Nanoparticle based inks and methods of making the same

a nanoparticle and ink technology, applied in the field of nanoparticles and inks, can solve the problems that colorants tend to bleed when applied to fabrics, colorants cannot be applied to colorants on a particular substrate in general, etc., to achieve the effect of stabilizing colorants, enhancing substrate independent durability performance of inks, and improving water and detergent resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

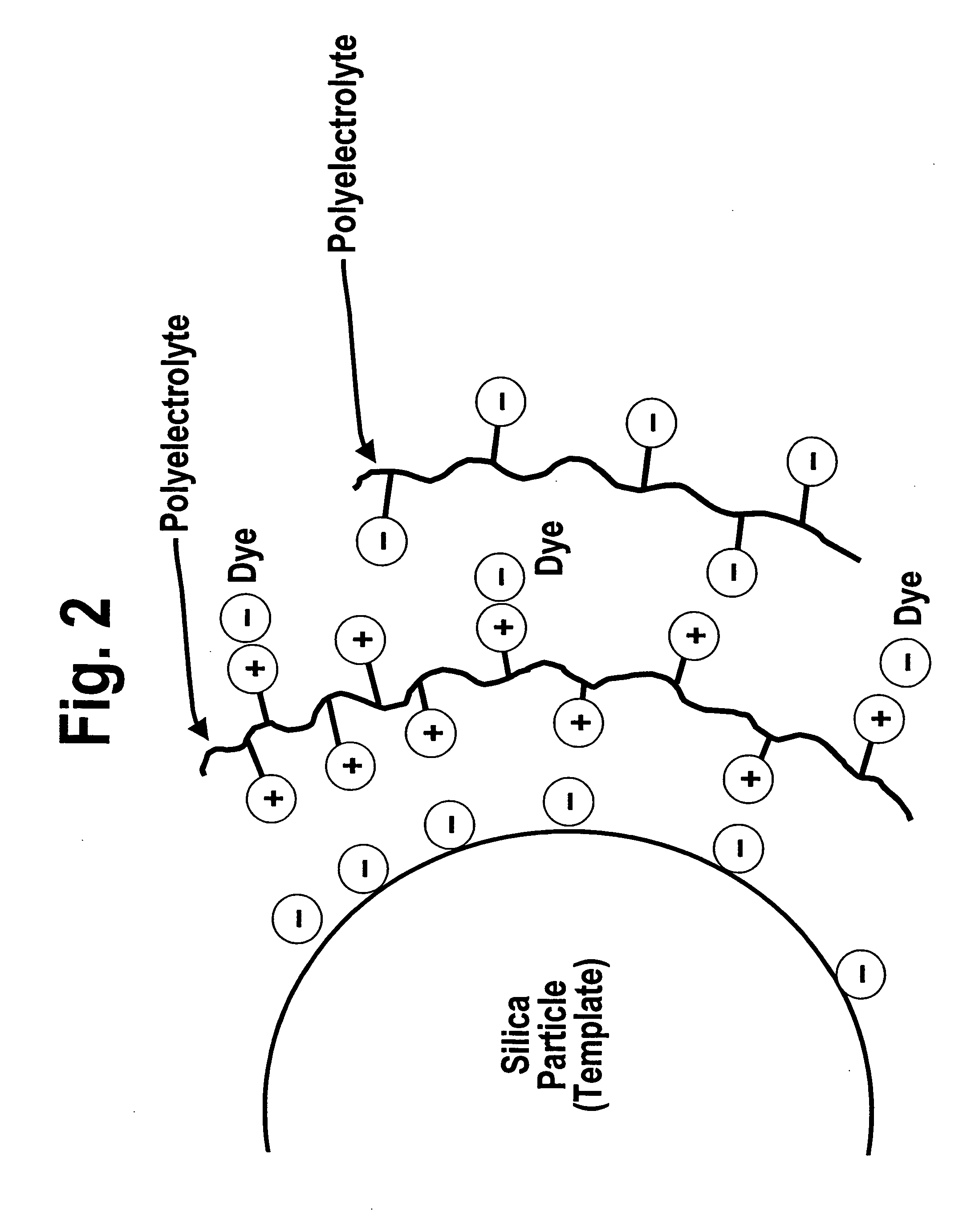

Preparation of Polyelectrolyte-Magenta Dye-Coated Silica Nanoparticles

[0101] A charged polymer-dye solution was first prepared as follows. A 20 mL sample of 10−2 M poly(butyl acrylate-methacryloxyethyl trimethylammonium bromide charged polymer was stirred while a solution of 0.06 g of acid red 52 (AR52) was added at room temperature. This solution was stirred for 20 min. The charged polymer-dye solution prepared in this fashion was then added to a suspension of 0.1% w / w colloidal silica (prepared from commercially available SNOWTEX™ C) which also contained 0.5 M NaCl. After this mixture was stirred for 20 min, the mixture was centrifuged (10,000 g) and the resulting magenta-colored powder was washed with water 3 times and centrifuged each time. The magenta powder from this experiment was suspended in water and placed in a dialysis bag overnight (ca. 16 h), with water as the partition. No dye was observed to diffuse out of the bag in this dialysis experiment.

example 2

Preparation of a Polyelectrolyte Coated Silica Nanoparticles

[0102] To a stirred suspension of 0.1% w / w colloidal silica (SNOWTEX™ C) in a 0.5 M salt solution was slowly added a 0.01 M charged polymer solution, comprising polybutyl acrylate-methacryloxyethyl trimethylammonium bromide. This mixture was centrifuged (10,000 g) and the resulting washed with water 3 times. This reaction generated a white powder comprising a charged polymer layered nanoparticle.

example 3

Dialysis Control Experiment

[0103] To examine a control dialysis experiment to compare with the results in Example 1, a solution containing only Acid Red 52 dye (AR52) was placed in a dialysis bag overnight with water as a partition. In contrast to the nanoparticle suspension dialysis experiment in Example 1, dye was observed to dialyze out of the bag overnight (ca. 16 h) in this control.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com