Method of manufacturing an individually shaped hearing device or hearing aid

a manufacturing method and technology of hearing aids, applied in the direction of deaf-aid sets, deaf-aid adaptation, electrical appliances, etc., can solve the problems of long series of trial and error steps, and achieve the effect of good approximation of acoustic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

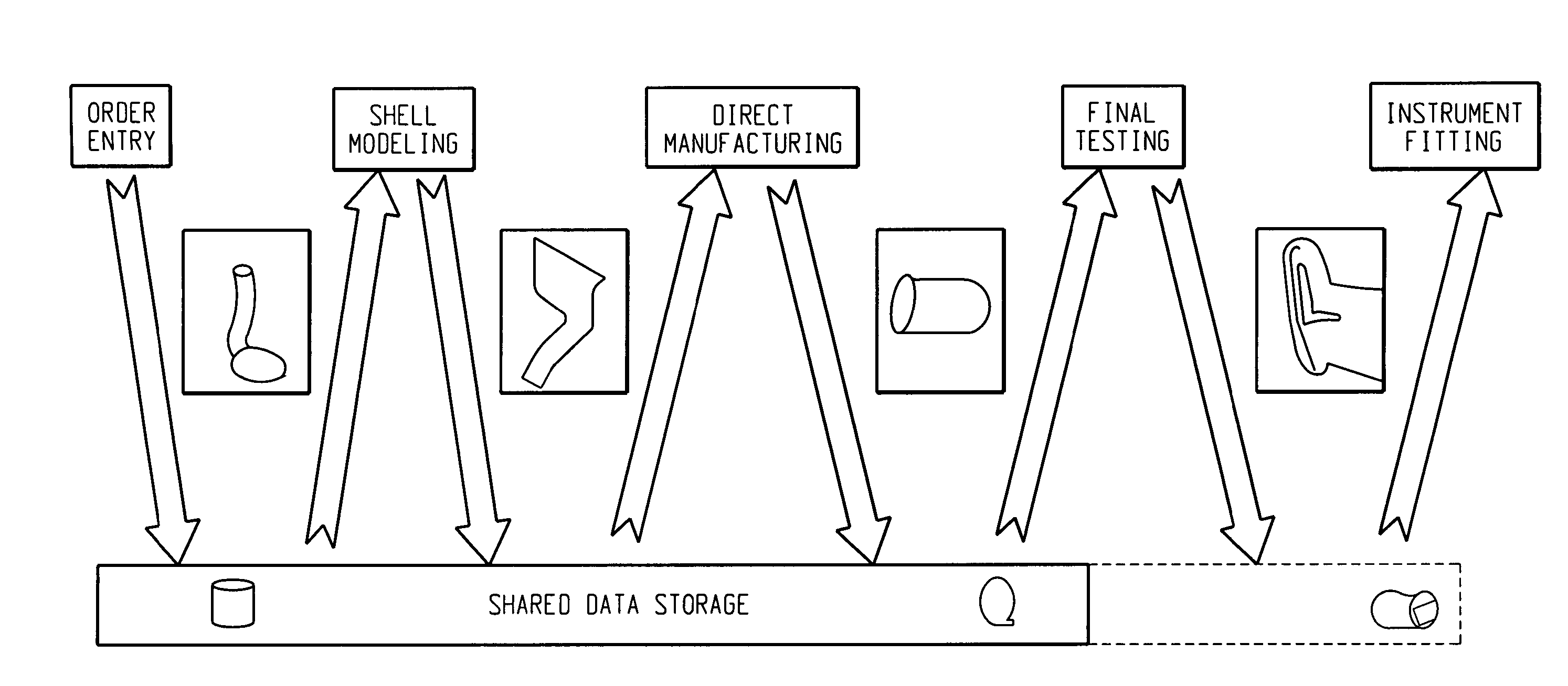

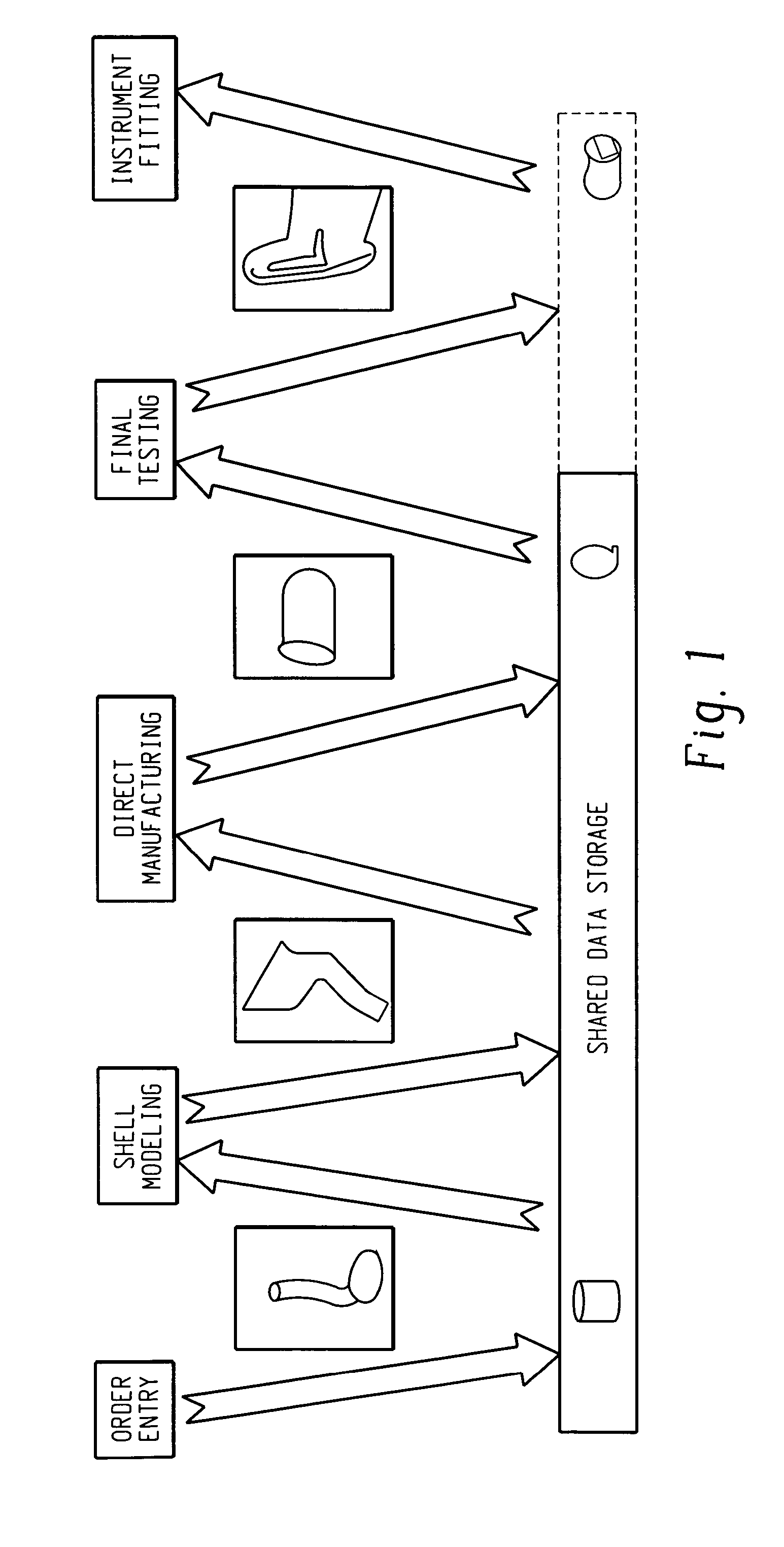

[0027] Referring to the only figure, the process of manufacturing an individually shaped or customized hearing device in form of a miniaturized in-the-ear hearing aid starts at the moment of ordering such a device and ends with the final fitting process. In the upper part of the figure, the individual stages of ordering and manufacturing are shown while in the middle part the actual shape or stage of the hearing device shell is exemplary shown in small pictures.

[0028] The data storage is schematically shown as a bar in the lower part of the figure in order to manifest its accessibility during the whole process at each process step. The accessibility is independent of the location of the ordering and manufacturing process. At each process step, new data such as geometry data will be stored into the data storage and eventually read out of the data storage for input into one or more of the following process steps.

[0029] In one embodiment of the invention, this data storage is a centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com