Apparatus and method for placement of a water closet fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

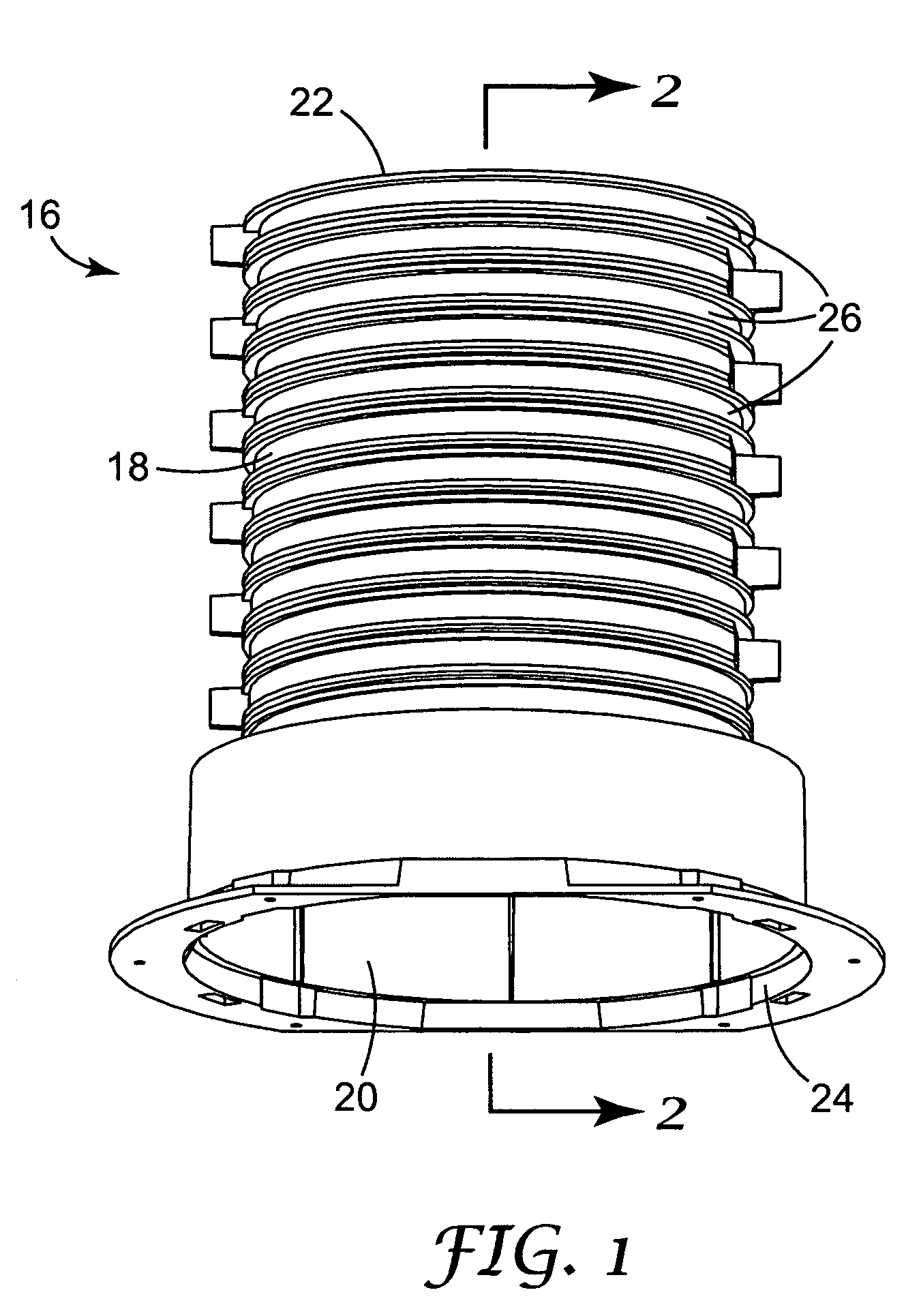

[0022] The present invention includes a water closet fitting for mounting to a channel extending through a concrete floor upon which a water closet is to be installed. The channel accommodates fluid connection means for connecting the water closet to a waste pipe of a plumbing system. FIGS. 1-2 show an example of a caste-in-place channel body 16 configured to form such a channel, with FIG. 1 showing a perspective view of channel body 16 and FIG. 2 showing a sectional view of channel body 16 taken along line 2-2 of FIG. 1.

[0023] Channel body 16 includes annular sidewall 18 that defines passage 20 having inlet 22 and outlet 24. As shown in FIGS. 1 and 2, sidewall 18 of channel body 16 includes a series of bands 26 which may be selectively removed to alter the length of passage 20. This variable length feature allows channel body 16 to be installed in floors of different thickness. Further description of channel bodies similar to channel body 16 is included in U.S. Pub. No. 2004 / 00161...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com