Retractable greenhouse

a greenhouse and retractable technology, applied in the field of retractable greenhouses, can solve the problems of increasing the price of non-damaged commodities, destroying the ready to pick strawberries, blackberries and raspberries, and the cost of retractable greenhouses is approximately 10-20% of the cost of permanent structures, so as to achieve the effect of increasing photosynthesis or spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

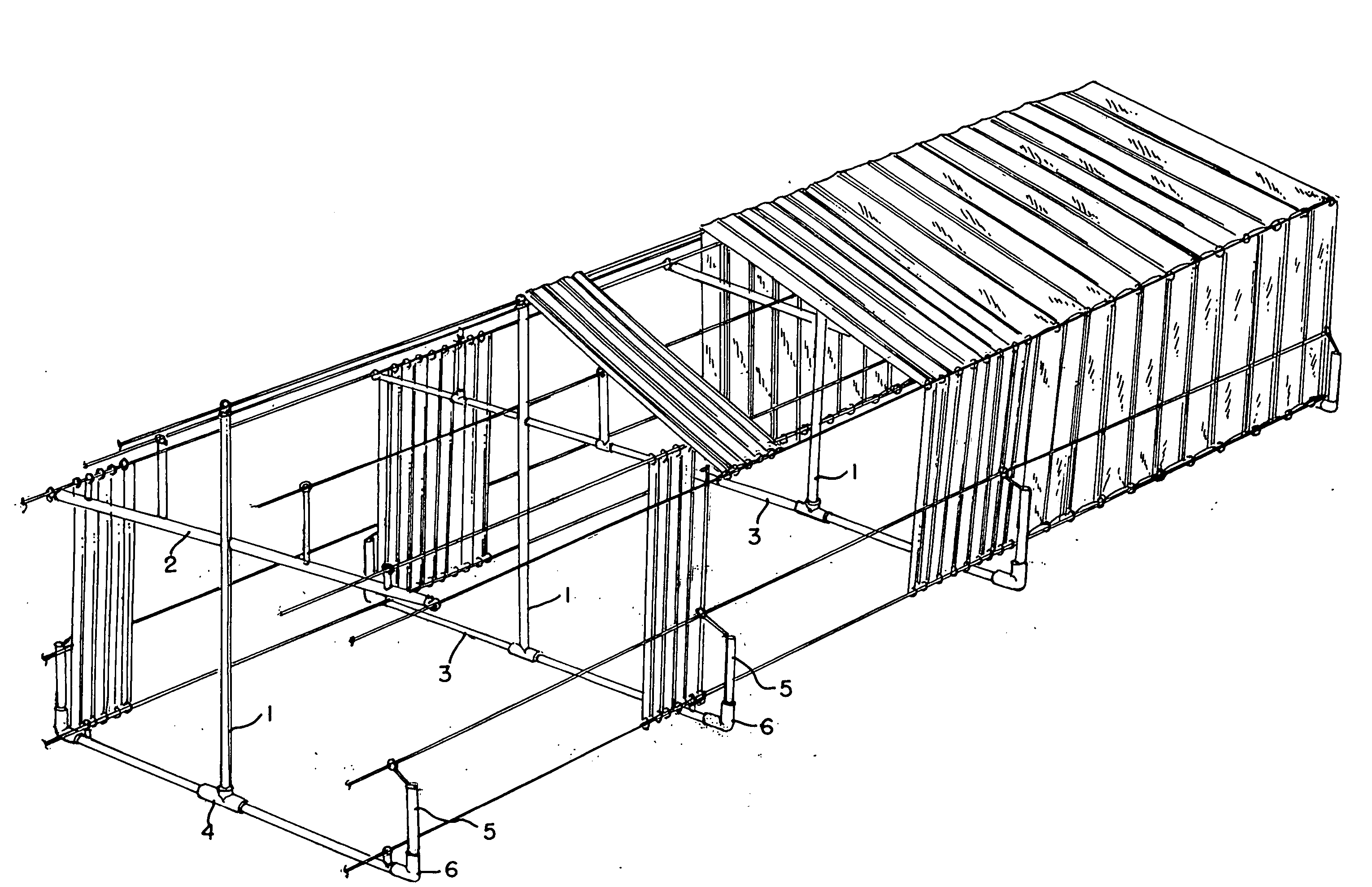

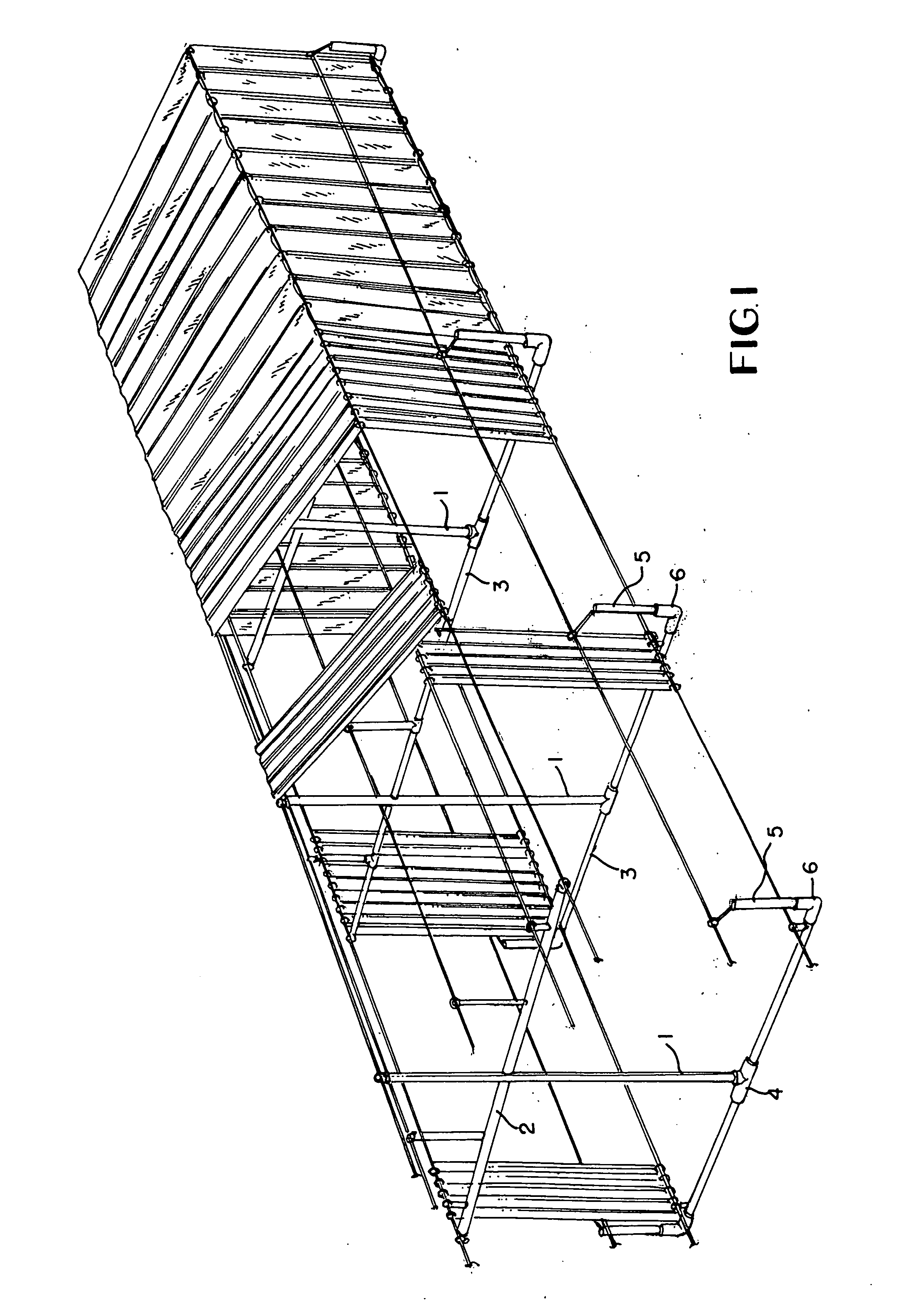

[0030] In the drawings and with particular reference to FIG. 1, the framework for the greenhouse is shown in the form of multiple vertical posts 1, upper horizontal arms 2 and lower horizontal arms 3. Lower horizontal arms 3 are attached to vertical posts 1 by means of couplers 4. In addition, supplementary outer vertical posts 5 extend upwardly from the outer ends of lower horizontal arms 3 and are attached by means of angular couplers 6 to facilitate removal of the exoskeleton component during certain horticultural procedures. Similar inner vertical posts (not shown) can also be utilized with a corresponding inner stabilizing wire.

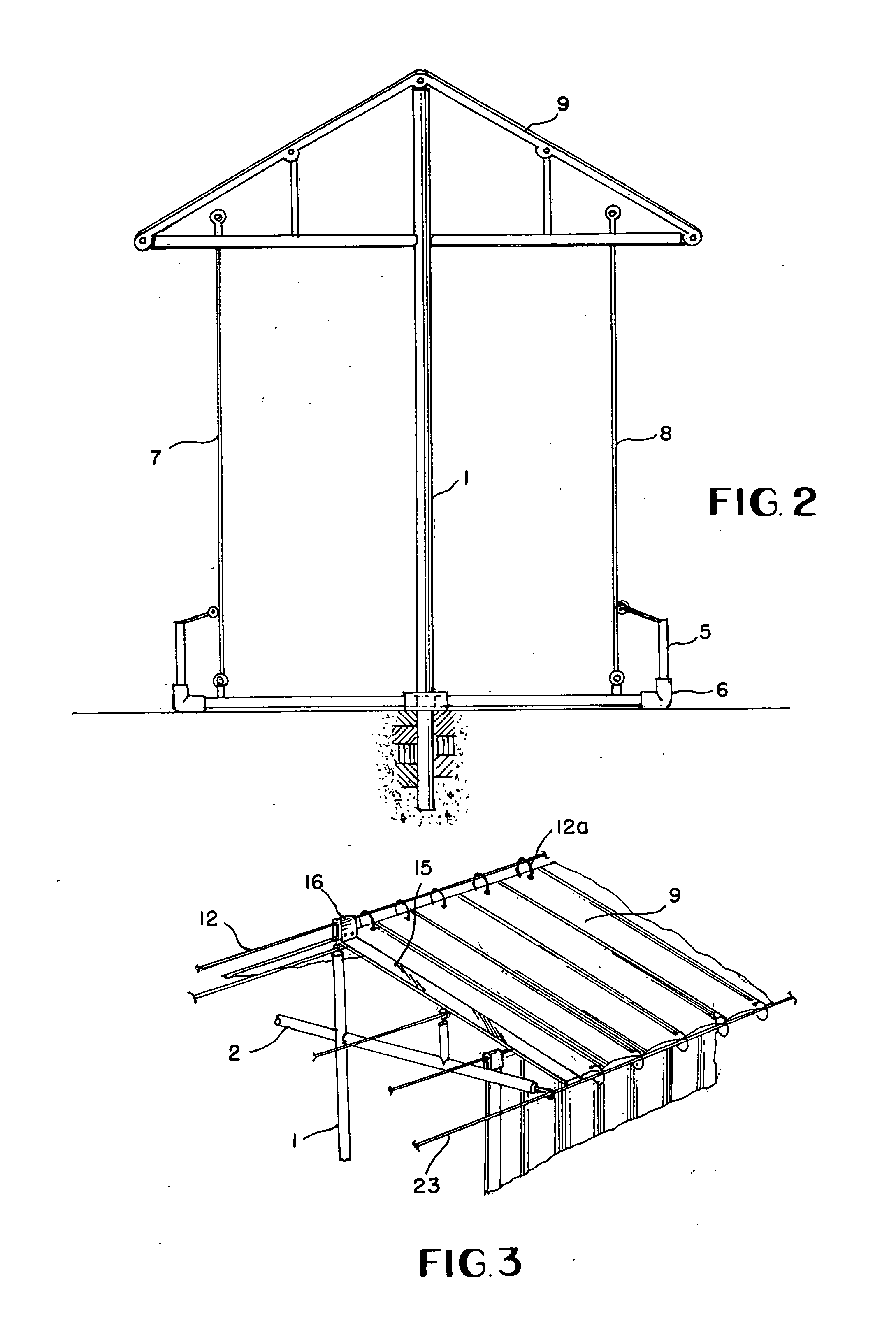

[0031] As best viewed in FIG. 4, the operating system for the greenhouse for the purpose of moving side covers 7 and 8 and roof cover 9 is shown. Each of the side covers 7 and 8 comprises multiple individual panels each one of which extends between adjacent horizontal arms 2 and 3. Similarly, roof cover 9 comprises multiple individual inverted V-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com