Radiator core support structure and its assembly method

a technology of supporting structure and radiator, which is applied in the direction of vehicle components, propulsion parts, lighting and heating apparatus, etc., can solve the problems of large gaps that are unavoidable, and achieve the effect of reducing impact and easy sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

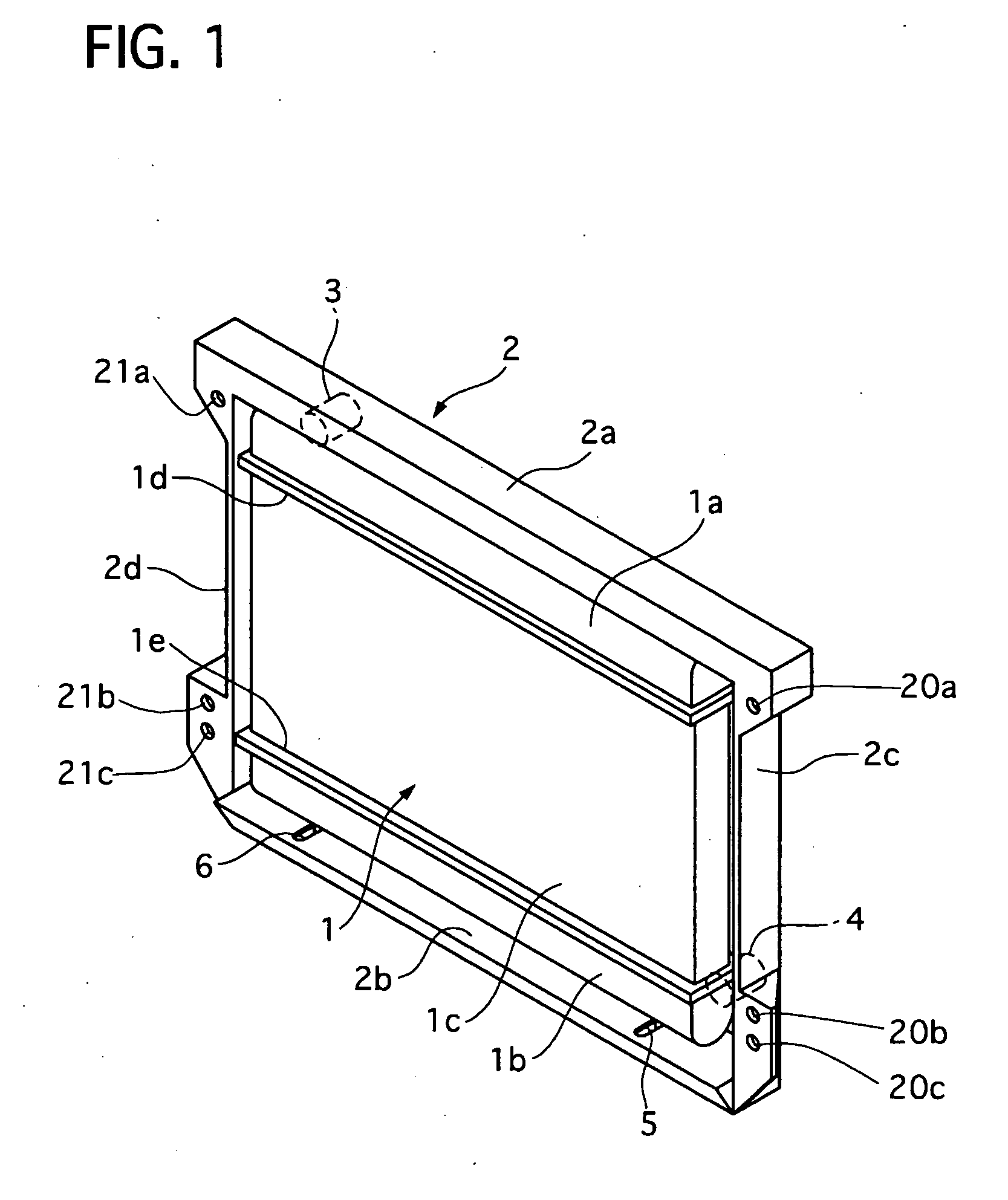

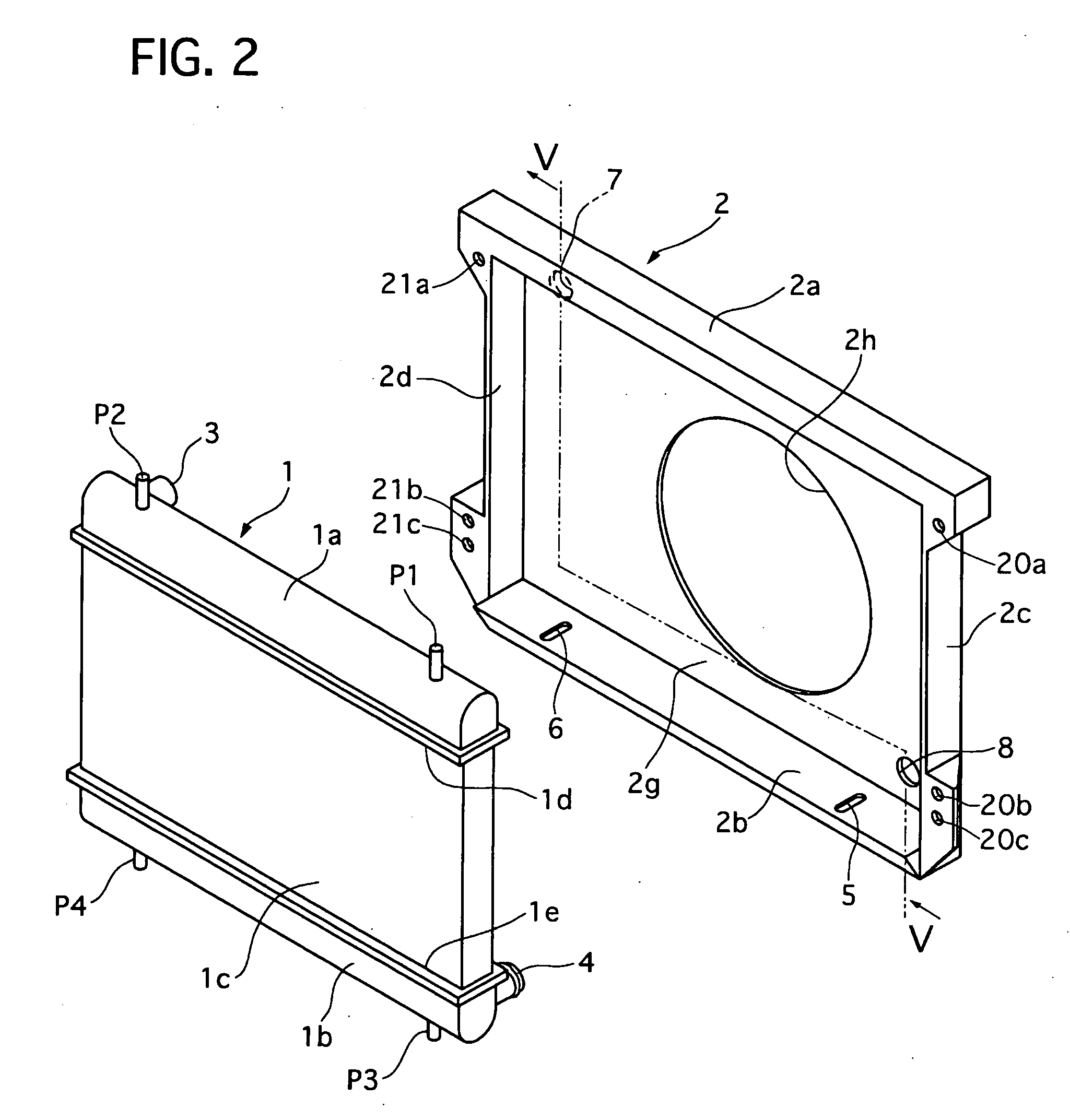

[0057] A radiator core support structure of a first embodiment according to the present invention will be described with reference to the accompanying drawings. In this description, the terms “right”, “left”, “front”, “rear”, “forward” and “rearward” are those identified with respect to a vehicle body, not to those in the drawings.

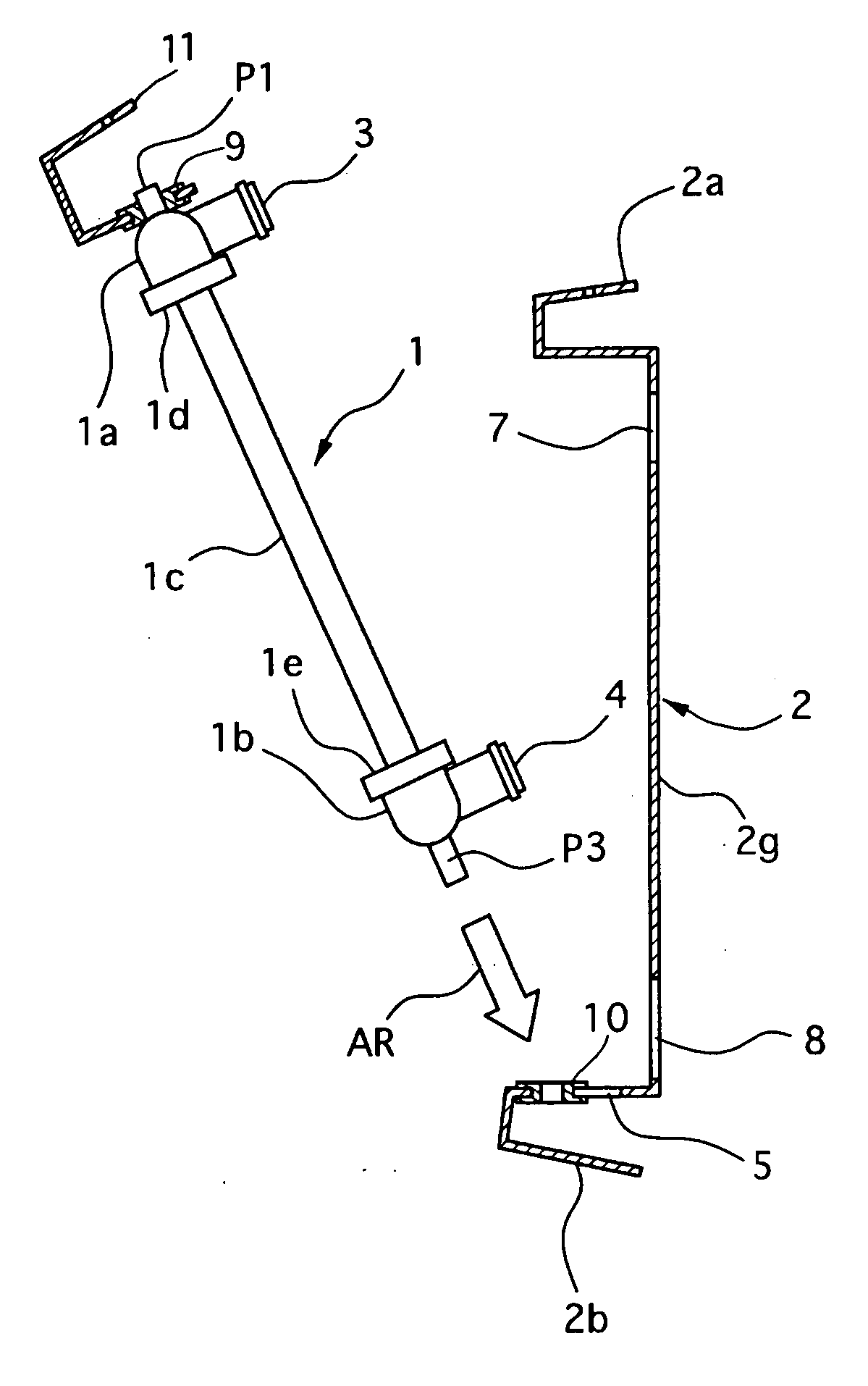

[0058] Referring to FIGS. 1 to 3, the radiator core support structure are fixed to a front part of the vehicle body, not shown, and defines an engine room together with the vehicle body. The radiator core support structure includes a radiator 1 and a radiator core support 2. The radiator 1 acts as a heat exchanger of the present invention.

[0059] The radiator 1 comprises an upper tank 1a, a lower tank 1b arranged in parallel with and under the upper tank 1a, a radiator core 1c arranged between the upper and lower tanks 1a and 1b.

[0060] The upper tank 1a is provided on its top portion with an upper left mounting pin P1 and an upper right mounting pin P2, w...

second embodiment

[0094] Next, a radiator core support structure of a second embodiment will be described with reference to the accompanying drawing of FIG. 9.

[0095] The radiator core structure of the second embodiment includes a radiator 1 and a radiator core support 2. The radiator core support 2 has a lower portion 2b formed with a lower left fixing hole 5 and a lower right hole 6′, which are apart from each other in a lateral direction of the radiator core support 2.

[0096] The lower left fixing hole 5 is formed to be an elongate hole extending forward for allowing a lower left mounting pin P3 to slide along it.

[0097] The lower left hole 6′ is formed to be a round hole with a diameter slightly larger than that of the lower right pin P4. The lower left hole 6′ acts as a slide-preventing hole of the present invention.

[0098] The other parts of the radiator core support structure of the second embodiment are similar to those of the first embodiment.

[0099] In this embodiment, the lower left pin P3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com