Electrically controlled tiltable microstructures

a microstructure and tilting technology, applied in the field of microstructures, can solve the problems of difficult to achieve a flat mirror surface, temperature and material limitations, and difficult to achieve both qualities in micromachined devices, and achieve the effect of large tilting angle and large fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

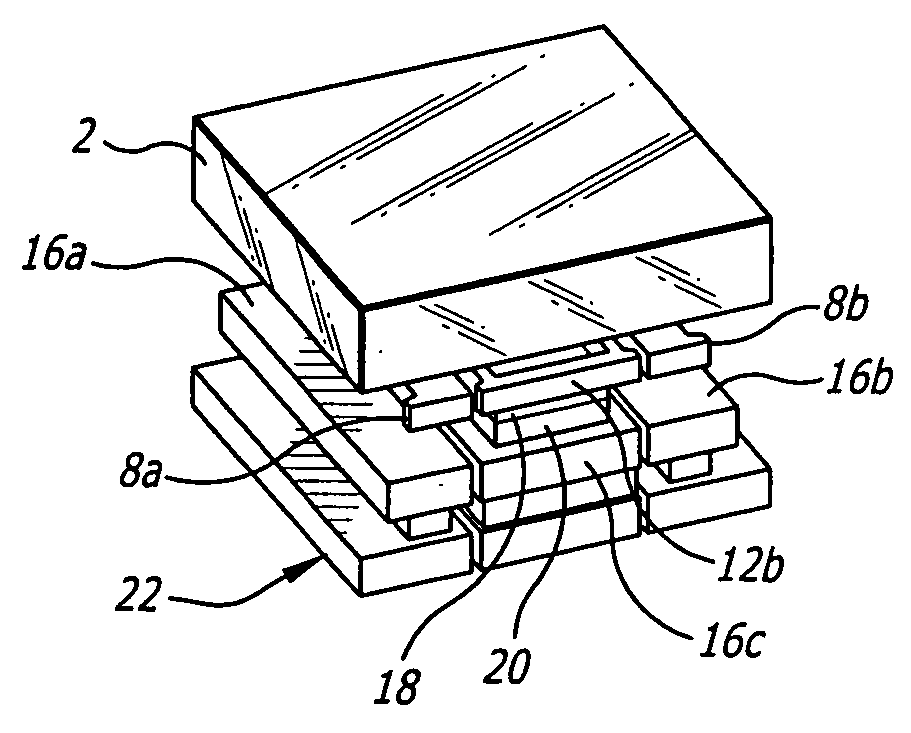

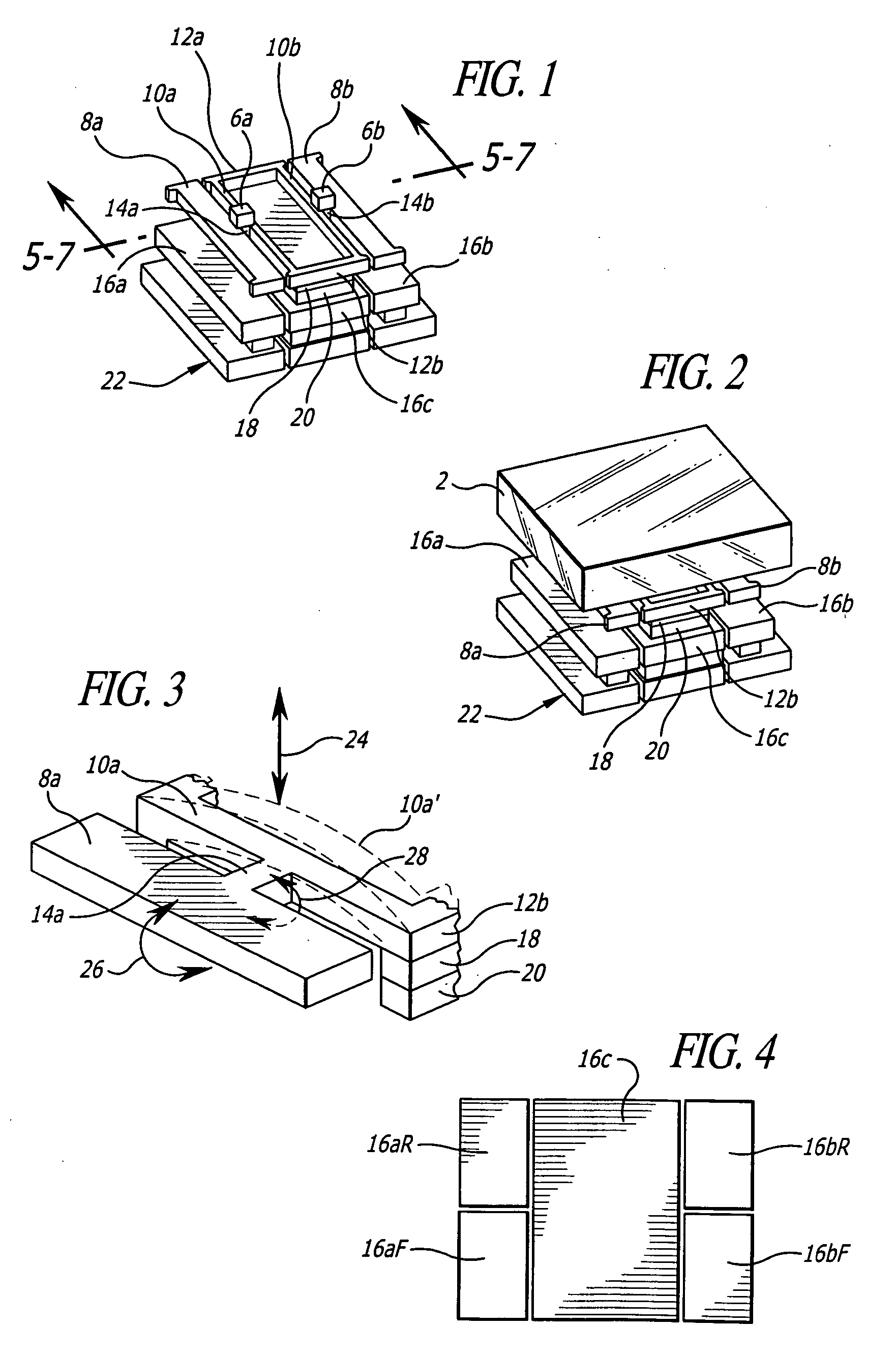

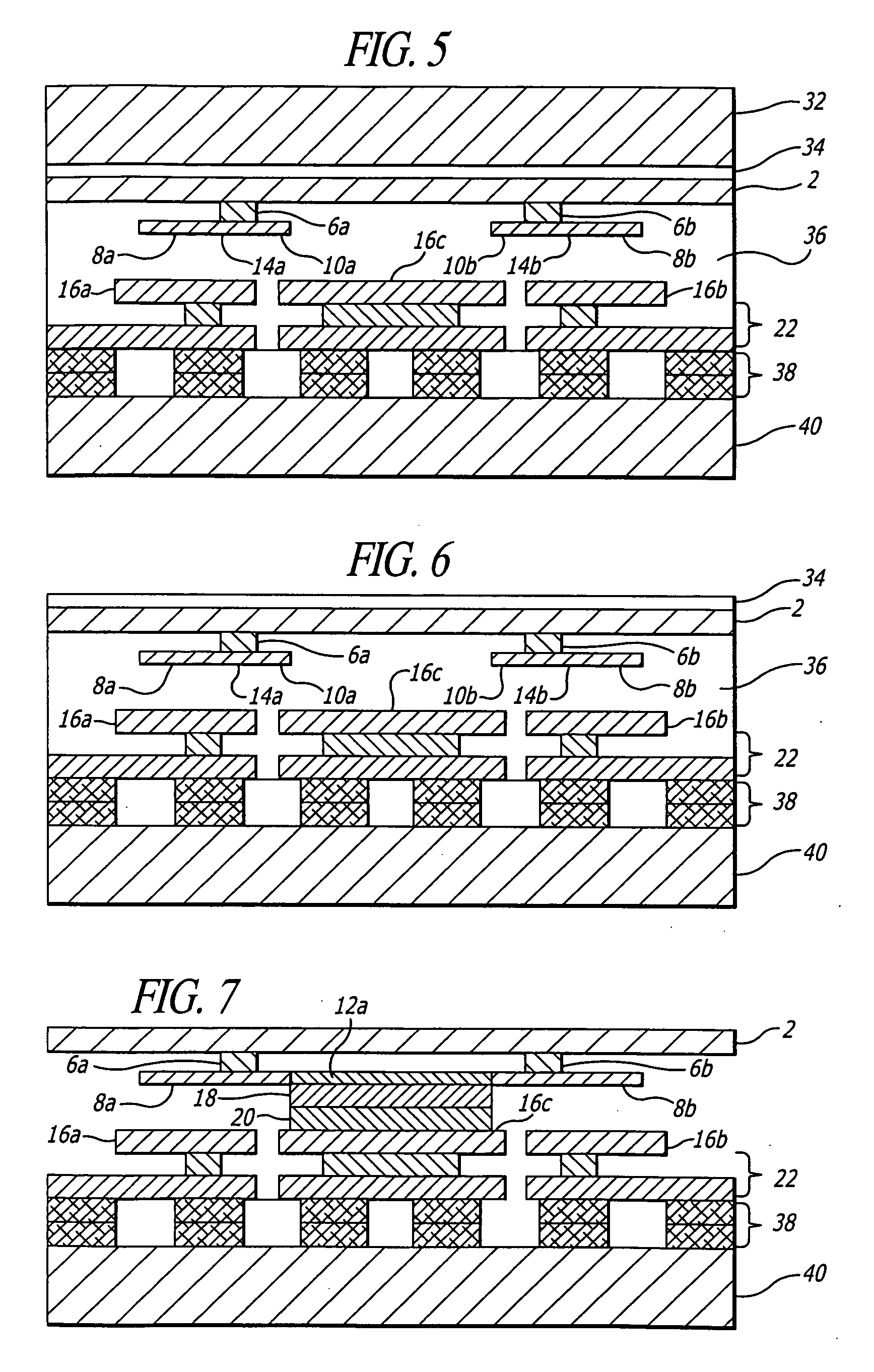

[0024] An illustrative microstructure device which supports a tiltable platform in accordance with the invention is illustrated in FIGS. 1 and 2. As used herein, the term “platform” includes a mirror but is not limited to mirror applications; it can also provide a base for other functions such as filters, gratings, and non-optical applications.

[0025] Although not required by the invention, the fabrication preferably employs a hybrid micromachining approach that combines bulk and surface micromachine techniques. This approach to forming a microstructure is disclosed in U.S. Pat. No. 6,587,613 by the present inventor, issued Jul. 1, 2003, the contents of which are incorporated by reference herein. It involves the formation of a support structure for a bulk micromachined element by fabricating the support structure on the element using surface micromachining techniques. One implementation uses a 5-level surface micromachining technology that allows for the fabrication of complex movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com