Heat sink structure for air mattress

a technology of air mattress and heat sink, which is applied in the direction of fluid mattresses, domestic cooling devices, sofas, etc., can solve the problems of exhausting air taking heat and damp away, unable to be too big, and unable to cool down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

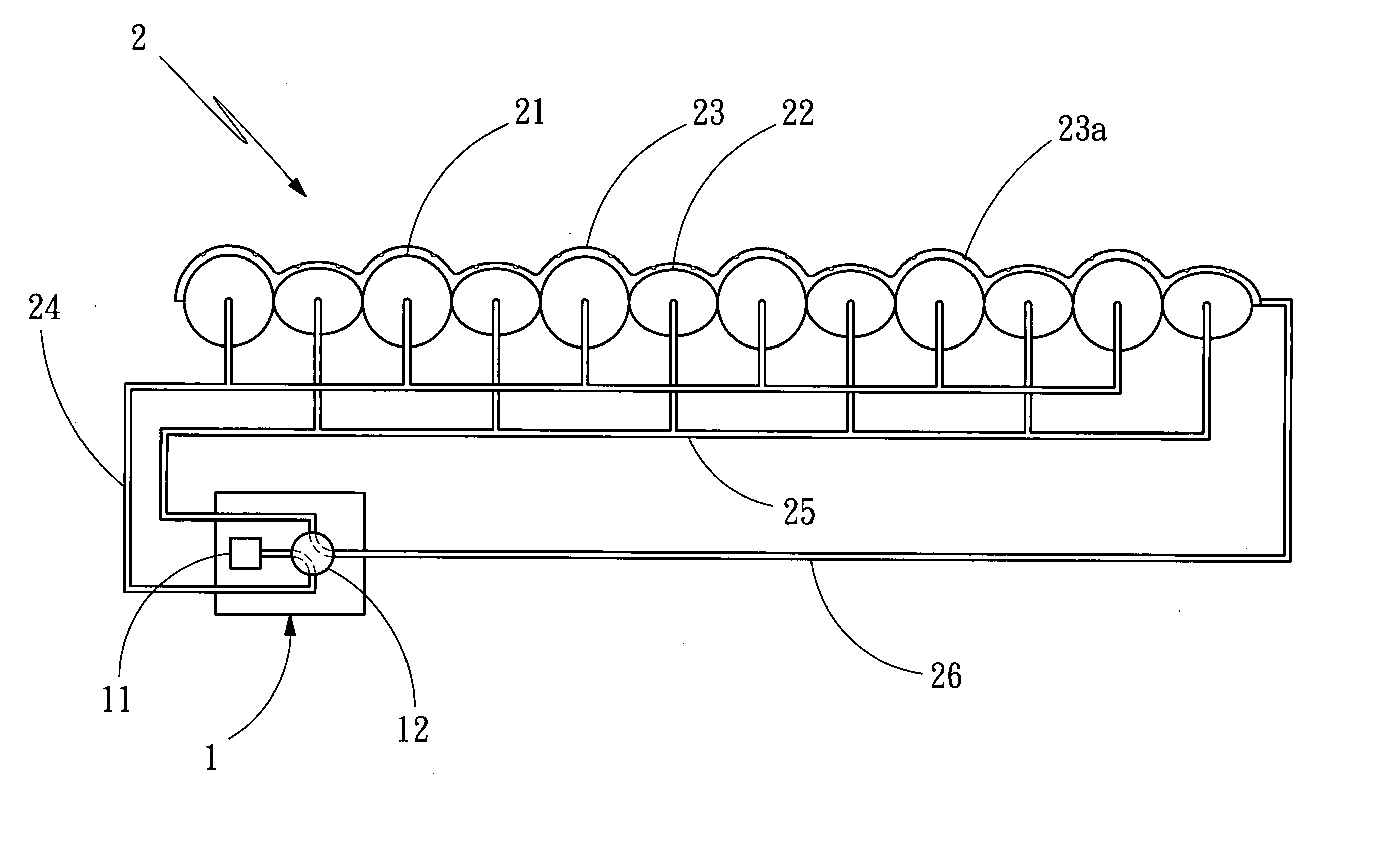

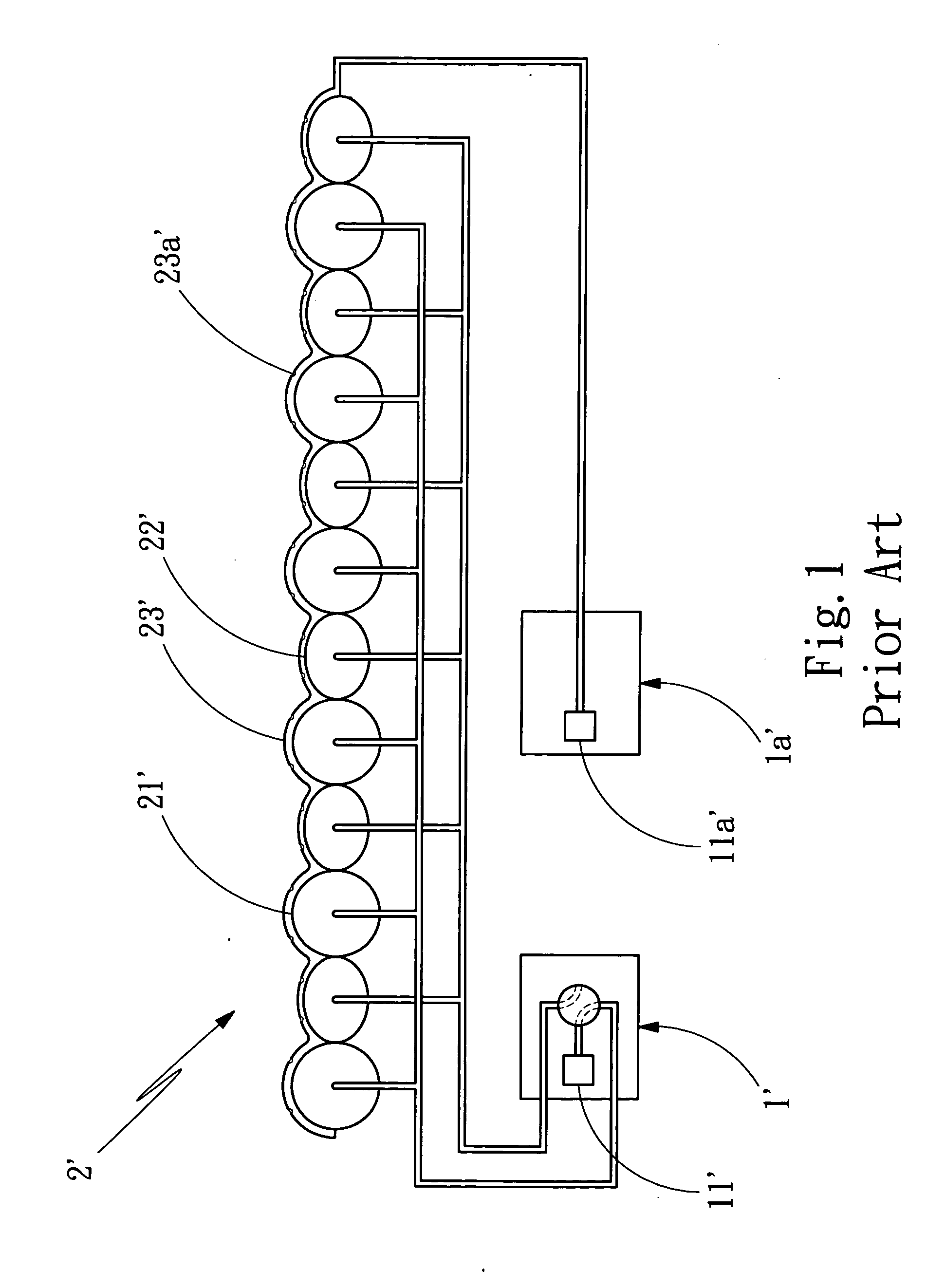

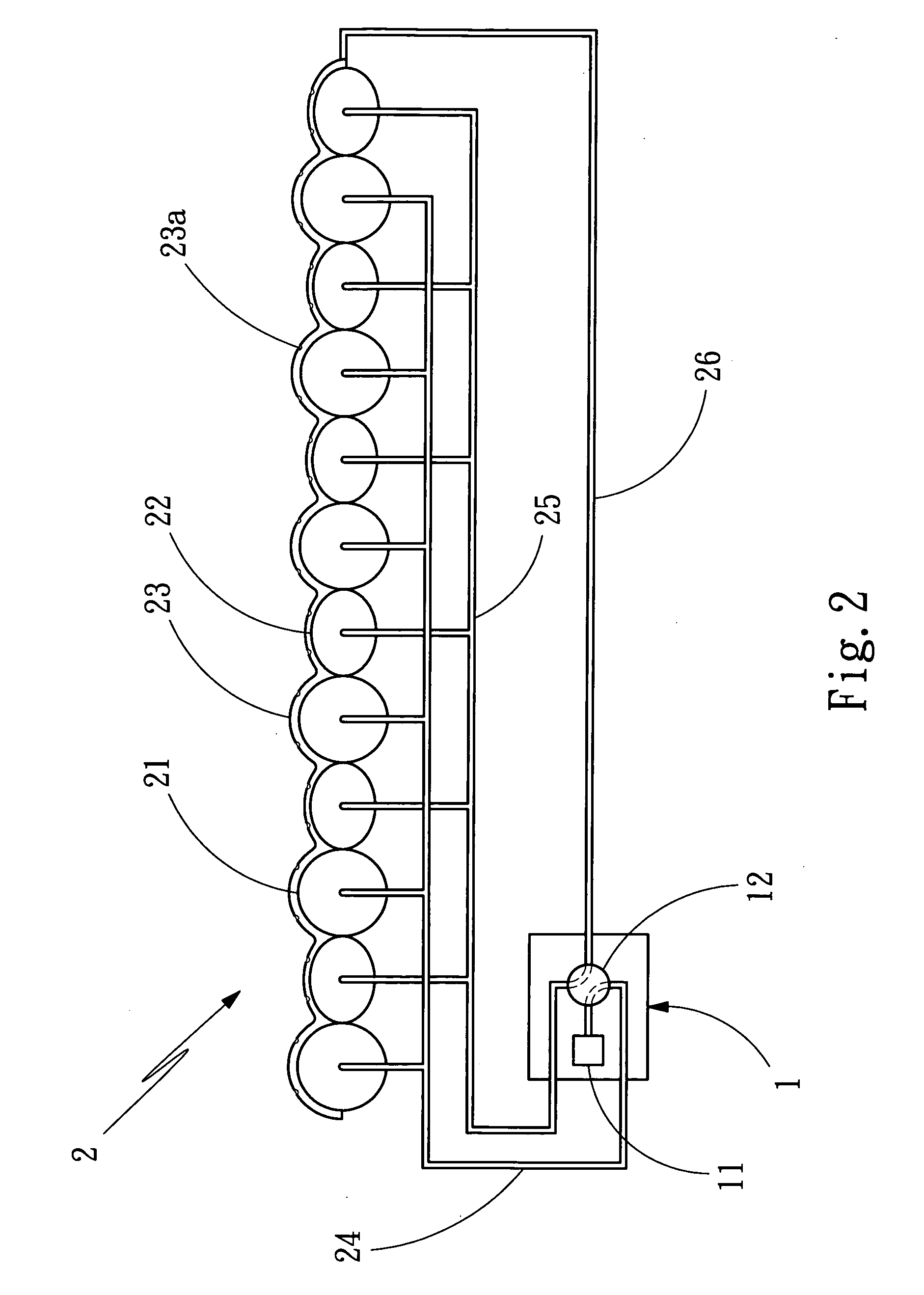

[0015] With reference to FIG. 2, the heat sink structure for air mattress in accordance with the present invention is mainly composed of a control unit (1) and an air mattress (2). The said control unit (1) has an air pump (11) and a controlling valve (12). The air pump (11) is a powered device for supply of compressed air, and the controlling valve (12) is a fluid connector for selecting some of components to connect. The air mattress (2) has a plurality of first airbags (21), a plurality of second airbags (22), and a heat sink layer (23), and there are numbers of the first airbags (21) and second airbags (22) arranged designedly while each airbag is a cannular structure which is expanded with pumping up and shrunken with draining off; and the heat sink layer (23) is a hollow structure made of breathed material, and some kinds of this material is porous material. As described above, the first airbags (21), the second airbags (22), and the heat sink layer (23) are connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com