Cartridge, and toner container

a toner container and cartridge technology, applied in the field of toner containers and cartridges, can solve the problems of poor effect of enhancing the rigidity of the cleaning frame member, low rigidity of the periphery, and limited joint position in relation to space, and achieve the effect of wide joint surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0063] (Joining of Cleaning Frame Member and Drum Bearing; Embodiment 1)

[0064]FIG. 4 is a perspective view showing in detail the relationship of attachment between the drum bearing 38 (first component part), which supports the photosensitive drum, and the cleaning frame member 13 (second component part). The attaching of the drum bearing 38 to the cleaning frame member 13 and the attaching of a unitized photosensitive drum unit D to the cleaning frame member 13 are specifically described below.

[0065] The drum bearing 38 is, as shown in FIGS. 4 and 5, integrally provided with a large-diameter protrusion 38a and a small-diameter protrusion 38b. This small-diameter protrusion 38b is connected with an end of a disk portion 38c at the middle of the large-diameter protrusion 38a in its axial direction (lengthwise direction). The cleaning frame member 13 is, as shown in FIG. 4, provided on a sidewall 13b thereof with a bearing attaching hole 13h into which an outer peripheral portion 38b2...

embodiment 2

[0098] (Joining of Toner Frame Member and Side Cover; Embodiment 2)

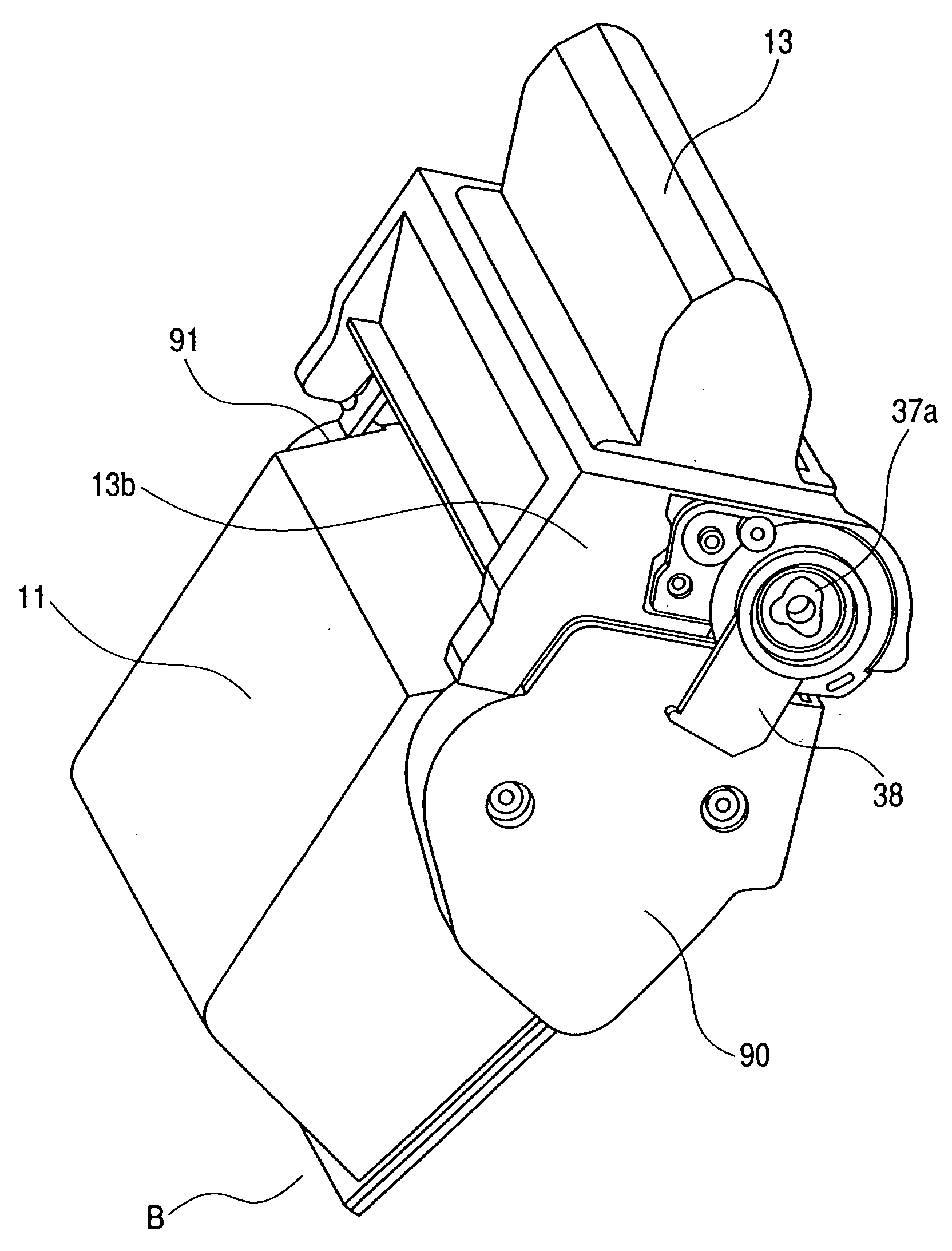

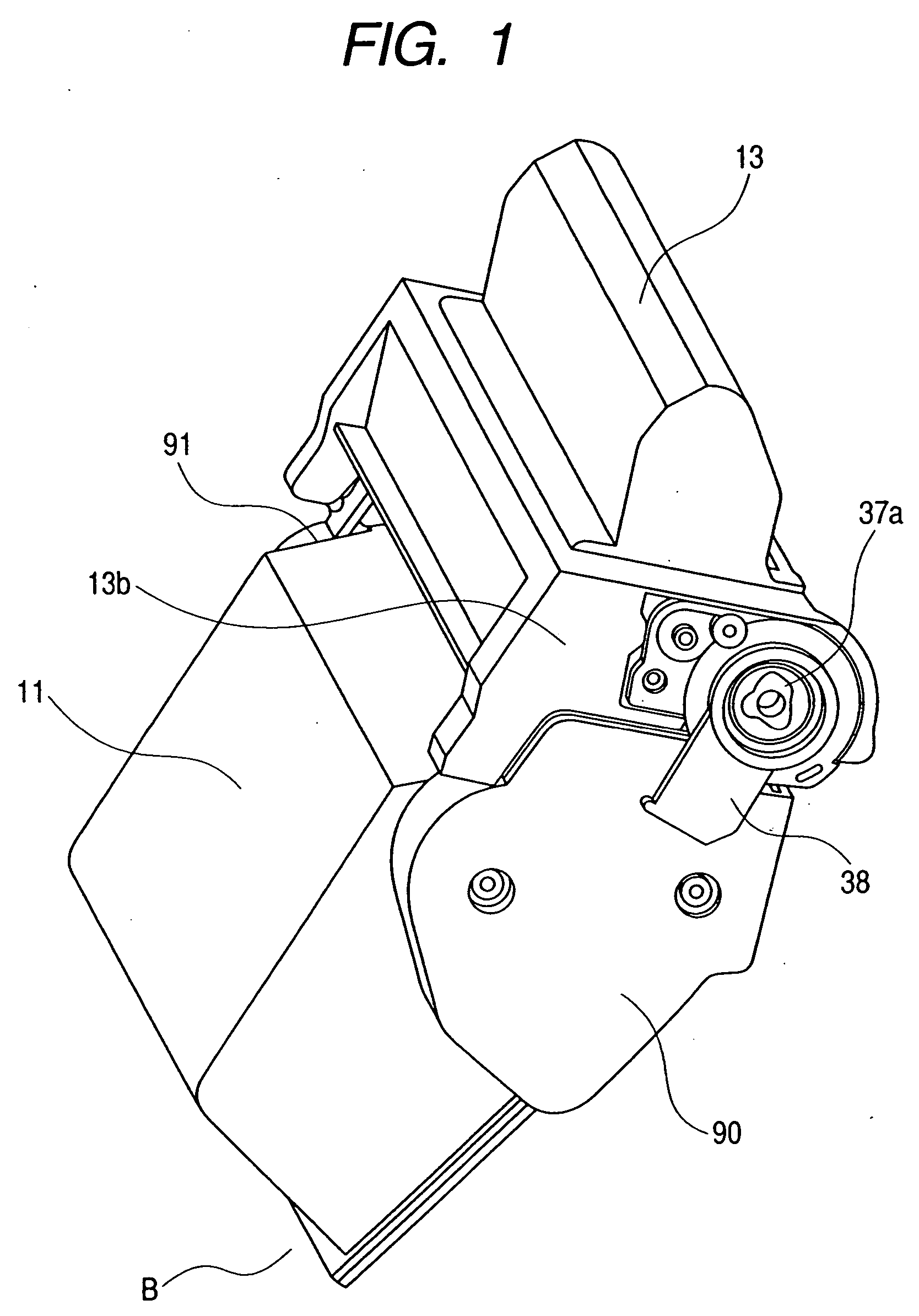

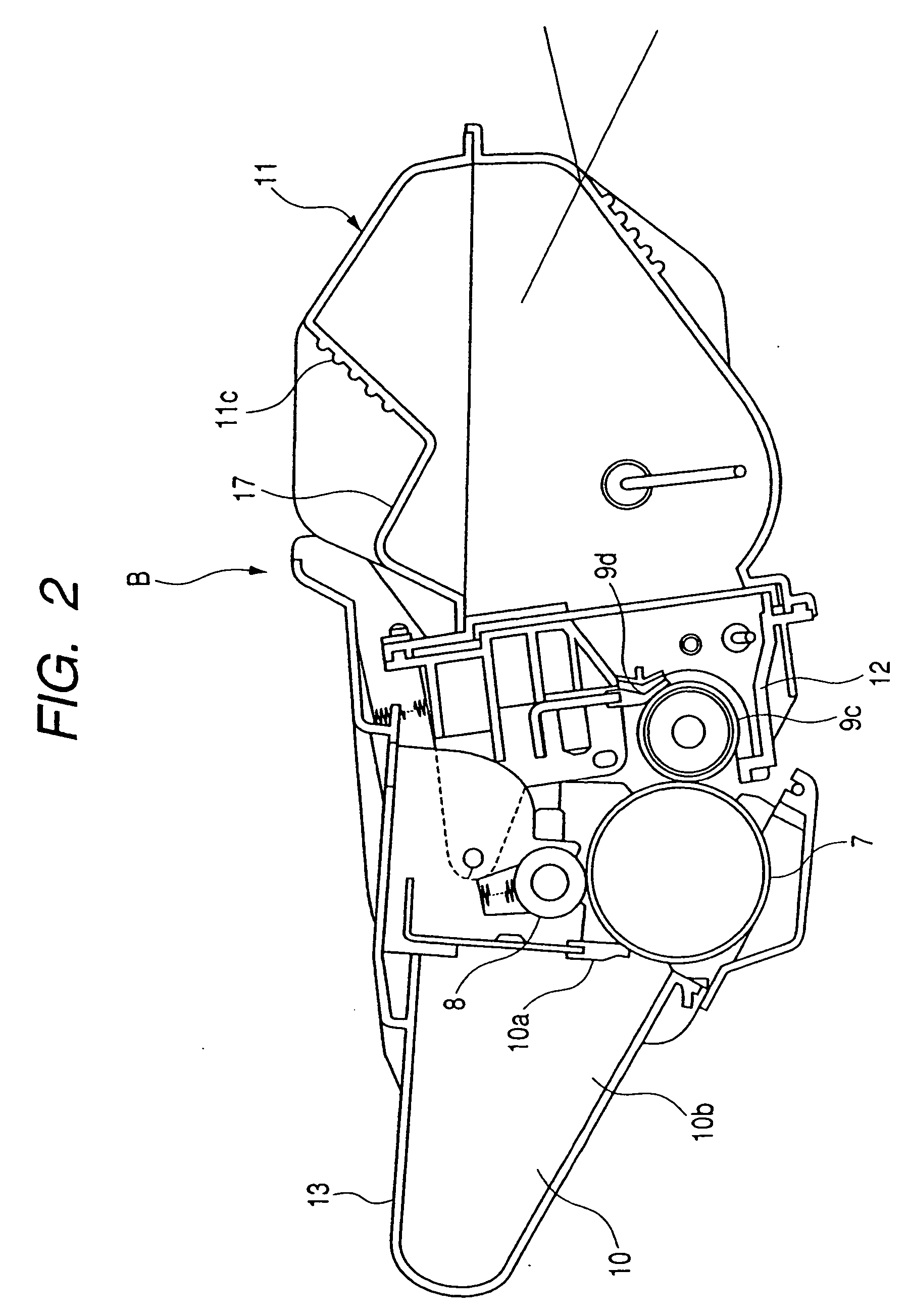

[0099] The joining of the toner frame member 11 and side covers 90 and 91 is described below (see FIGS. 1 and 12 to 14).

[0100] The toner frame member 11 described previously is provided with protrusions 50 and 51 for its positioning to the side cover 90(91: the side cover on the opposite side). Recesses 52 and 53 are also provided on the side cover 90(91) side correspondingly to the protrusions 50 and 51. As shown in FIG. 14, the protrusion 50 is fitted to the recess 52, where they serve as the center of rotation in the direction of an arrow g shown in FIG. 12, and the protrusion 51 is fitted to the recess 53, where they determine the rotational direction (position) of the toner frame member and side cover 90(91). Also, the positioning in the lengthwise direction is determined by making end faces 50a and 51a of the protrusions 50 and 51 come to the ends of the recesses 52 and 53 at their bottom faces 52a and 53a, re...

embodiment 3

[0111] (Joining of Toner Container Component Parts; Embodiment 3)

[0112] In the toner container having at least a first component part formed of a first styrene resin composition and a second component part formed of a second styrene resin composition, the first component part and the second component part were joined with the terpene type solvent (d-limonene). As a result, joining in a high positioning precision was achieved, and a toner container was obtained which was almost free of deformation at the periphery of the joint and had a high rigidity.

[0113] Incidentally, the terpene type solvent was fed by utilizing the capillarity. Also, HIPS (a styrene polymer mixed with 8% by weight of polybutadiene rubber having an average particle diameter of 0.8 μm) was used as materials for the respective component parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| average particle diameter | aaaaa | aaaaa |

| sectional area | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com