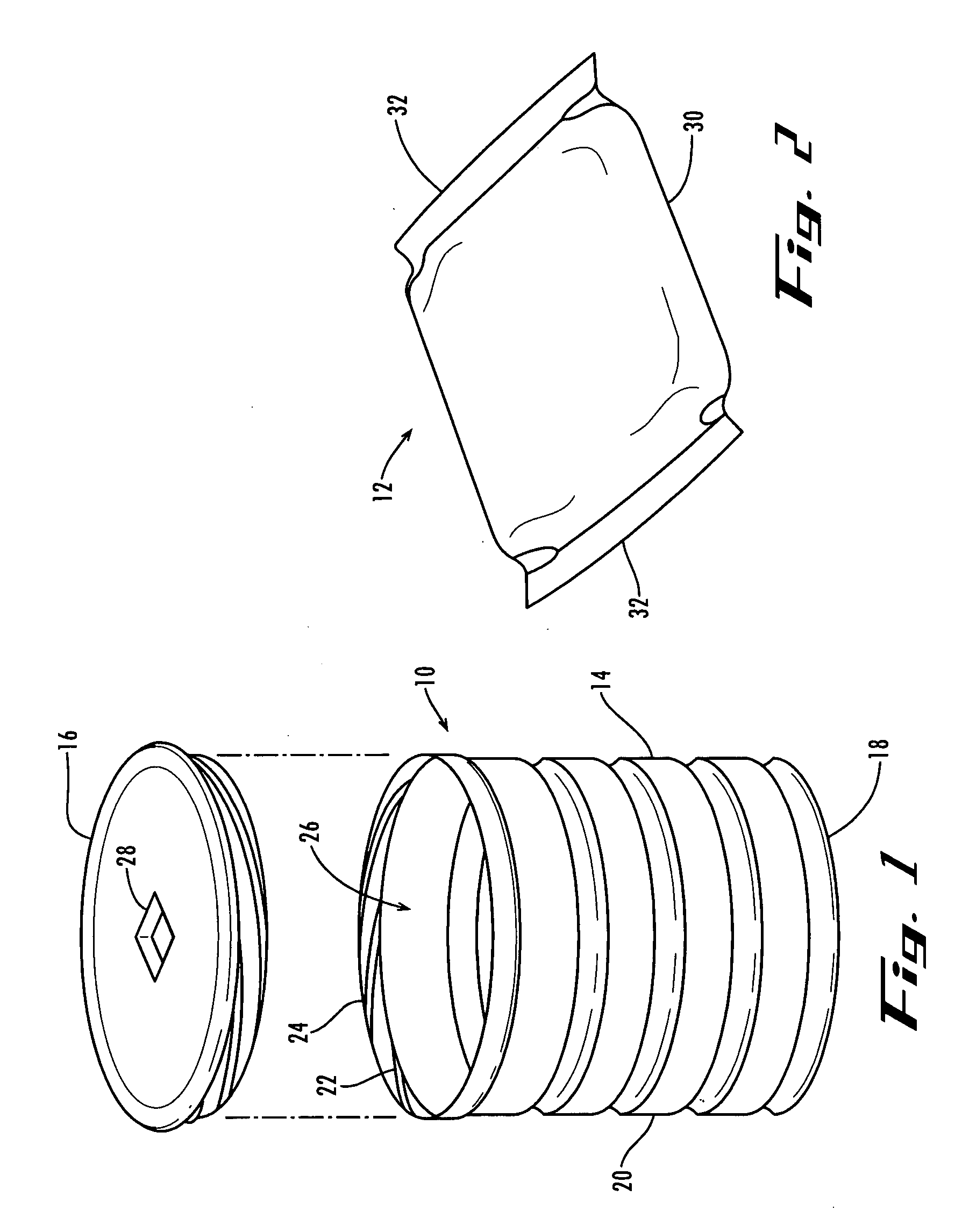

[0018] Turning to FIGS. 1 and 2, a retort container 10 and a flexible pouch filled with foodstuff in accordance with an embodiment of this i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com