Container configured for controllably dispensing flowable materials having a relatively thick consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

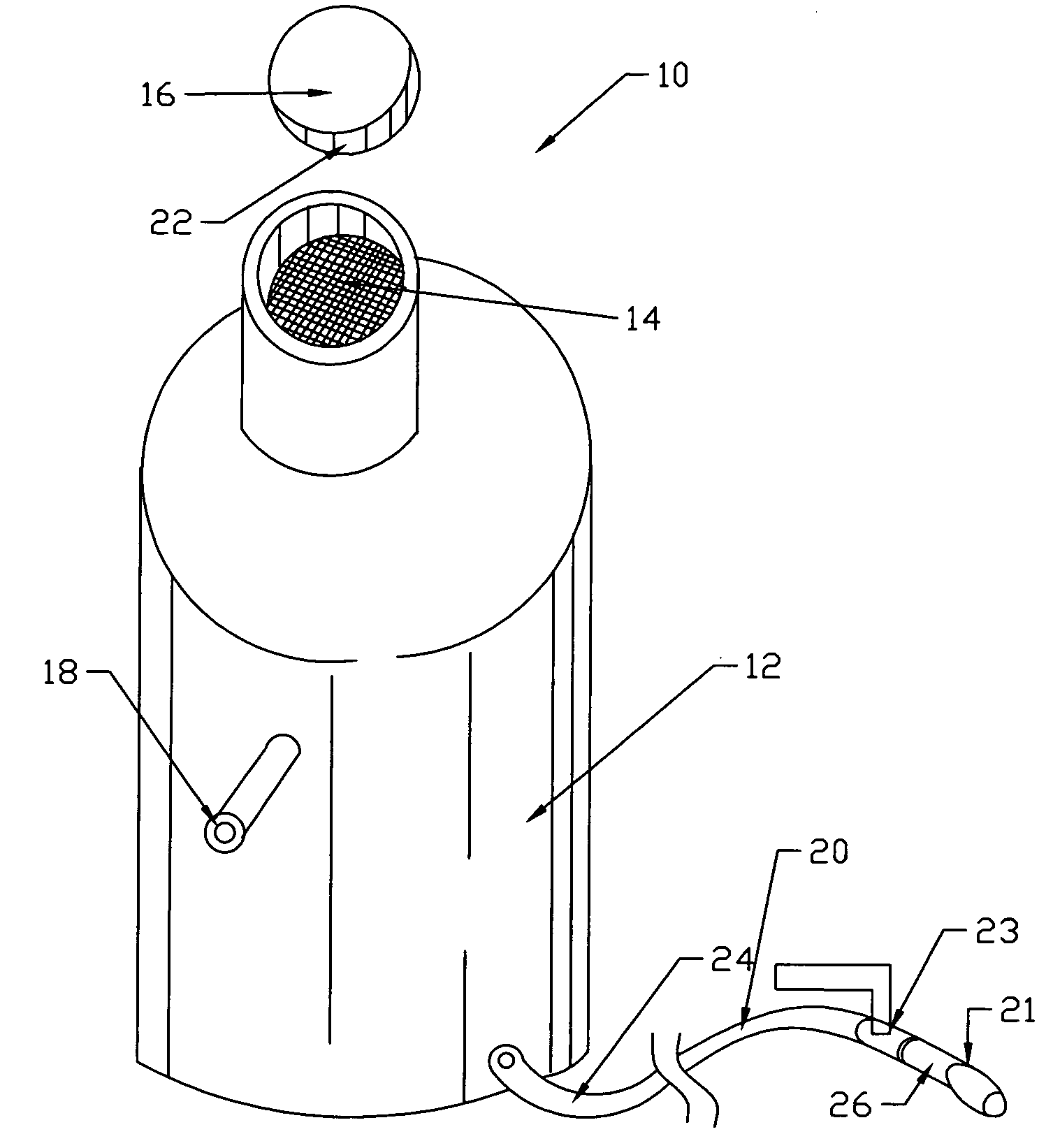

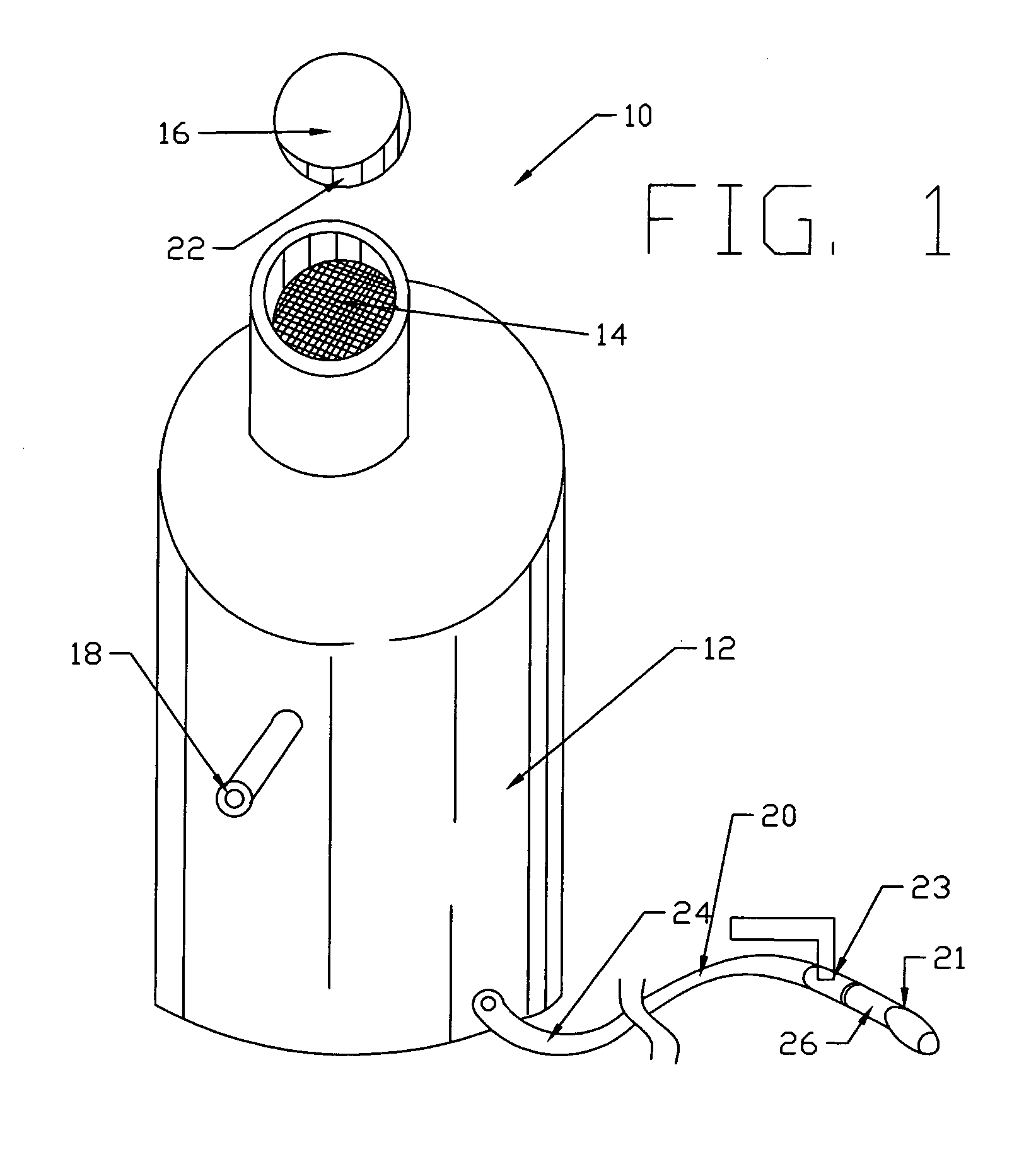

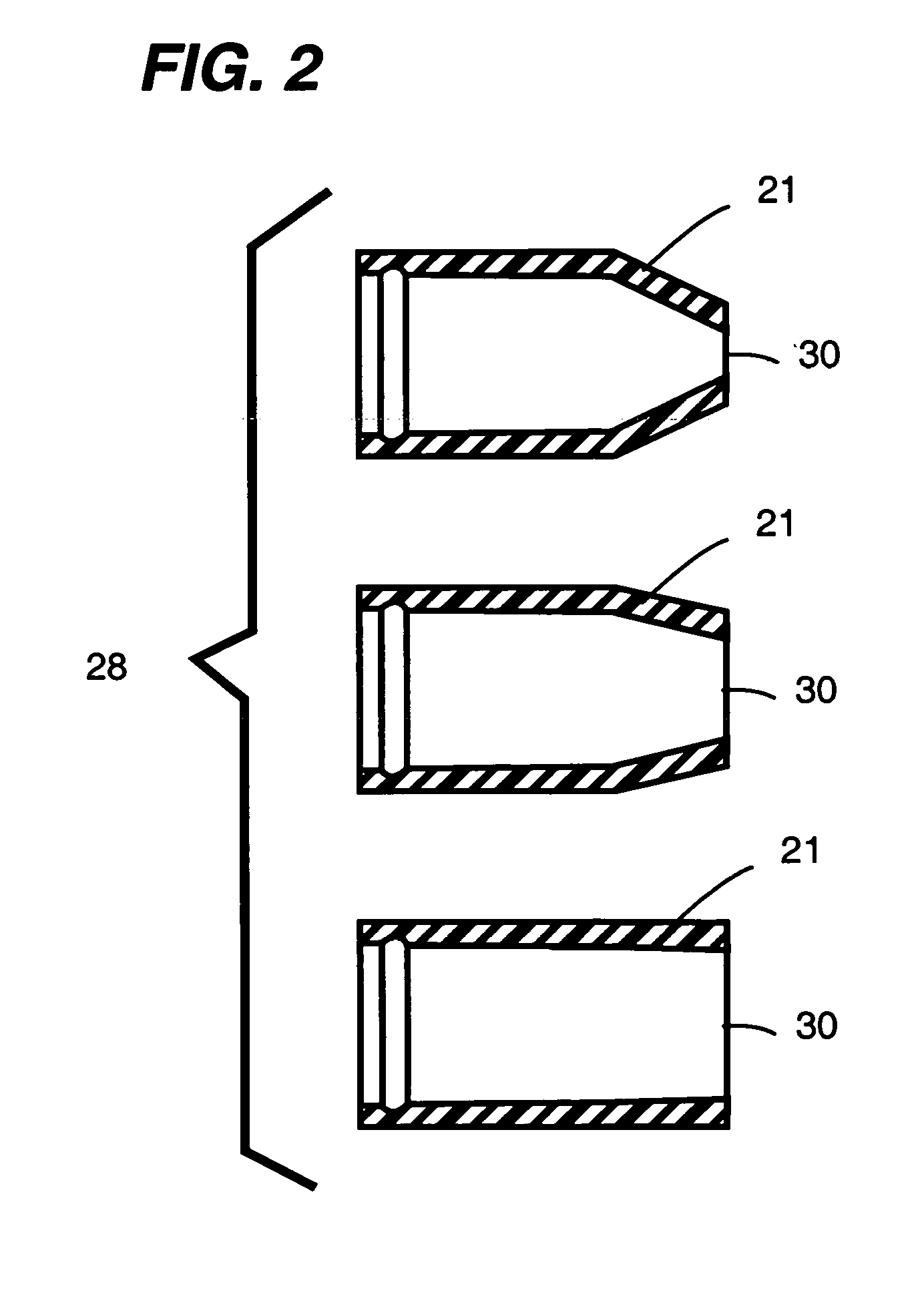

[0018]FIG. 1 depicts an embodiment of an apparatus 10 configured for dispensing flowable materials in accordance with the inventive disclosures made herein. The apparatus 10 includes a canister 12, a straining member 14, a lid 16, an air hose coupling 18, a dispensing tube assembly 20 and a dispensing tip 21. Preferably, but not necessarily, the canister 12, the straining member 14, the lid 16, the air hose coupling 18, the dispensing tube assembly 20 and the dispensing tip 21 are discrete components that are configured for being interconnected. In one example, the canister 12, the straining member 14, the lid 16, the air hose coupling 18 and the dispensing tube assembly 20 are respectively configured for enabling the straining member 14, the lid 16, the air hose coupling 18 and the dispensing tube assembly 20 to be attached to the canister 12. Similarly, the dispensing tube assembly 20 and the dispensing tip 21 are preferably, but not necessaril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com