Washing machine having dynamic vibration absorber

a technology of dynamic vibration absorption and washing machine, which is applied in the direction of shock absorbers, other washing machines, mechanical equipment, etc., can solve the problems of generating a vibration level, excessive vibration of washing machines, and the inability to prevent the vibration of internal assemblies from being transmitted to the external structure, so as to reduce the vibration of washing tubs and reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Reference will now be made in detail to an illustrative, non-limiting embodiment of the present invention, an example of which is illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The exemplary embodiment is described below to explain the present invention by referring to the annexed drawings.

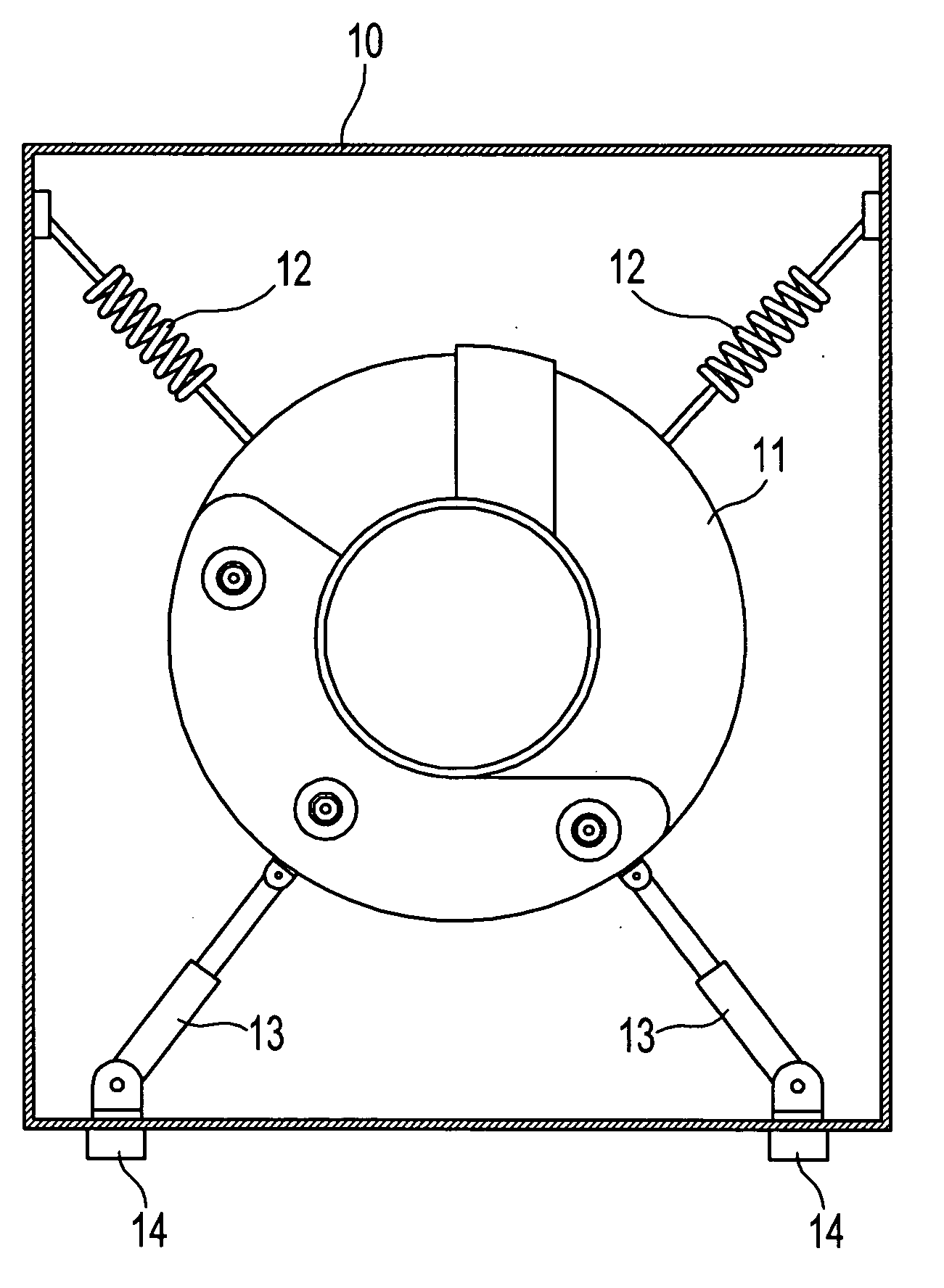

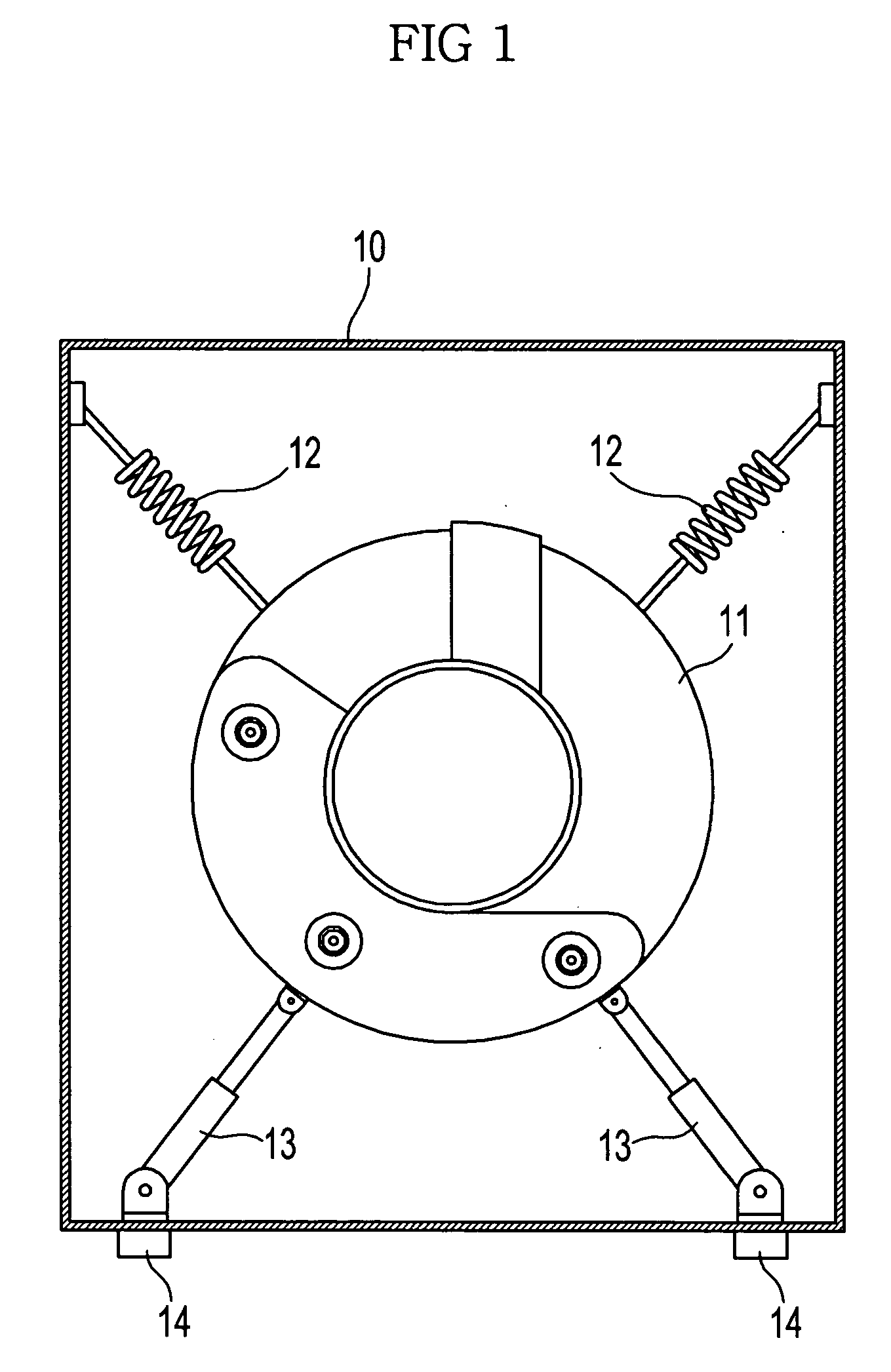

[0032] As shown in FIG. 3, a washing machine in accordance with an exemplary embodiment of the present invention comprises an external structure 10 serving as an external casing, an internal assembly including a washing tub 11 and a driving device (not shown) installed in the external structure 10, suspension springs 12 for elastically supporting the internal assembly, dampers 13 installed at the lower part of the washing tub 11 for reducing vibration of the washing tub 11, and mounts 14 formed on the bottom surface of the external structure 10. Here, elements, which are the same as or similar to those of the related art, are de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com