Slide rack

a slide rack and slide technology, applied in the field of slide racks, can solve the problems of manual manipulation of the slide rack, relatively high cost of ball bearings or similar elements,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

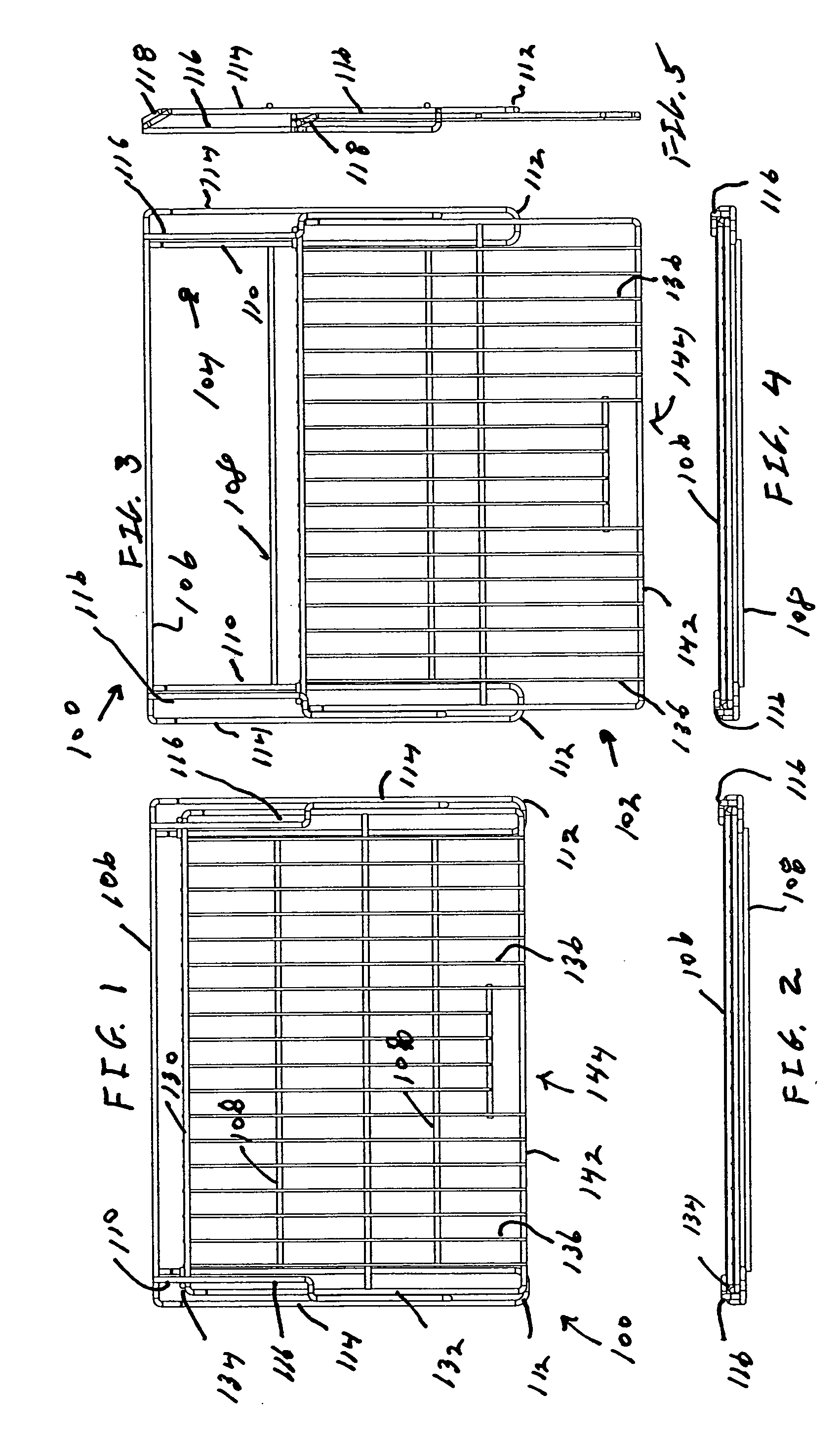

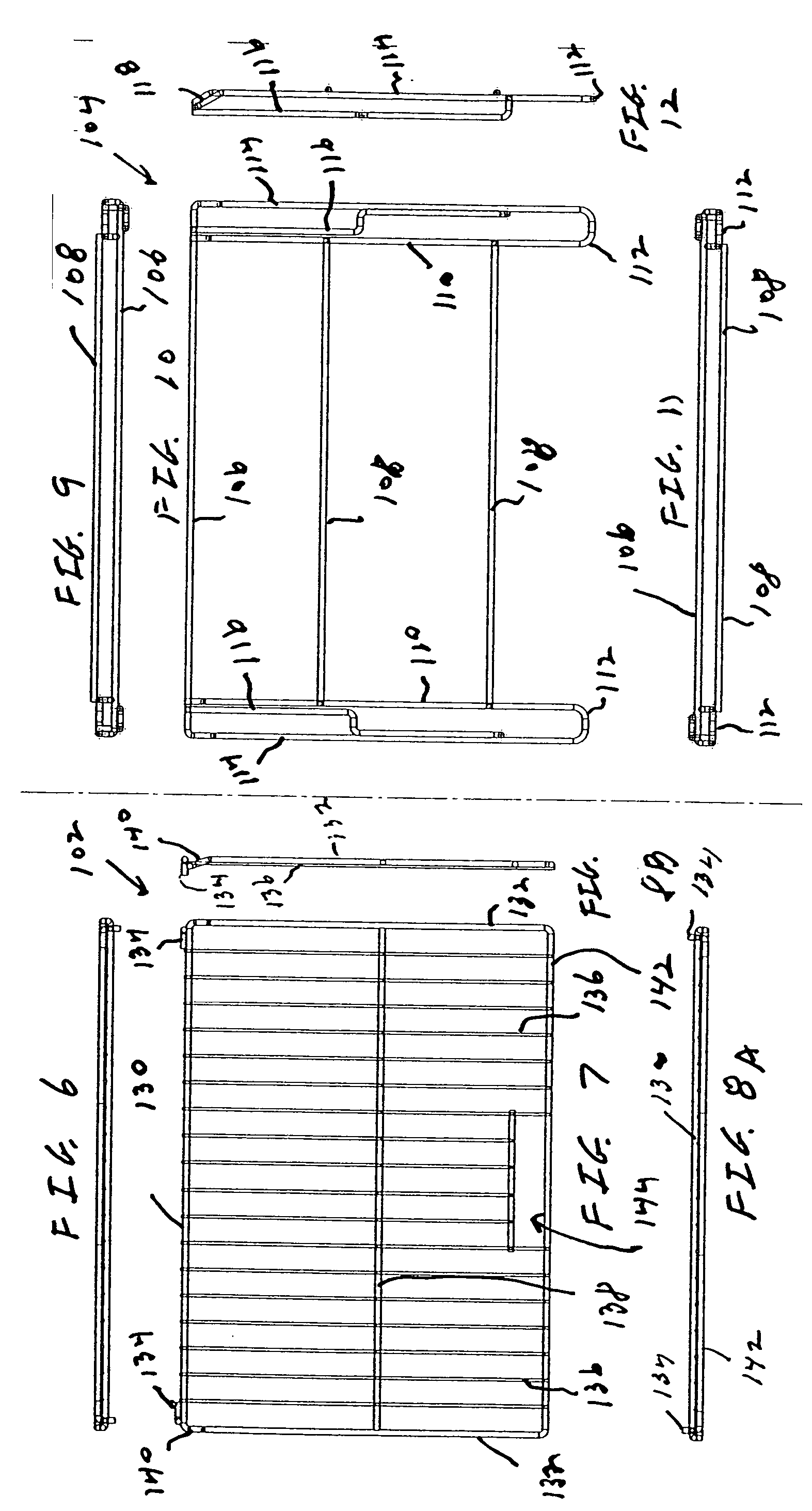

[0047] More specifically, and first with respect to FIGS. 1-12, a two piece oven rack 100 is illustrated in accordance with the invention. The two piece oven rack 100 includes a cooking rack 102 (shown in a stand alone configuration in FIGS. 7-8B) and a base rack 104 (shown in a stand alone configuration in FIGS. 9-12). Referring specifically to the base rack 104, the rack 104 includes an elongated rear brace 106 which extends horizontally along the back of the base rack 104. The elongated rear brace will be positioned adjacent the rear of the oven cavity. It should be emphasized that the base rack 104 is adapted to remain stationary and may be positioned on ledges or other protrusions associated with the inner liners of the oven cavities.

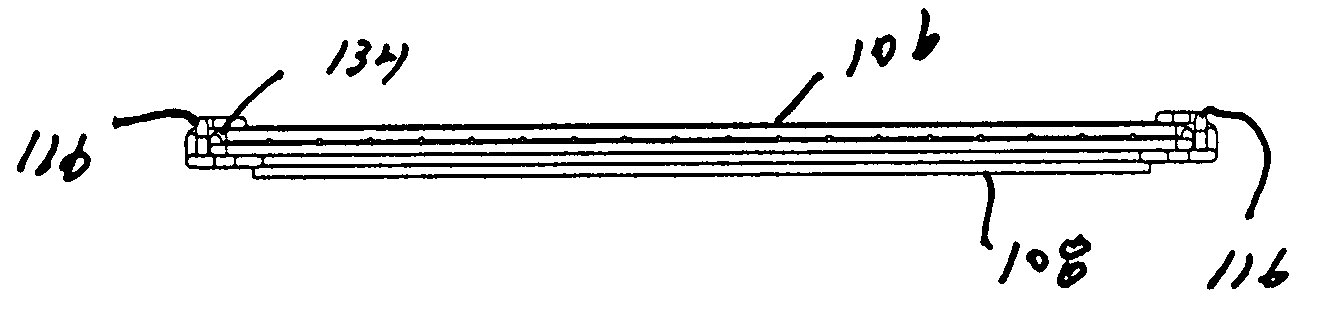

[0048] Parallel to the rear brace 106 and extending transversely across the base rack 104 near its middle and substantially near its front are a pair of transverse supports 108. Correspondingly, a pair of lateral supports 110 are also provided. The...

second embodiment

[0057] a slide rack in accordance with the invention is illustrated in FIGS. 13-24, and is identified as two piece oven rack 160. The two piece oven rack 160 is shown in the drawings as utilizing sheet metal components, rather than wire. Also, the two piece oven rack 160 has a slightly different configuration than the two piece oven rack 100 previously described herein. Both oven racks, however, provide for extension of a cooking rack relative to a base rack, and also provide a stop mechanism for the cooking rack during extension. It should also be mentioned that the oven racks may have various finishes, including, but not limited to nickel and porcelain. Also, as previously described, each of the oven racks may utilize a handle or the like, including the handle identified in U.S. Provisional patent application Ser. No. 60 / 496,885. Still further, the oven racks 100 and 160 may be utilized in conventional ovens, traditional household ranges, commercial ovens, barbeque grills and simi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com