Diaphragm pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

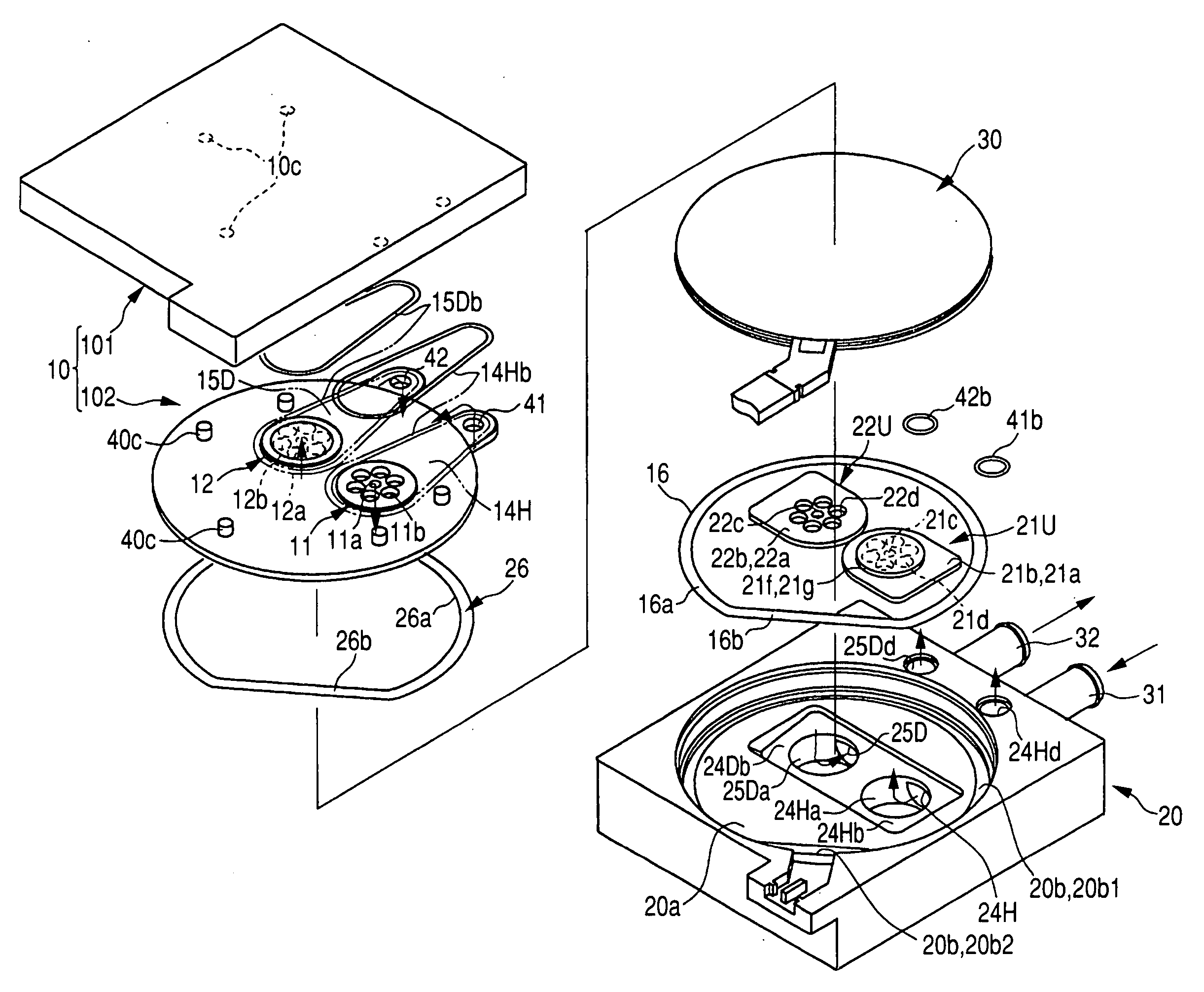

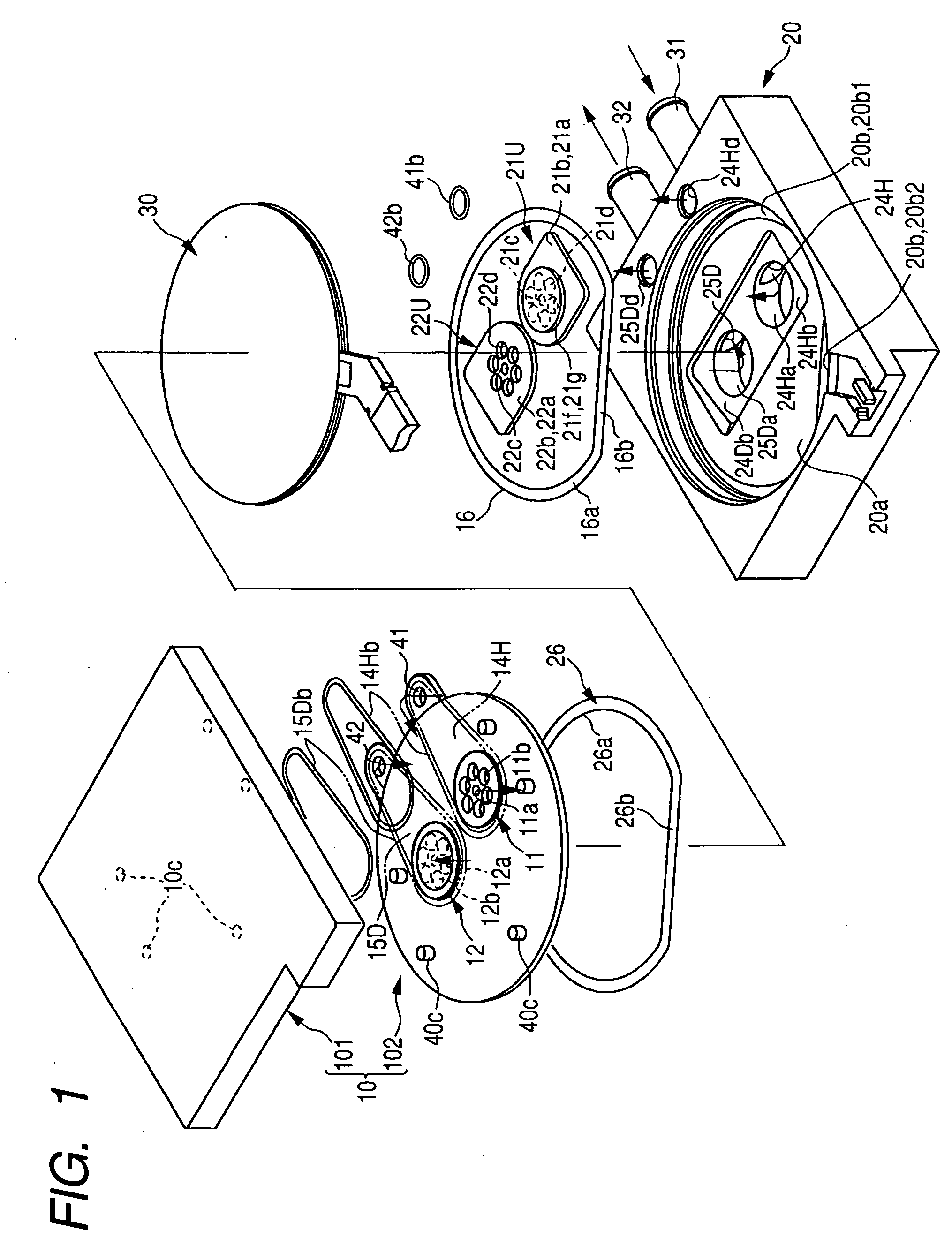

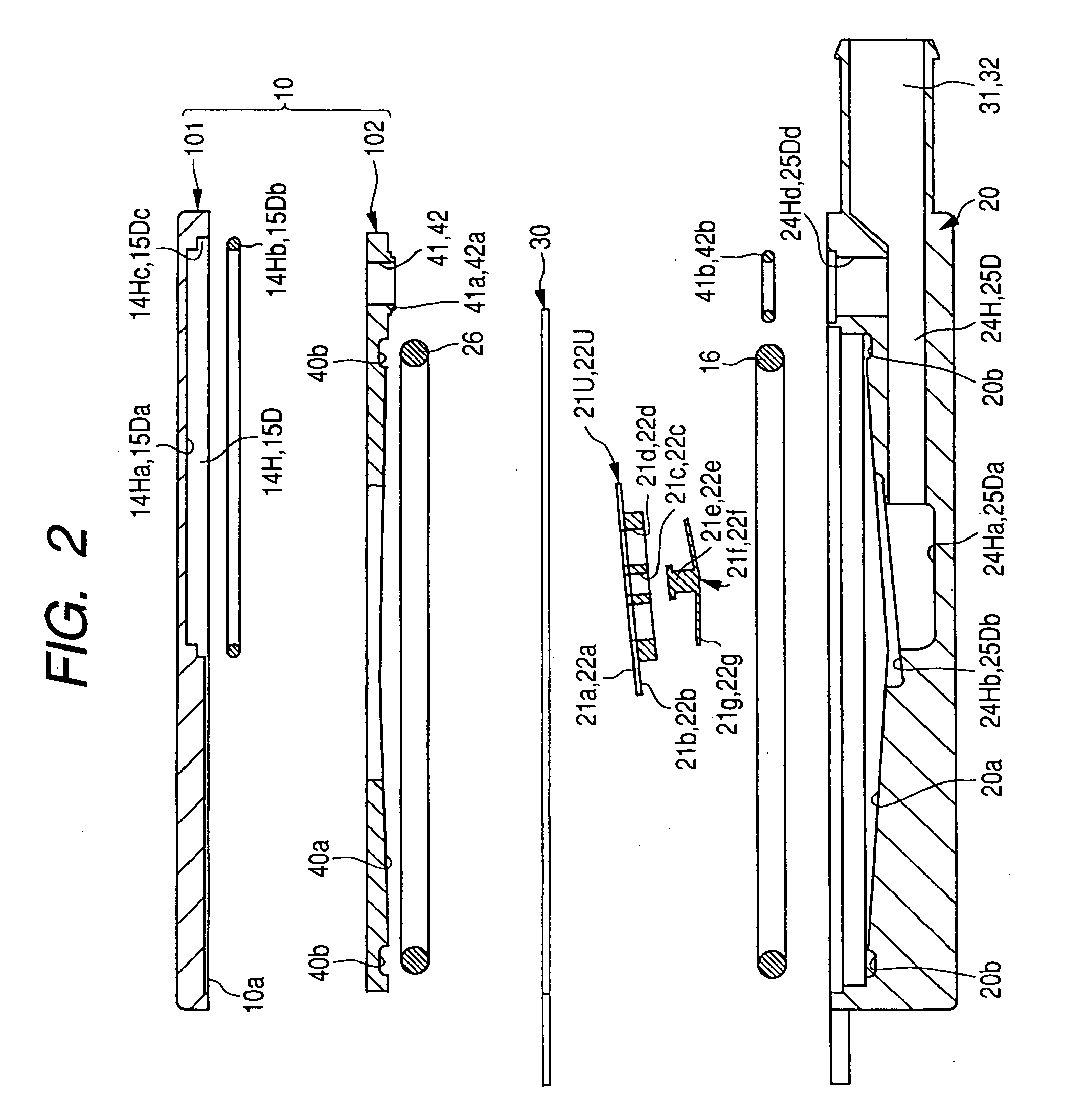

[0033] Illustrated embodiments are obtained by applying the present embodiments to a 4-valve diaphragm pump that the present applicant proposed the principle in Japanese Patent Application No. 2004-154991. One embodiment thereof will be described with reference to FIGS. 1 to 7. In one exemplary embodiment, the diaphragm pump has an upper housing 10, a lower housing 20, and a piezoelectric vibrator 30, and is in the shape of a flat rectangular parallelepiped as a whole. The upper housing 10 is composed of a blind plate 101 and a pump chamber plate 102, and all the blind plate 101, the pump chamber plate 102, and the lower housing 20 are molded articles made of a resin material.

[0034] The lower housing 20 is a member in the shape of a flat rectangular parallelepiped, which is most large-sized and has a complicate shape, among the molded articles. In the lower housing, a recessed part 20a for forming a pump chamber is formed so as to be open to the side opposing the piezoelectric vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com