Volume maintaining osteoinductive/osteoconductive compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

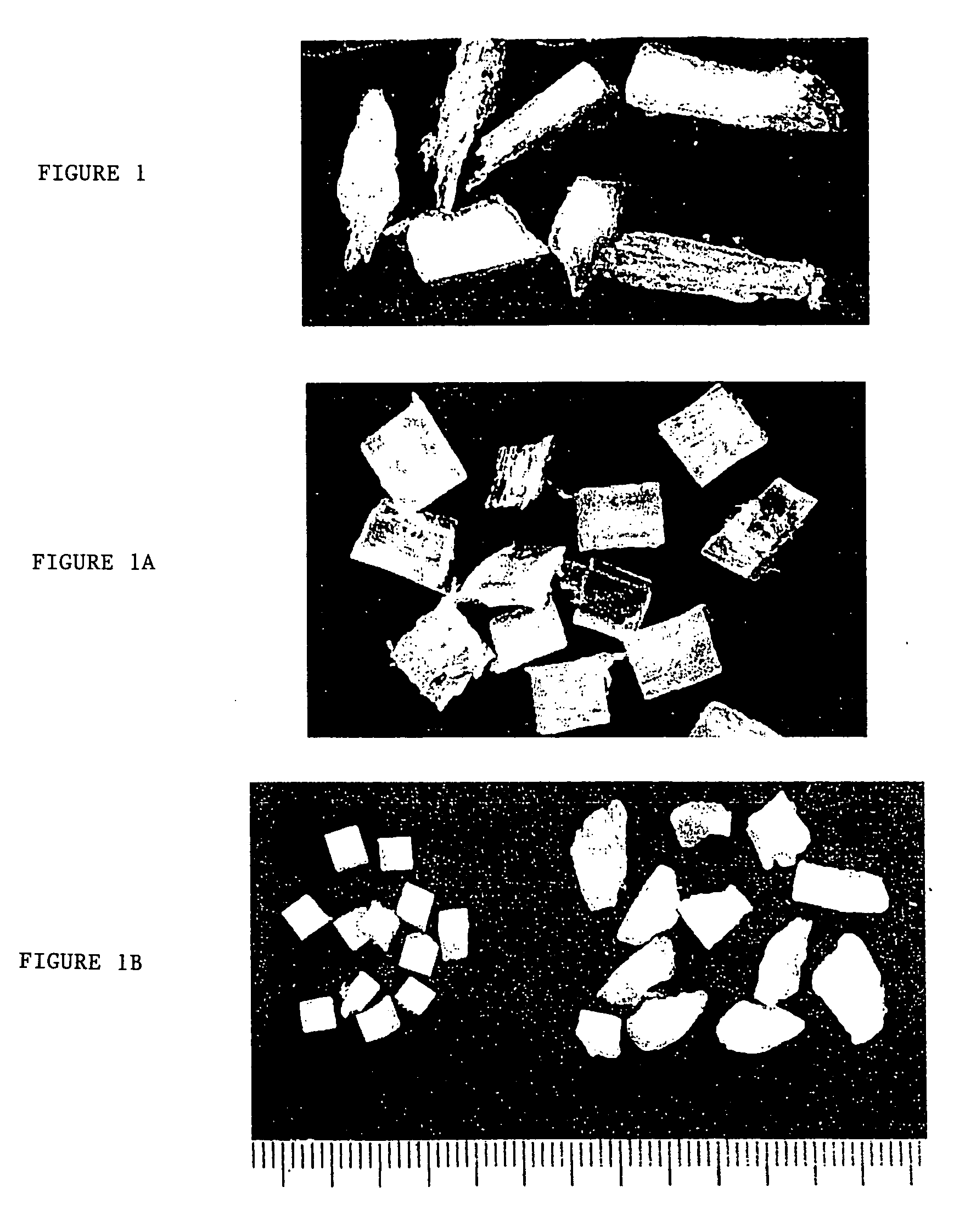

[0057] Sections of defatted, disinfected allogenic cortical bone approximately 210-250 mm in length were cut on a band saw to yield 145.65 g of cuboid non-fibrous bone elements about 3 mm in size. The remaining allogenic cortical bone was processed in the bone milling apparatus described in U.S. Pat. No. 5,607,269 to yield 145.8 grams of fibrous bone elements. The non-fibrous bone elements were then placed in a reactor. A 0.6 N solution of HCl at 15 ml per gram of non-fibrous bone elements was introduced into the reactor, the reaction proceeded for 1 to 2 hours. Following drainage of the HCl, the non-fibrous bone elements were covered with 0.6 N HCl / 20 ppm-2000 ppm nonionic surfactant solution for 24 to 48 hours. The fibrous bone elements were then added to the reactor and allowed to soak for 5 to 10 minutes. Following drainage of the HCl / surfactant solution, 0.6 N HCl at 15 ml per gram of total bone was introduced into the reactor, the reaction proceeded for 40 to 50 minutes. Follo...

example 2

[0058] The compressive force of the composition prepared as in Example 1 was compared with that of a like quantity of an osteoinductive / osteocondu-ctive composition prepared in accordance with U.S. Pat. No. 5,073,373 and an osteoinductive / osteoconductive composition prepared in accordance with U.S. Pat. No. 5,314,476. In this example, 5 cc of each material was placed into separate 10 cc syringe barrels. The compressive force (i.e., the sustained force capable of deflecting a meter probe) was then measured using the meter, to determine deflective force. The results are contained in the following table.

MaterialCompressive Force (N)U.S. Pat. No. 5,073,3734.8U.S. Pat. No. 5,314,4767.9Example 110.3

example 3

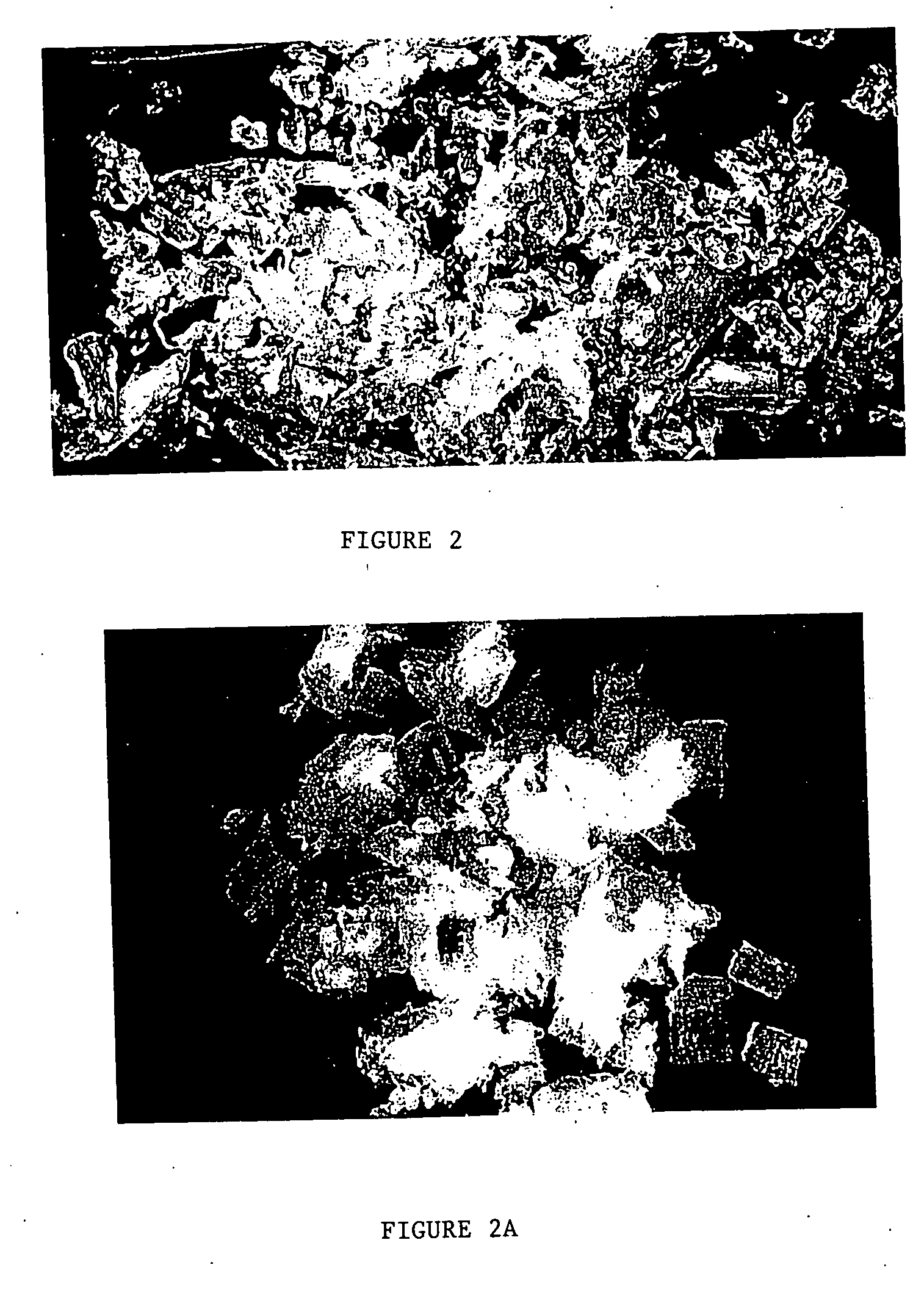

[0059] Material prepared as in Example 1 was evaluated to determine its osteoinductive potential. The material was implanted in female athymic homozygous mu / mu rats according to the procedure described in Edwards et al., Osteoinduction of Human Demineralized Bone: Characterization in a Rat Model, Clinical Orthopedics and Related Research (No. 357, pp. 219-228) 1998, the contents of which are incorporated hereby by reference. The material was studied to analyze its bone formation response. After 28 days in the rat model it was determined that cells had accumulated in the porous region inside of the chips, differentiated into bone forming cells, and were in the process of laying down bone in remodeling the matrix from the inside out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com