Metal fiber comprising more than one metal or metal alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

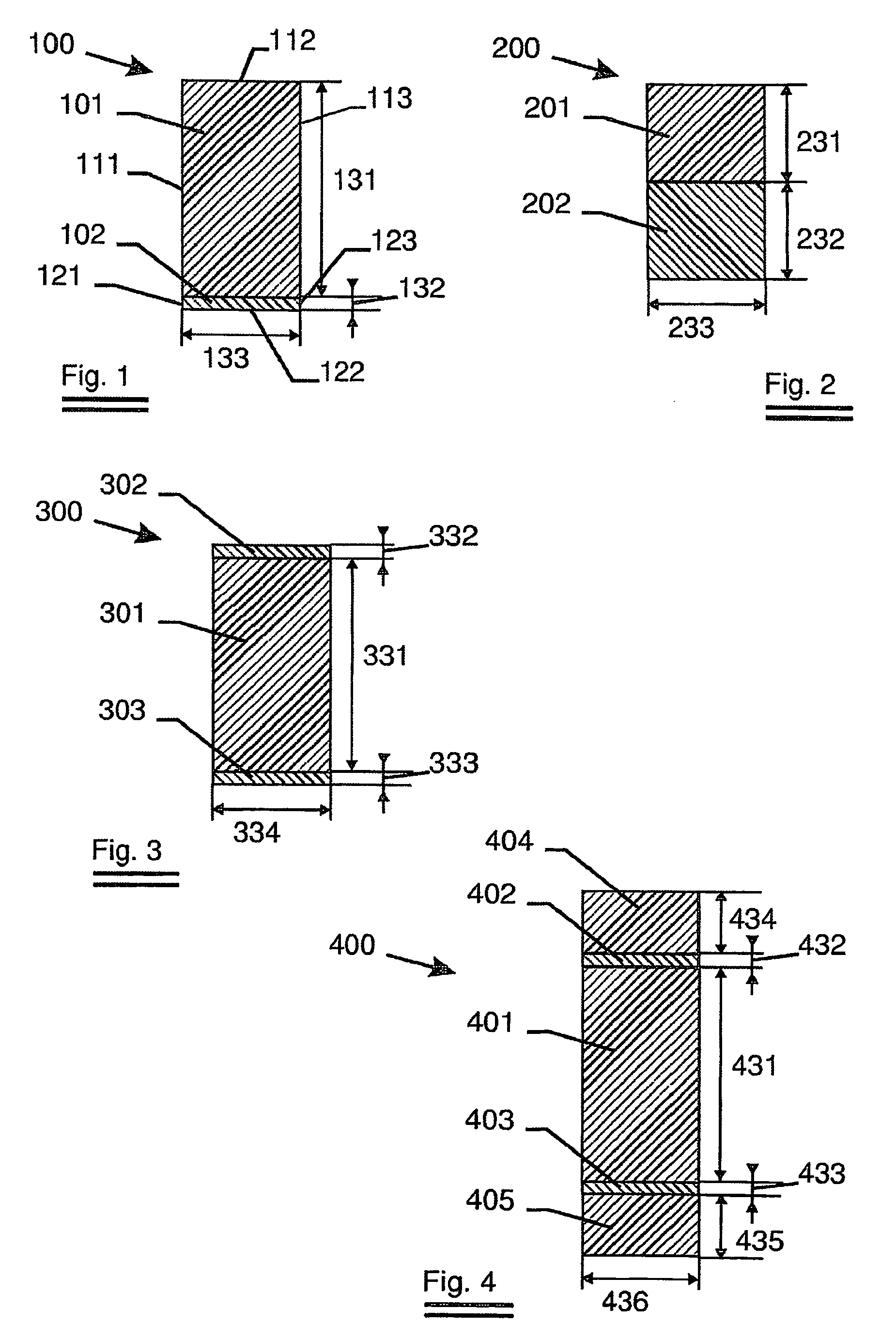

[0047] A cross section of a metal fiber 100 as subject of the invention is shown in FIG. 1. The metal fiber cross section 100, which is substantially polygon, in this case quadrangular, even substantially rectangular. comprises a first zone 101 and a second zone 102. The first zone 101 is provided using a first metal M1, as an example a stainless steel alloy comprising aluminum, chromium and iron. This first zone 101 provides the sections 111, 112 and 113 of the perimeter of the metal fibers cross section. the second zone 102 provides the sections 121, 122 and 123 of the perimeter of the metal fibers cross section. As an example the metal used to provide the second zone is Pd.

[0048] As an example the metal fiber 100 of FIG. 1 has an equivalent diameter R. This means that the surface π*R2 / 4 is equal to the multiplication of the fiber first side length 133 with the sum of the layer thickness 131 and 132 of the first zone 101, respectively second zone 132. As an example, the metal fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com