Self-cleaning oven

a conveyor oven and oven technology, applied in the field of self-cleaning ovens, can solve the problems of increasing the cost of installing high-current electrical services, affecting the quality of food products cooked, and becoming rather dirty. , to achieve the effect of optimizing fuel consumption, optimizing food products cooked quality, and cleaning clean and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

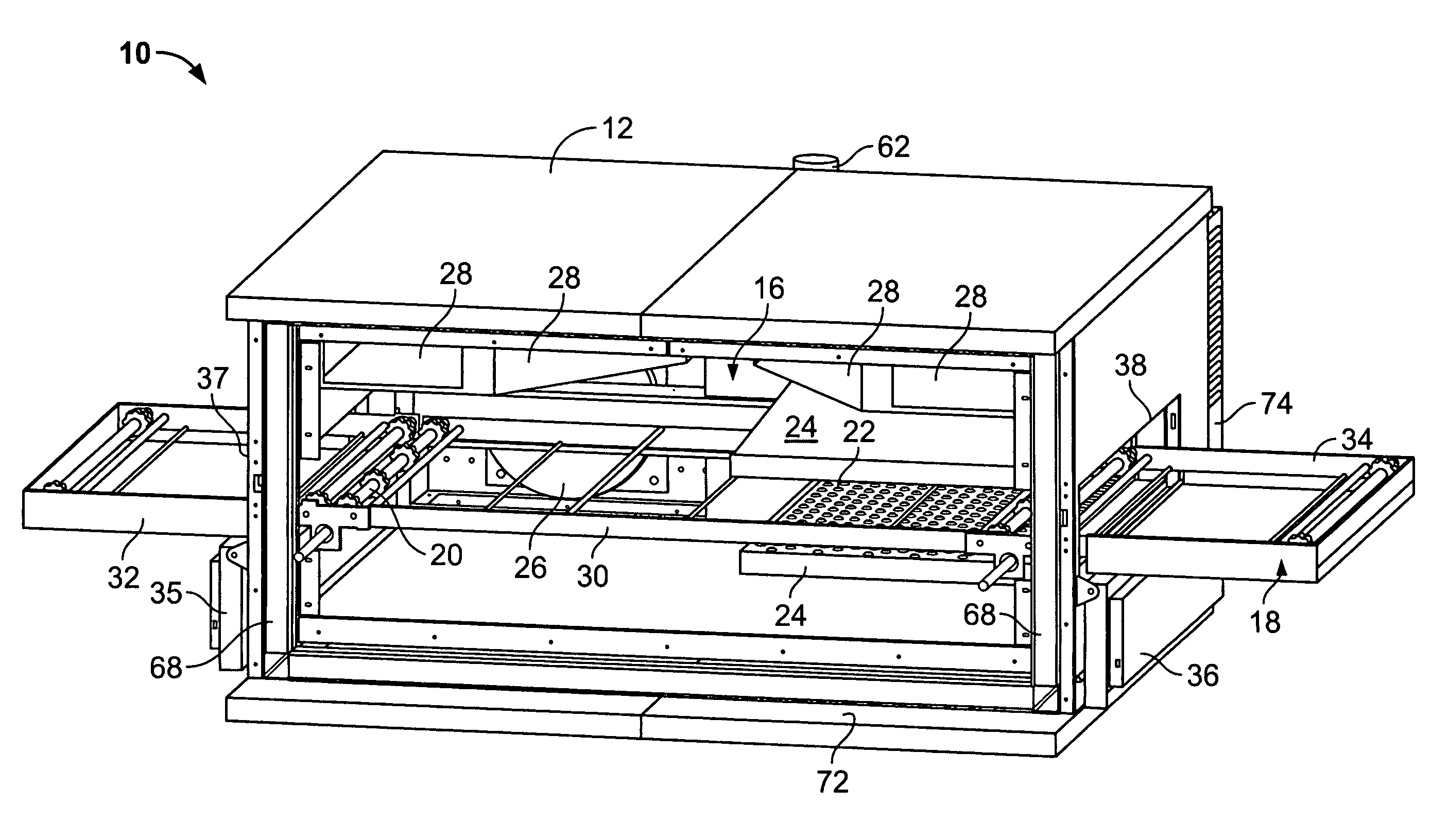

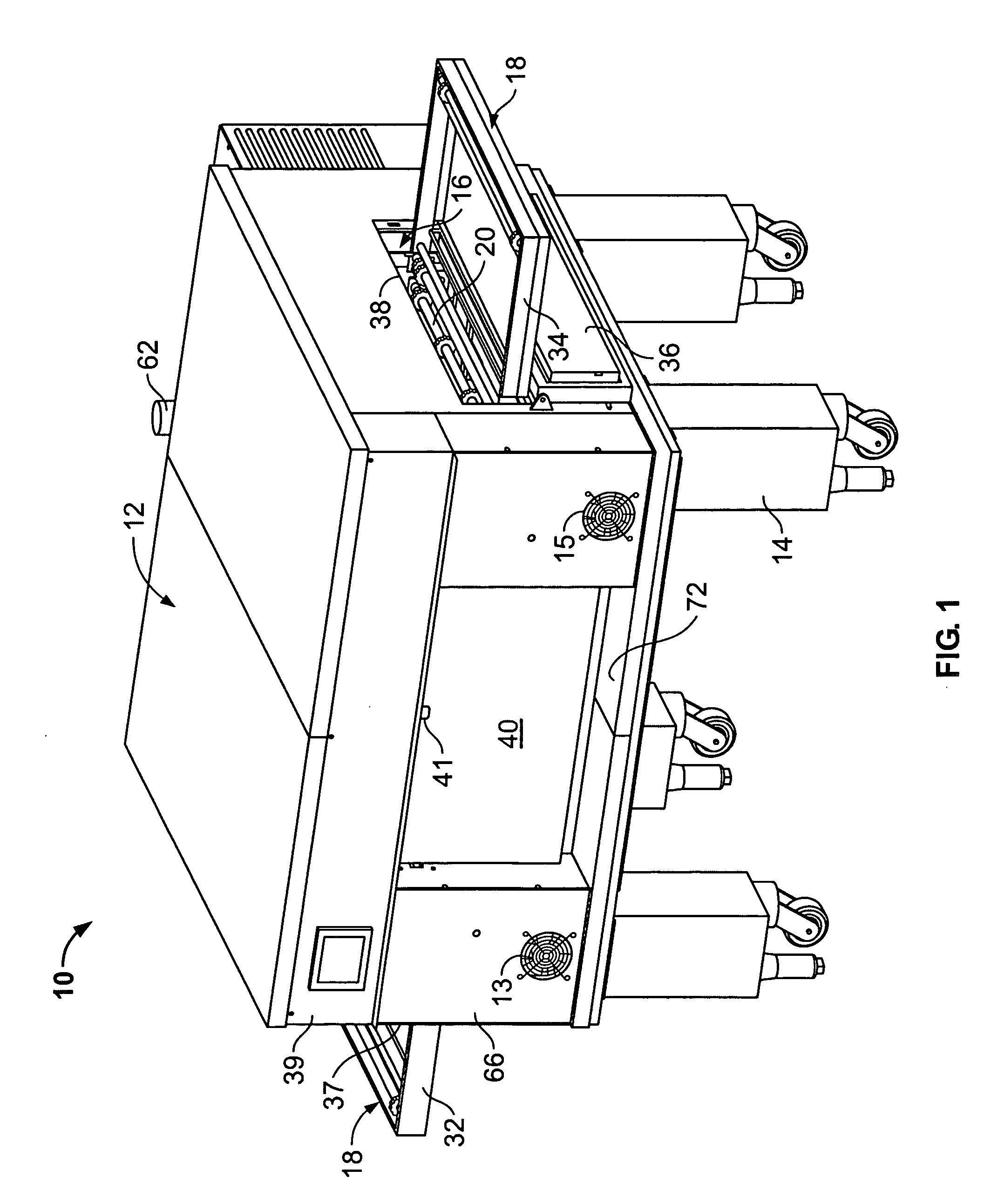

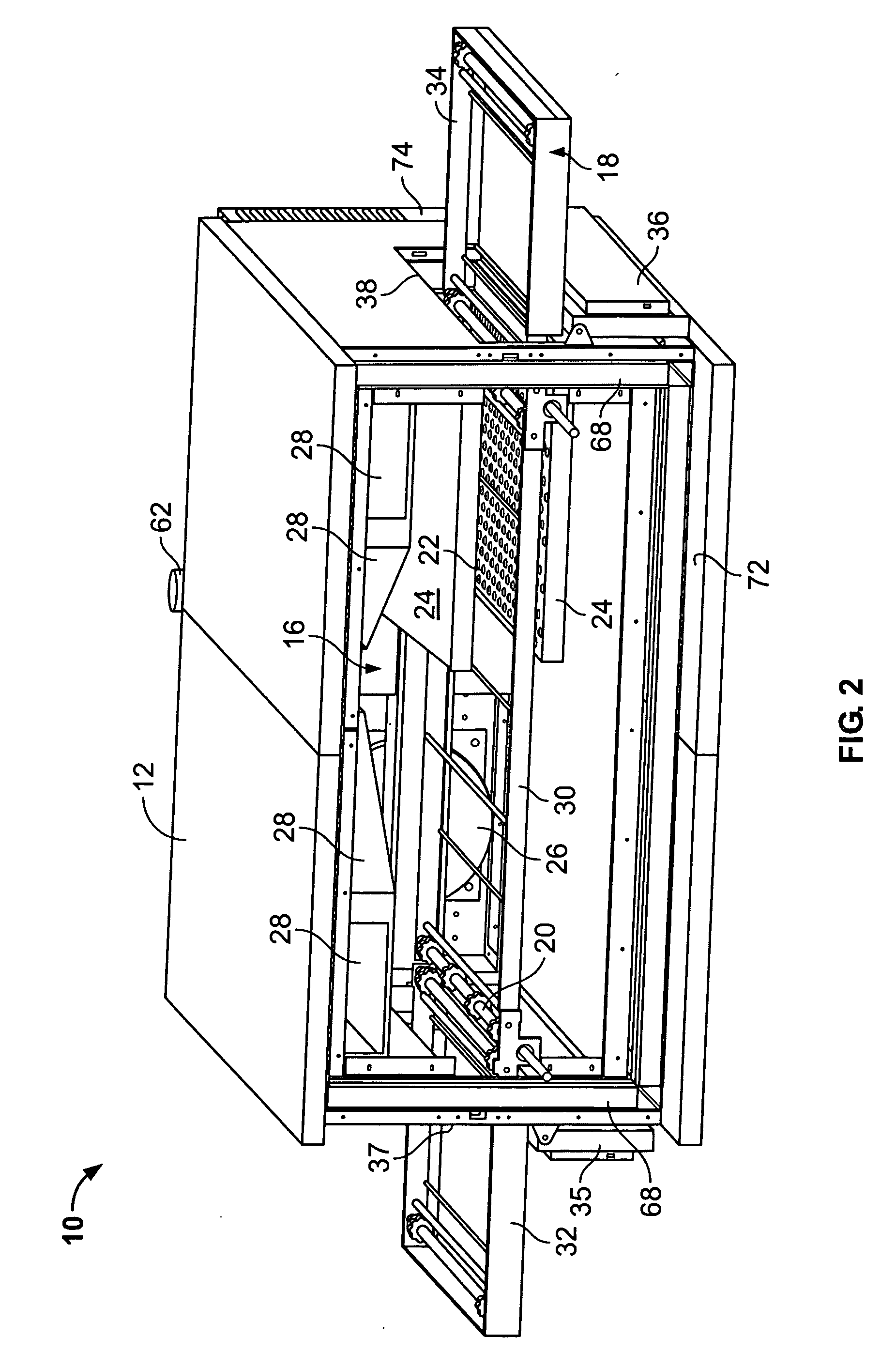

[0029] According to one embodiment, a pyrolytically self-cleaning, gas-fired, conveyor oven 10, as shown in FIG. 1, includes an oven housing 12 supported on four legs 14. The oven housing 12 surrounds a cooking chamber 16 through which food products are passed on a conveyor assembly 18. The oven 10 also includes a front access door 40 that can be opened using a front access door handle 41.

[0030] As best seen in FIG. 2, the conveyor assembly 18 includes powered rollers 20 that drive a wire mesh conveyor belt (not shown in the Figures) that conveys. food through the cooling chamber 16. The powered rollers 20 can be driven in either direction so that, as viewed in FIG. 2, the conveyor belt can convey food through the cooking chamber 16 from left-to-right or right-to-left. Food products can be transported by the conveyor assembly 18 into a first oven opening 37 and out of a second oven opening 38 or, alternatively, into the second oven opening 38 and out of the first oven opening 37. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com