Brushless motor pump

a brushless, motor technology, applied in the direction of piston pumps, pump control, fluid engines with non-positive displacement, etc., to achieve the effect of smooth operation and discharge of water, and minimal power us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Before the present invention is described in greater detail, it should be noted that like elements are denoted by the same reference numerals throughout the disclosure.

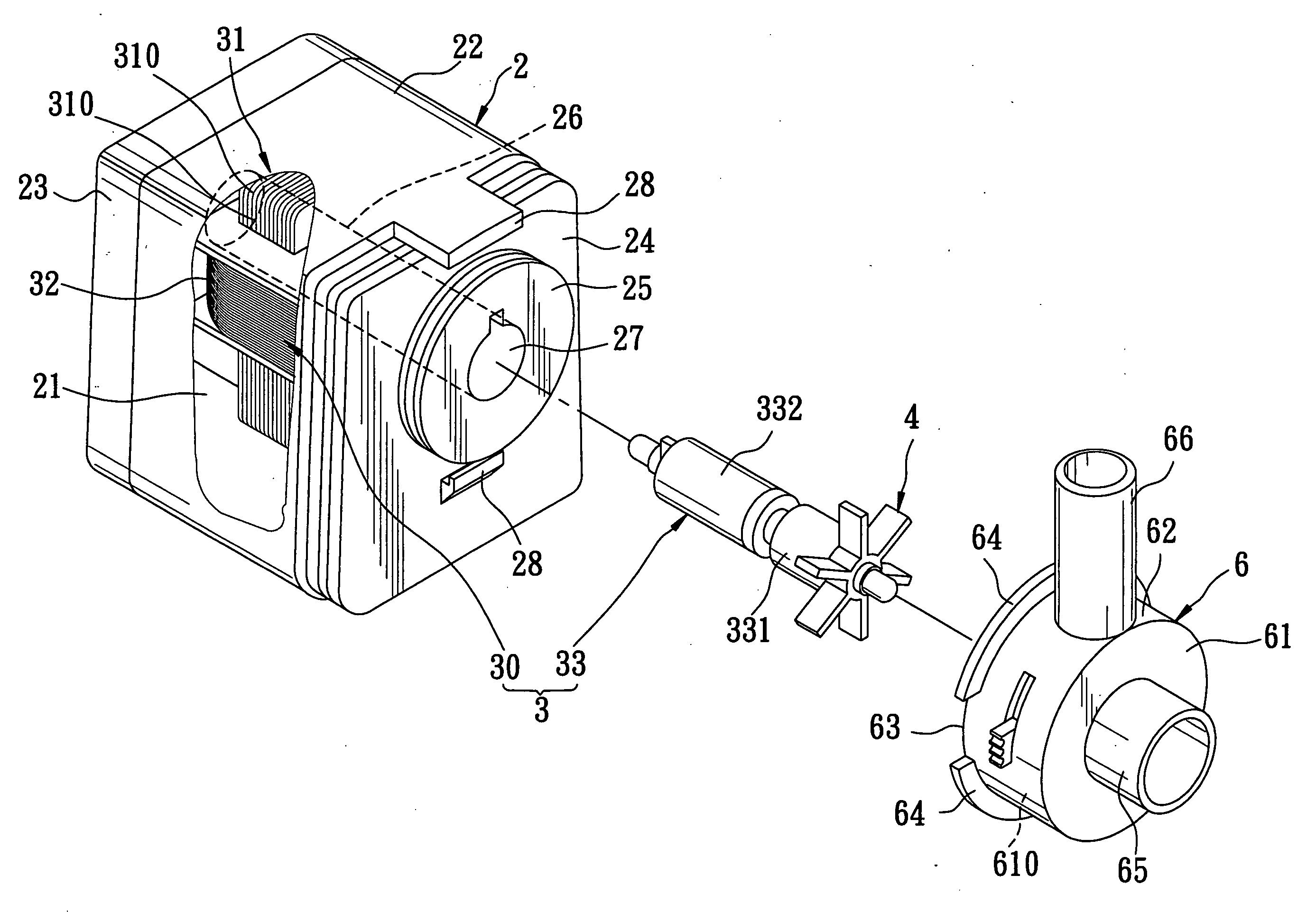

[0032] Referring to FIGS. 5 and 6, a brushless motor pump according to a first preferred embodiment of the present invention includes a case 2, a motor 3, a rotary blade assembly 4, a control unit 5, and a blade housing 6. The brushless motor pump may be a single-phase brushless motor pump.

[0033] The case 2 includes a main housing 22 that defines a chamber 21 therein. The main housing 22 has a rear end that is open, and a front end that is closed to form a front face 24. The case 2 also includes a rear cover 23 sealing the open rear end of the main housing 22. A circular boss 25 projects from the front face 24 of the main housing 22, and an opening is formed in the circular boss 25. A cylinder 26 is extended into the chamber 21 from the circular boss 25 starting from the opening 27. A pair of connectors 28 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com