Moisture control system

a technology of moisture control and system, applied in the direction of building components, construction, building construction, etc., can solve the problems of moisture intrusion, contributing to possible condensation, and affecting the flow of water, so as to reduce the amount of mold growth, mildew growth, rot and/or pests, and facilitate the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

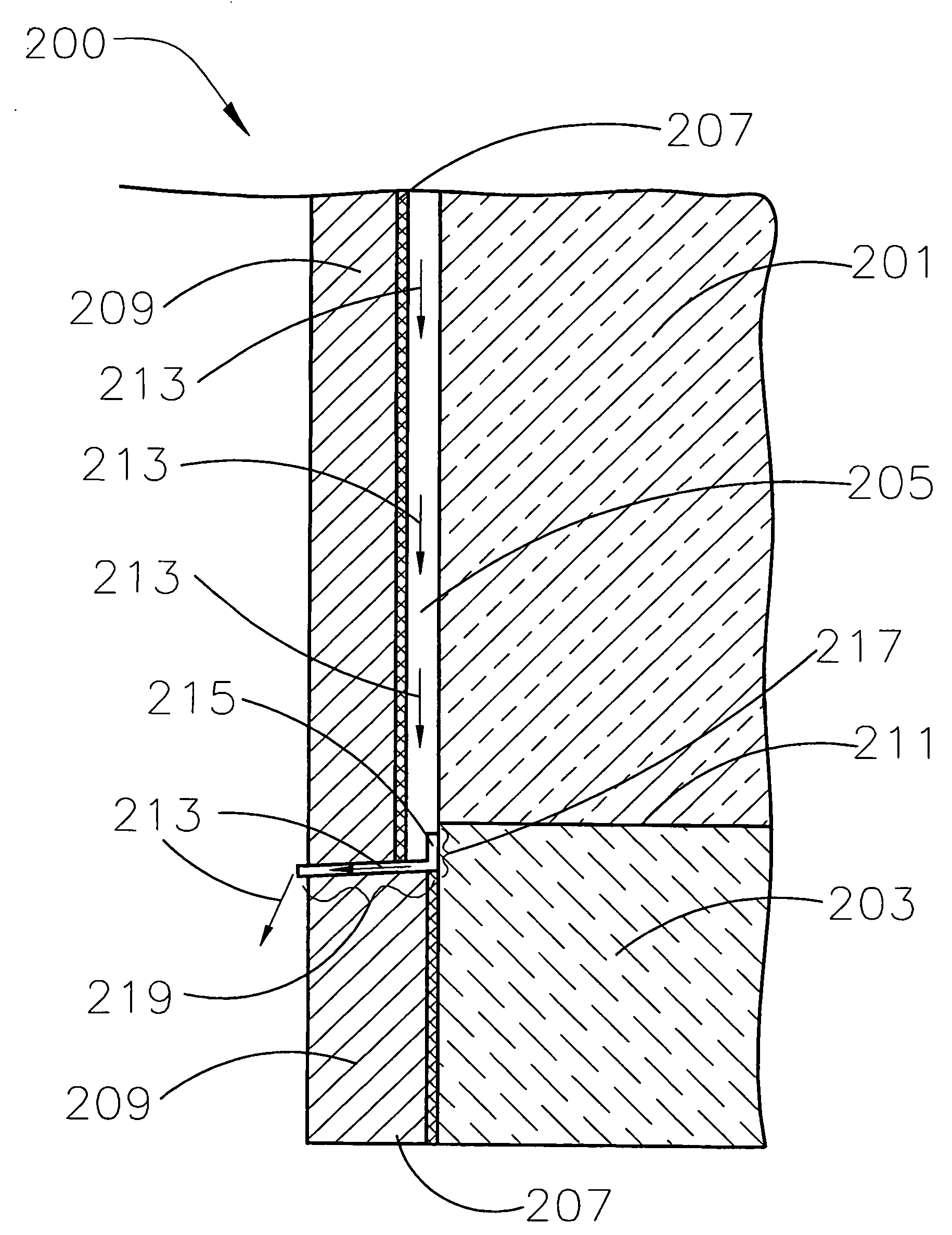

[0022]FIG. 1 shows a wall system having a known moisture drainage system. The wall system 100 includes an interior wall structure 101 disposed on a foundation 103. An interior cavity 105 is present between the interior wall structure 101 and a metal lath 107. The metal lath 107 may be present as a base for plaster or adhesive application, onto which a surface facing 109 may be applied. The surface facing 109 is applied to the metal lath 107. The surface facing 109 and metal lath 107 extend along the surface of the interior wall structure 101, but terminate at the interface 111 between the foundation 103 and the interior wall structure 101. Moisture formed or present in the interior cavity 105 flows in the direction of gravity toward the interface 111. The flow of moisture is shown in FIG. 1 as flow 113. The moisture is removed from the interior cavity 105 through the bottom of the interior cavity 105 and out of the wall system 100. This system suffers from the drawback that at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com