Method for delivering hot and cold beverages on demand in a variety of flavorings and nutritional additives

a hot and cold beverage and nutritional additive technology, applied in the field of delivering flavored or nutritionally enhanced hot and cold beverages, can solve the problems of increasing media pressure, time and labor consumption, and poor demand, and achieve the effect of convenient storage and selection, and easy customization by users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

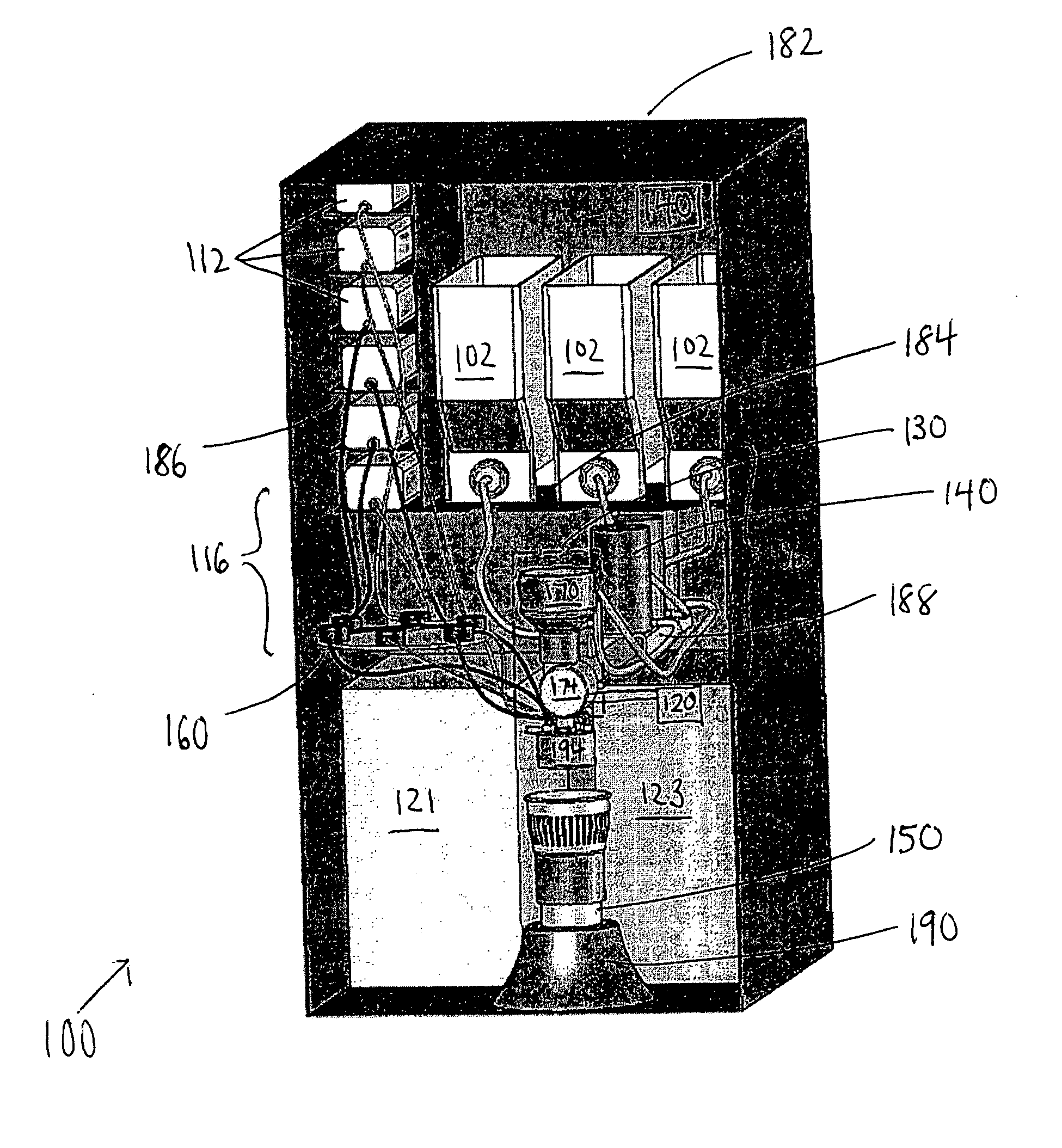

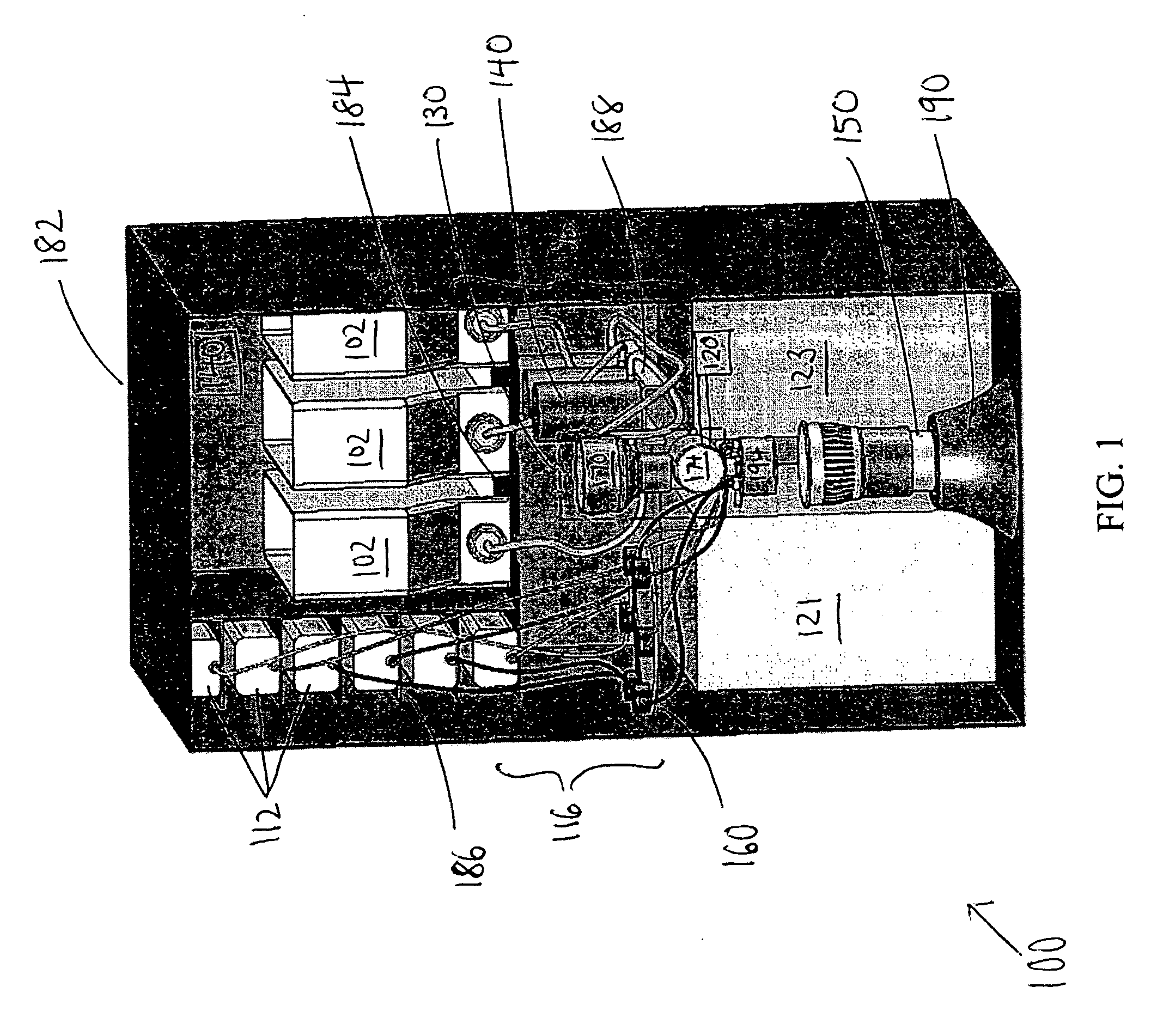

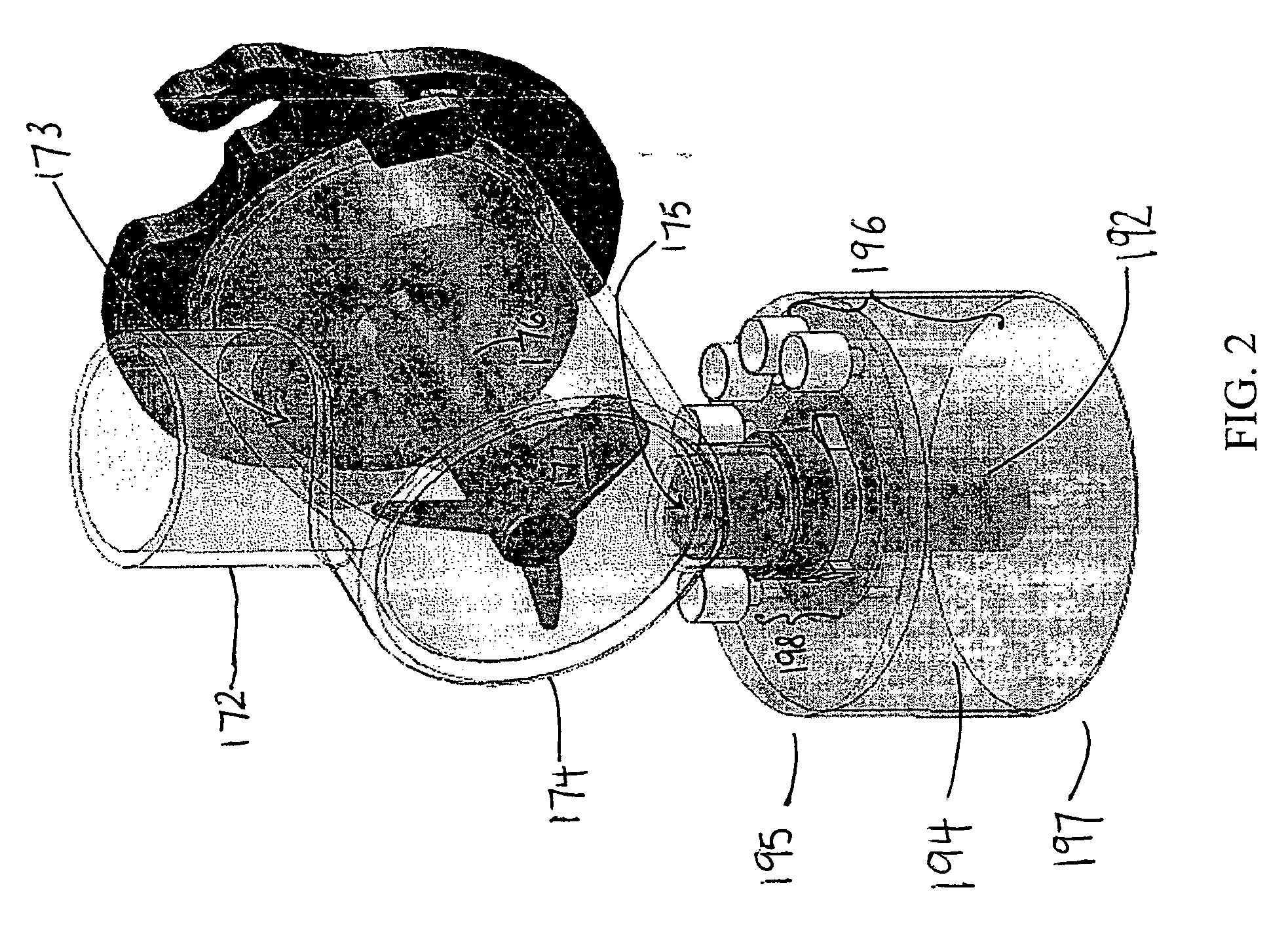

Image

Examples

examples

[0126] In the following examples, all percentages are expressed in weight.

[0127] One coffee-based liquid premix is made of the following:

Coffee solids 5-10%Non-dairy creamer15-30%Sweetener (sucrose)30-50%Flavors 1-5%Nutritional additives 1-2%

[0128] The water activity of the coffee-based liquid premix is less than about 0.85; pH is about 6-7 and total solids is about 67% to 75%.

[0129] The coffee-based liquid premix is heat treated under the following conditions: about 85-93° C. for about 30-90 seconds (non-UHT conditions) and packaged in a multilayer plastic pouch with a foil layer. The premix is stable during about 12 months at ambient conditions. The water activity should be low, i.e., less than about 0.85, with stabilizers to substantially prevent degradation of aroma, flavors, and physical stability. The packaging preferably protects the product from light and oxygen.

[0130] A cocoa-based liquid premix is made of the following:

Cocoa solids 5-10%Non-dairy creamer15-30%Sweete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com