Total heat exchanger and ventilation system using the same

a technology ventilation system, which is applied in the direction of ventilation system, domestic cooling apparatus, heating types, etc., can solve the problems of limited height of total heat exchanger, affecting the efficiency of ventilation system,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

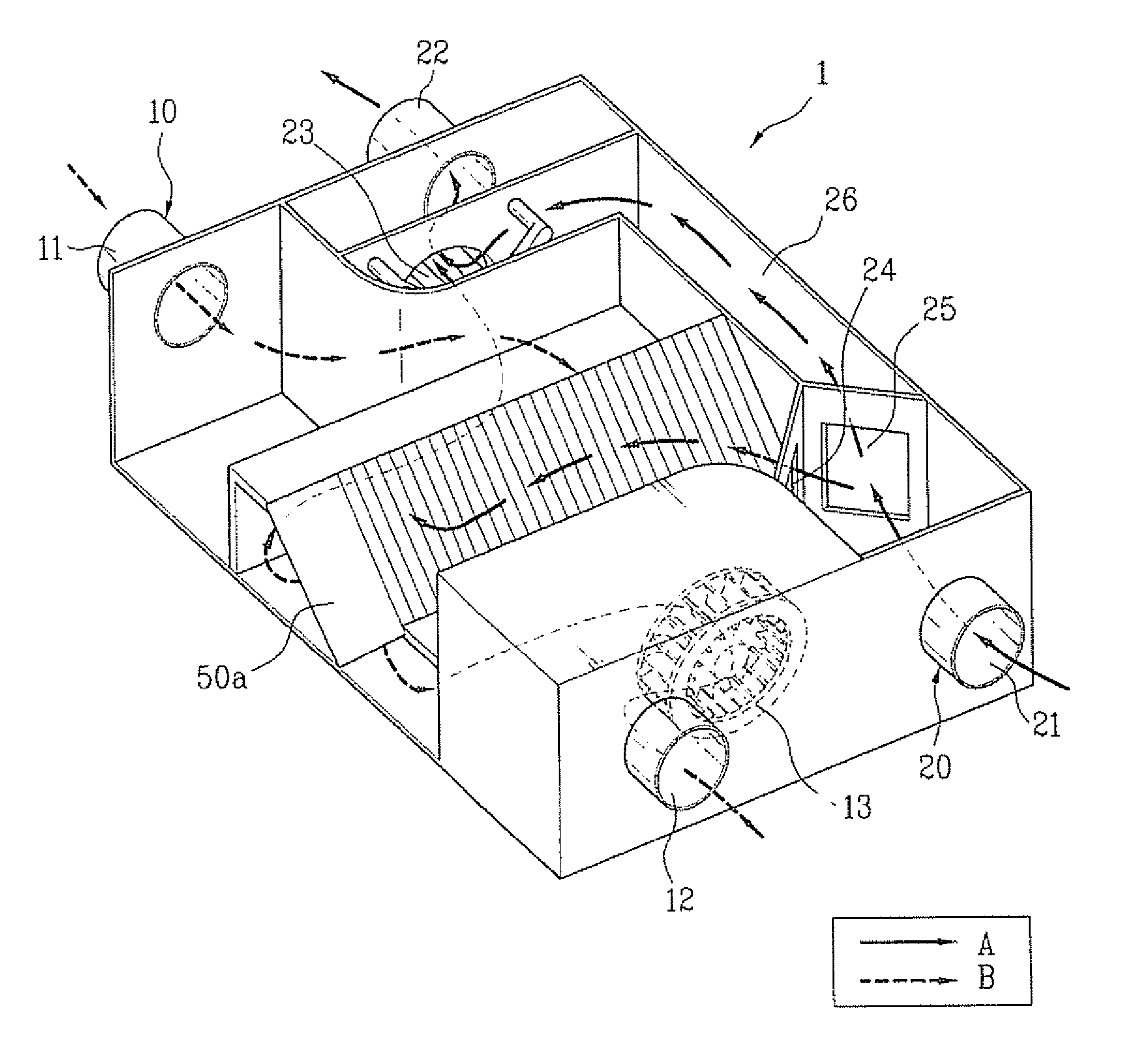

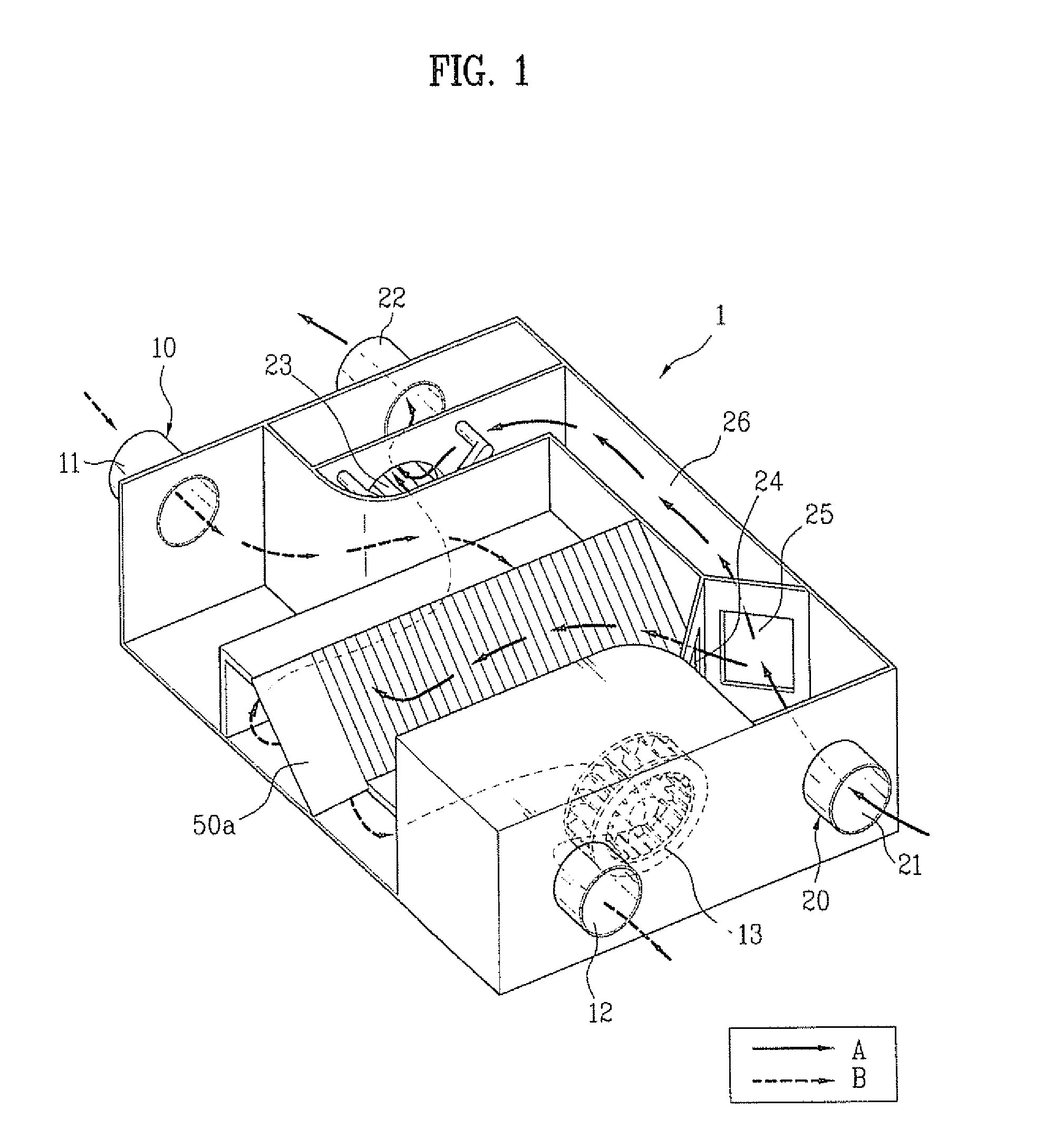

[0045] Hereinafter, the total heat exchanger according to the present invention will be described with reference to FIGS. 1 to 3B.

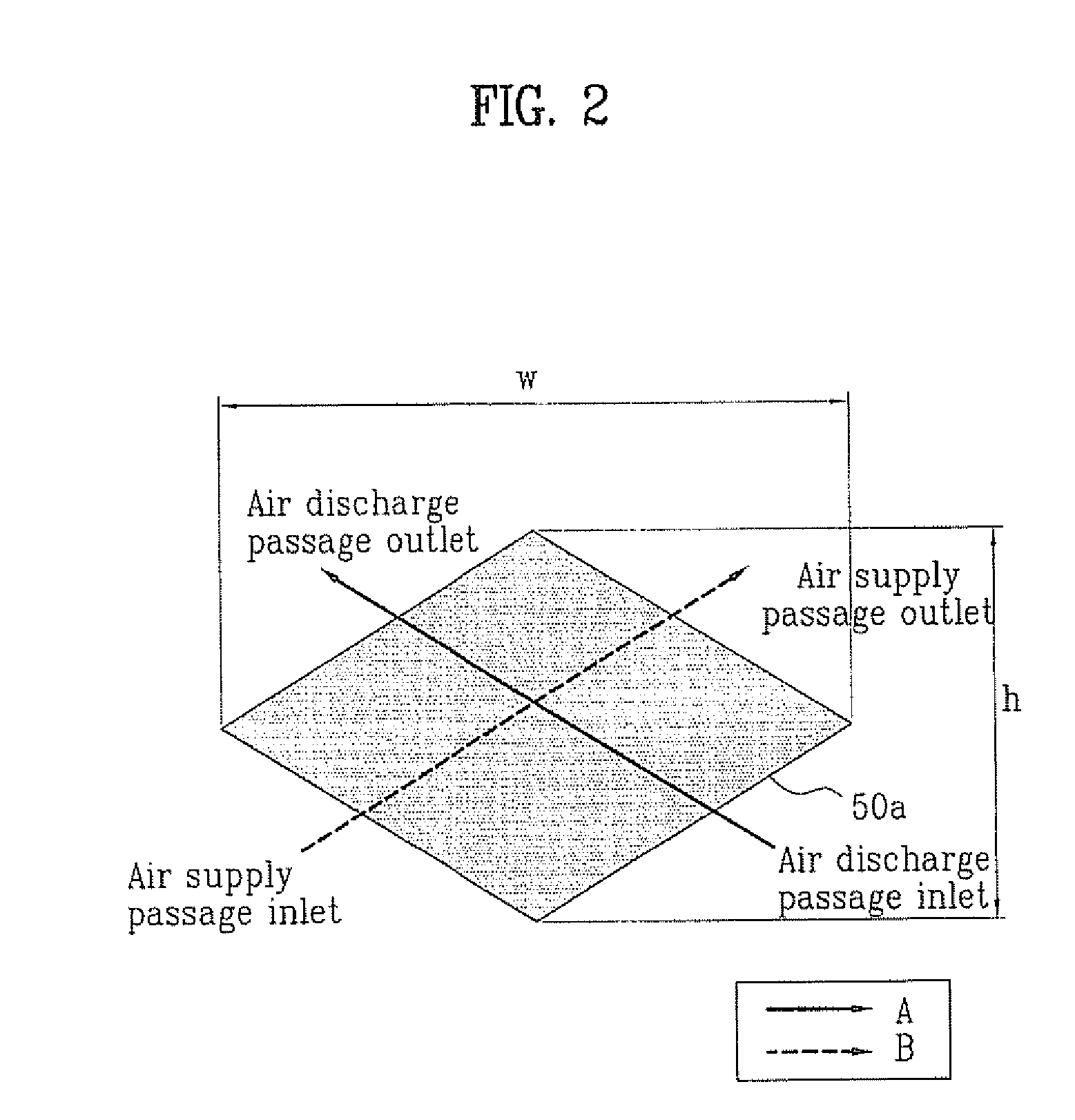

[0046] The total heat exchanger includes an air supply duct 10 for guiding outdoor air to an indoor space, an air discharge duct 20 for guiding indoor air to the outdoors, and a heat exchanging element 50a for heat-exchanging the indoor air with the outdoor air. The total heat exchanger may further include an air supply fan 13 for sucking the outdoor air, and supplying the sucked air to the indoor space, and an air discharge fan 23 for sucking the indoor air, and discharging the sucked air to the outdoors.

[0047] The heat exchanging element 50a is arranged at a region where an outdoor air flow guided by the air supply duct 10 and an indoor air flow guided by the air discharge duct 20 cross each other. The heat exchanging element 50a heat-exchanges the indoor air with the outdoor air through exchange of sensible heat using a temperature difference between ...

second embodiment

[0073] Hereinafter, the total heat exchanger according to the present invention will be described with reference to FIGS. 4 and 5.

[0074] The basic configuration of the second embodiment of the total heat exchanger according to the present invention is identical to that of the first embodiment as described above. In the second embodiment, however, the total heat exchanger includes a plurality of heat exchanging elements 50b arranged in series in a flow direction of air in the total heat exchanger.

[0075] As described above, there is a restriction in increasing the cross-sectional height of a heat exchanging element due to restrictions in the design of the construction in which the total heat exchanger is installed. When the heat exchanging elements 50b are arranged in series in a flow direction of air in the total heat exchanger, it is possible to achieve an enhancement in heat exchange efficiency without an increase in the cross-sectional height of the heat exchanging elements 50b. ...

third embodiment

[0083] Hereinafter, the total heat exchanger according to the present invention will be described with reference to FIG. 6.

[0084] In accordance with this embodiment, the total heat exchanger includes an air-supply-side fan-motor assembly 130 and an air-discharge-side fan-motor assembly 230.

[0085] The air-supply-side fan-motor assembly 130 includes a plurality of air supply fans 131 each having a rotating shaft extending perpendicularly to the discharge direction of outdoor air. similarly, the air-discharge-side fan-motor assembly 230 includes a plurality of air discharge fans 231 each having a rotating shaft extending perpendicularly to the discharge direction of indoor air.

[0086] The air supply fans 131 are driven by a single dual-axial motor 132. Similarly, the air discharge fans 231 are driven by a single dual-axial motor 232. Since the air supply fans 131 and air discharge fans 231 are driven by the associated dual-axial motors 132 and 232, respectively, it is possible to prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com