Ribbon hub and spool assembly

a technology of hub and spool, which is applied in the direction of printing and inking apparatus, etc., can solve the problems of awkward and difficult procedures, and the alignment can be very difficul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

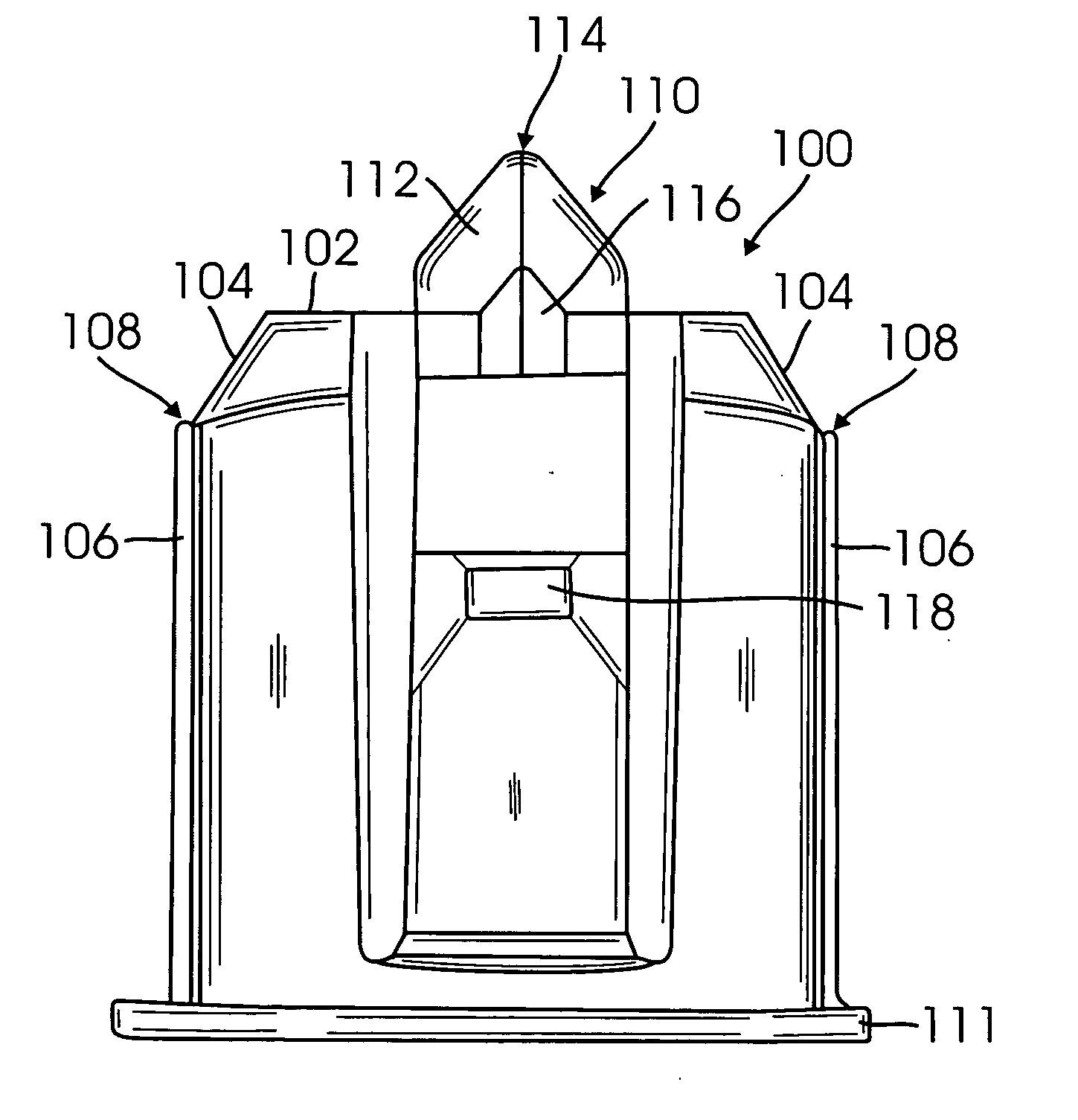

[0026] According to one embodiment of the present invention, a hub and spool assembly for a printer system includes a hub with at least two tapered cantilever beams, rounded splines, and a tapered top, and a spool having rounded and tapered splines and a tapered opening.

[0027]FIG. 6 is a side view of a hub 100 according to one embodiment of the invention. FIG. 7 is a perspective view of hub 100, and FIG. 8 is a top view of hub 100. Hub 100 can be a motor-driven hub for use in an impact printer system. In this embodiment, hub 100 has a top flat surface 102 with an angled or tapered portion 104 extending to the outer circumference of the hub. A plurality of splines 106 is located along the outer circumference of the hub, where splines 106 extend parallel to the axis of rotation. Each spline 106 has a rounded or curved top portion 108 at or near angled portion 104.

[0028] Hub 100 also has two opposing cantilever beams 110. Other embodiments can have more than two such beams. Beams 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com