Moldable threaded closure configured to receive a common household item to facilitate untightening of the closure

a threaded closure and common household item technology, applied in the field of moldable threaded closures, can solve the problems of difficult untightening of such closures, reduced hand strength and dexterity of persons with reduced hand strength and dexterity, and difficult removal of closures, etc., to facilitate untightening and retightening, facilitate untightening, and mold easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

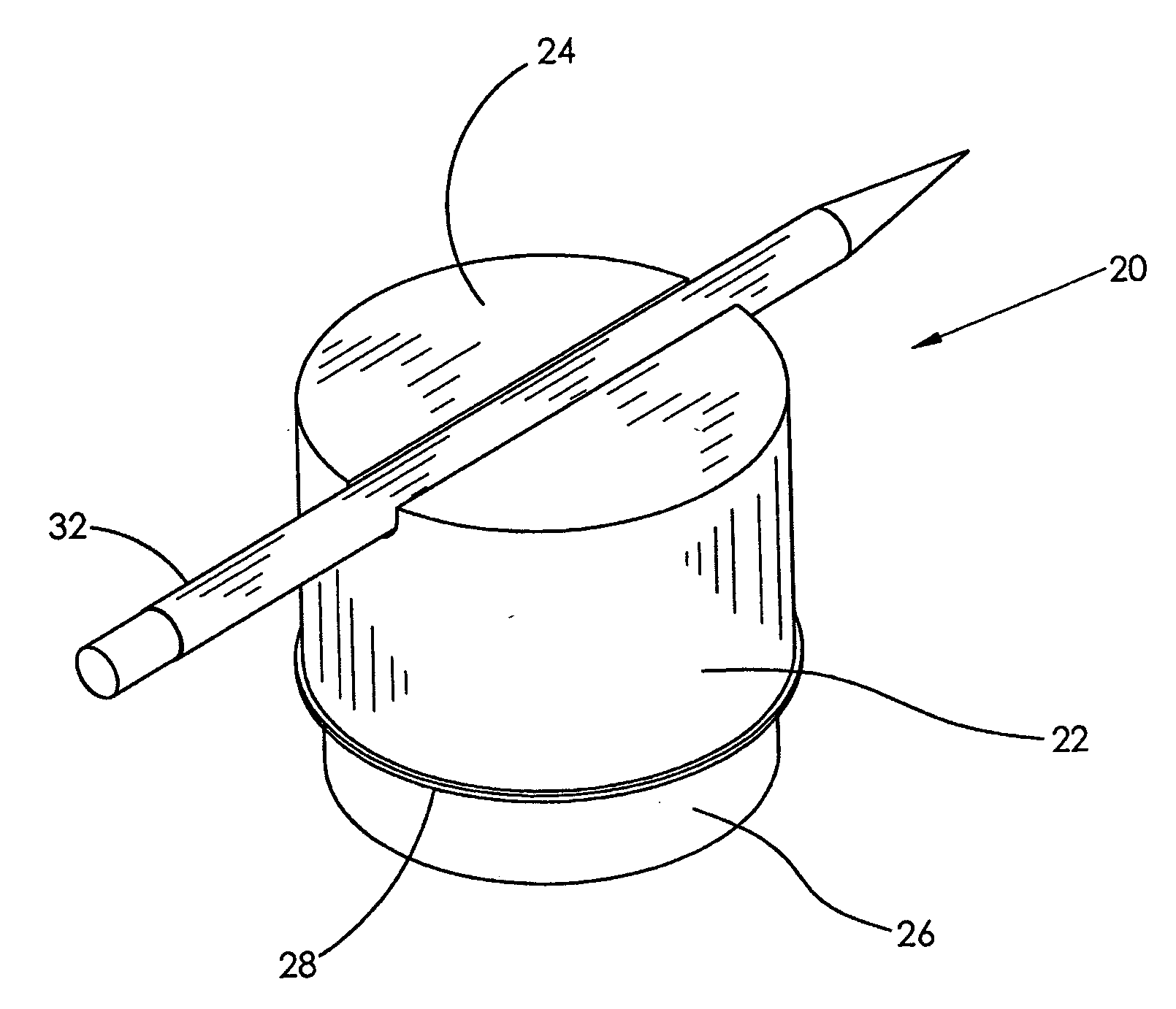

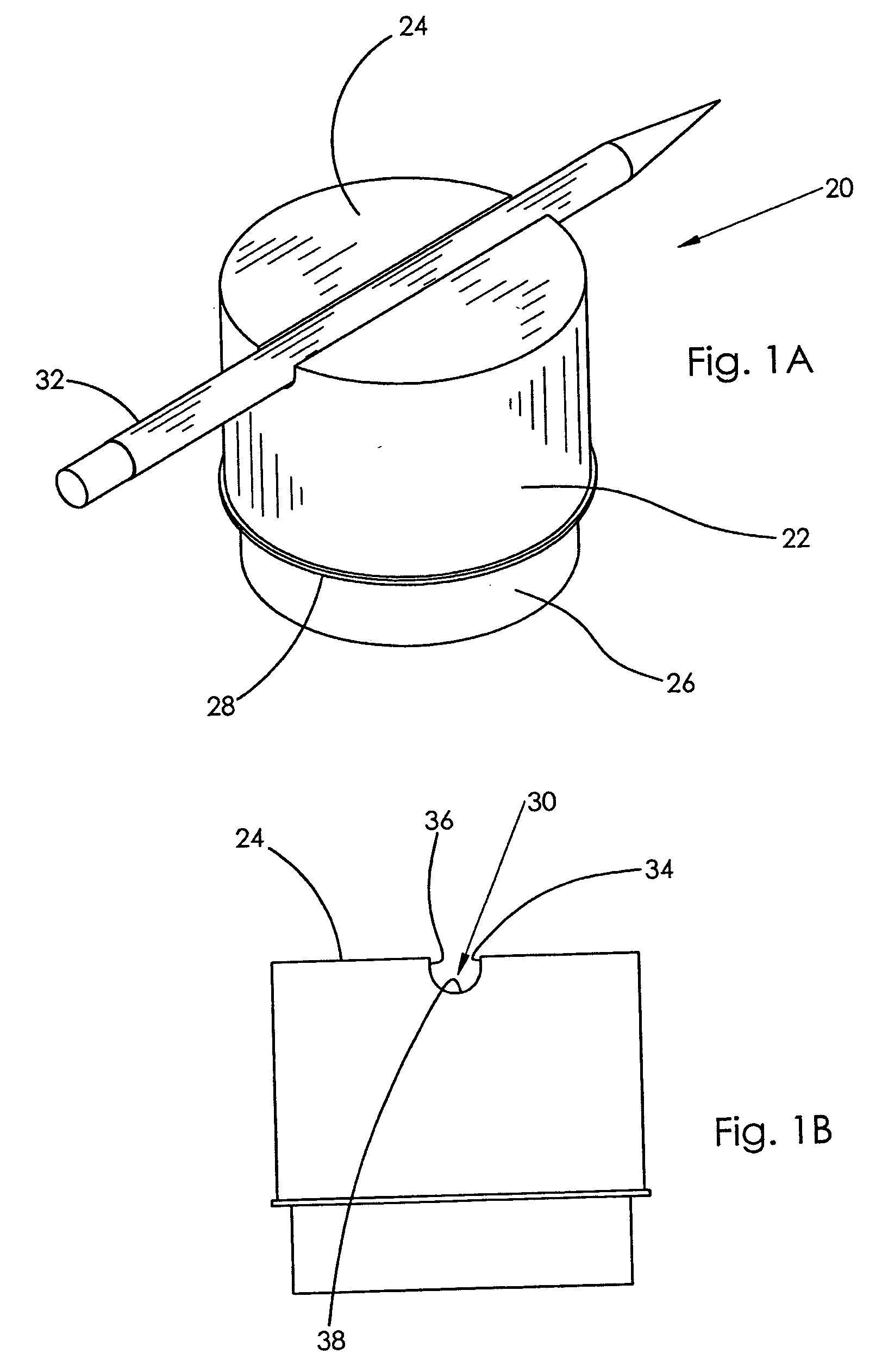

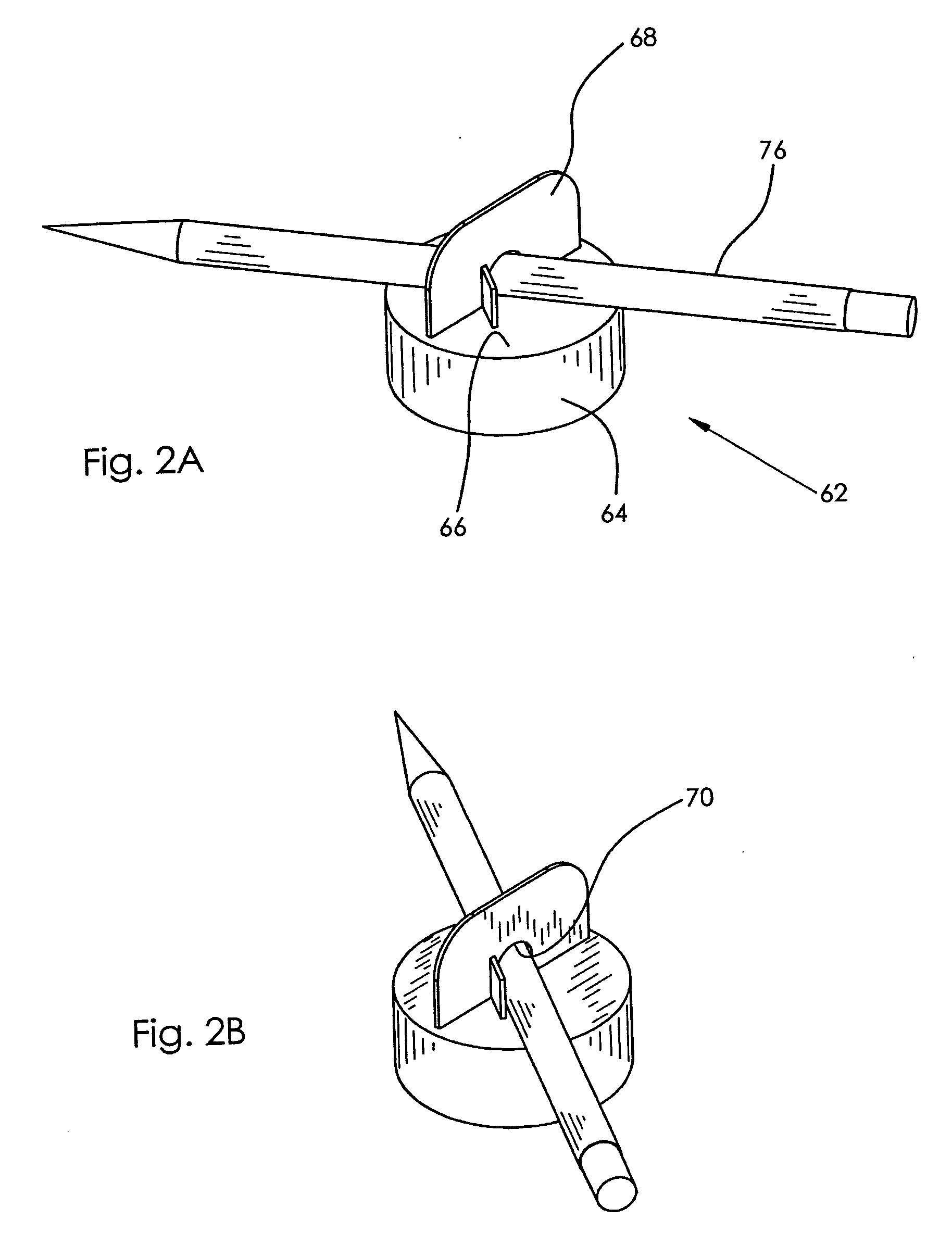

[0022] The present invention relates to a closure system which facilitates untightening and retightening of threaded closures used to close threaded containers. In accordance with an important aspect of the invention, the closure is formed with a receptacle that does not extend beyond the plane of a top surface of the closure. The receptacle is configured to receive common household items, such as pencils for leverage. Various embodiments of the invention are contemplated. In one embodiment, as illustrated in FIGS. 1A1B and 3, a receptacle is formed in the top surface of the closure. Since the receptacle does not extend beyond the plane of the top surface of the closure, containers closed with such closures can be stacked on top of each other on store shelves. Also, such receptacles will not cause any problems with known automated capping machines used to automatically place caps on containers and tighten them. FIG. 4 illustrates another alternate embodiment in which the receptacle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com