Waste hot wind circulating device

A technology of hot air circulation and heating chamber, applied in heating devices, lighting and heating equipment, dryers, etc., can solve the problems of waste of energy, waste of waste hot air and heat energy, and increase of energy consumption of enterprises.

Inactive Publication Date: 2015-09-23

遵义市郎笑笑食品有限责任公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, many manufacturers usually discharge the waste hot air directly into the air after drying the hot air, instead of recycling the waste hot air; Enterprise energy consumption, wasted energy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

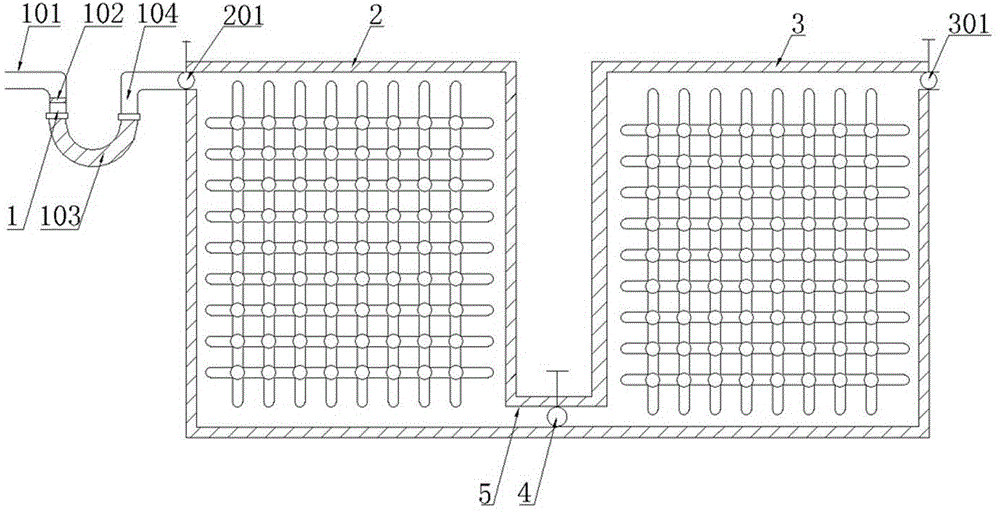

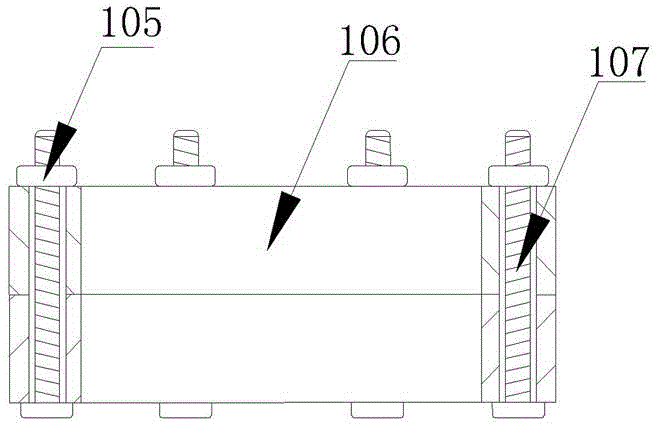

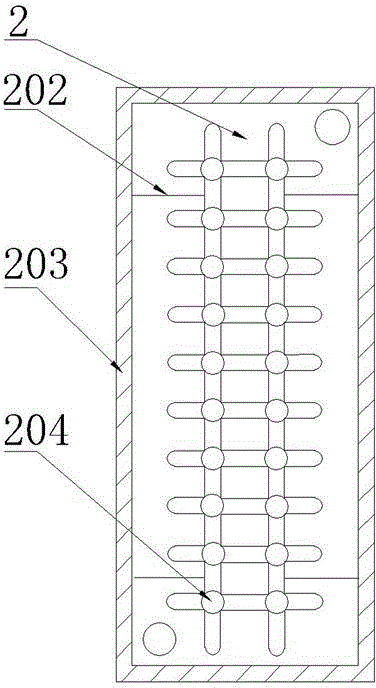

The invention discloses a waste hot wind circulating device in the field of drug processing equipment. The device comprises a heating chamber. The heating chamber is internally provided with a heater. A thermal-insulating layer is connected with the external of the heating chamber. The device also comprises an integrated pipeline, a straight pipe, and a thermal-insulating chamber. The integrated pipeline is on the air inlet of the heating chamber. The straight pipe is between the heating chamber and the thermal-insulating chamber. The integrated pipeline comprises a blast pipe, a U-shaped pipe, and a discharge pipe. The blast pipe is on the air inlet end of the U-shaped pipe. The discharge pipe is on the air outlet end of the U-shaped pipe. The thermal-insulating chamber is internally provided with a warmer. The external of the thermal-insulating chamber is provided with a thermal-insulating layer. Through implementing the device, problems in the prior art that after hot wind dries honeysuckle flowers, generated waste hot wind cannot be recycled, which cause energy and environmental loss are solved, and a problem of storage after waste hot wind is recycled and heated is also solved.

Description

technical field [0001] The invention relates to the field of medicinal material processing equipment, in particular to a waste hot air circulation device. Background technique [0002] Honeysuckle is the collective name of Chinese medicinal materials and plants, also known as honeysuckle, is a perennial, semi-evergreen, intertwined woody vine, and is famous for its extensive medicinal value. Heat toxin blood dysentery, carbuncle furuncle and so on. [0003] At present, in the use and preservation of honeysuckle, it is dried honeysuckle; therefore, the drying process is the most important part of the process of changing honeysuckle from fresh flowers to dried flowers; because the effect of hot air drying honeysuckle is good, and drying The quality of the later honeysuckle is also very good; therefore, most honeysuckle manufacturers use hot air to dry fresh honeysuckle to obtain dried flowers. However, many manufacturers usually discharge the waste hot air produced by hot ai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F26B23/10

Inventor 李兵

Owner 遵义市郎笑笑食品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com