Washing machine

a washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of increasing complicating the assembling process, and complicated tubs, so as to simplify the molding process of the tub, reduce the volume of the washing machine, and minimize the number of components and assembly steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

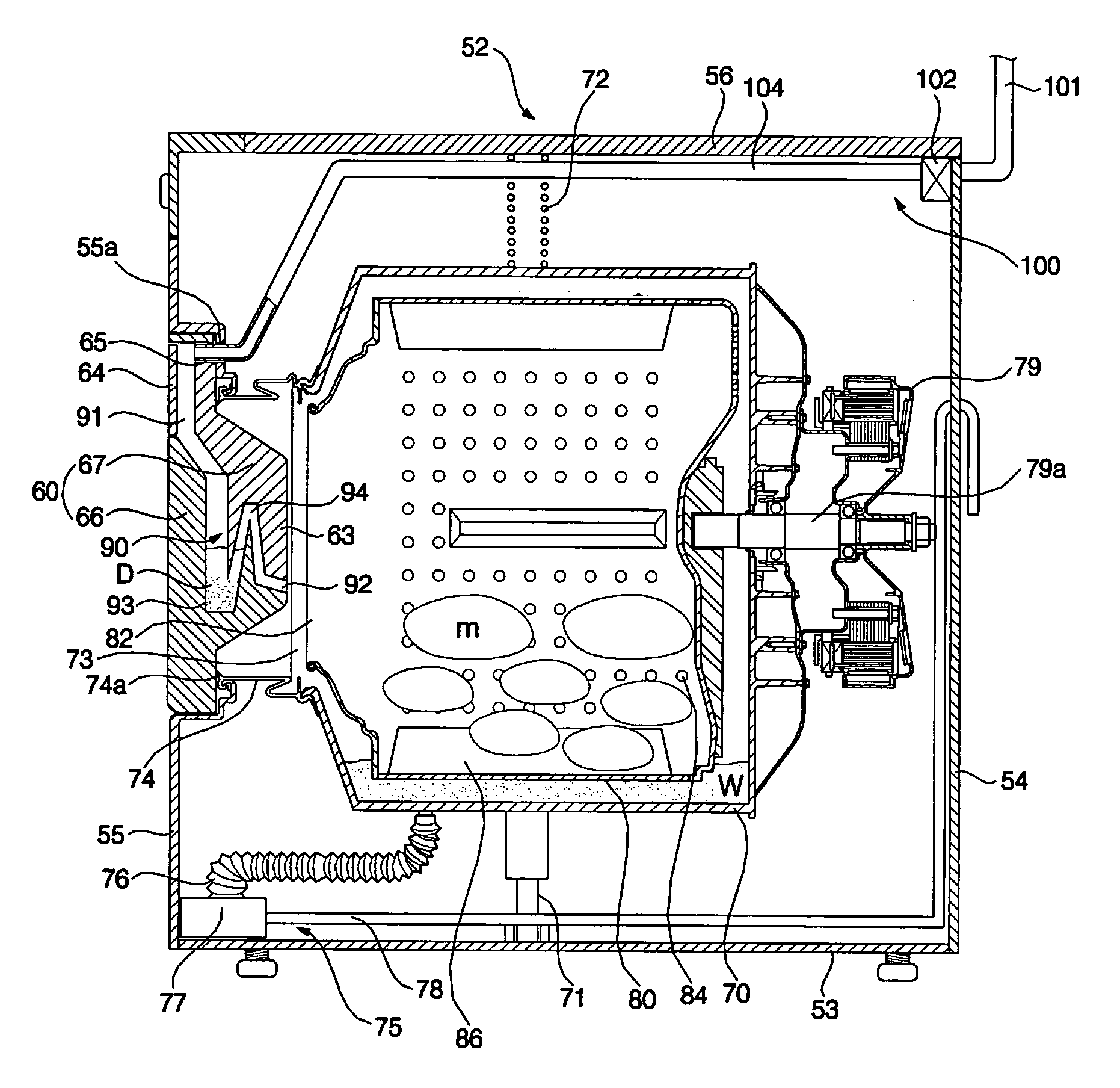

[0057] As shown in FIGS. 3 and 4, the washing machine comprises: a cabinet 52 having a laundry entrance 51 formed therein; a door 60 for opening / closing the laundry entrance 51; a tub 70 mounted within the cabinet 52; a drum 80 rotatably disposed within the tub 70 for containing laundry m; a detergent supply part 90 formed in the door 60; and a water supply device 100 disposed therein so as to communicate with the detergent supply part 90 when the door is closed in order to supply water to the detergent supply part 90.

[0058] The cabinet 52 comprises a base plate 53 constituting a bottom surface of the washing machine, a cabinet body 54 located on the base plate 53 to constitute lateral sides and a rear side of the washing machine, a cabinet cover 55 located at the front of the cabinet 54 to constitute a front side of the washing machine and having the laundry entrance 51 formed at the center of the cabinet cover 55, and a top cover 56 located on the cabinet body 54 to constitute a ...

second embodiment

[0105]FIG. 5 is a side sectional view illustrating the inner structure of a washing machine in accordance with the invention, and FIG. 6 is a perspective view illustrating the washing machine of FIG. 5, the door of which is opened.

[0106] As shown in FIGS. 5 and 6, the washing machine according to the second embodiment comprises a door 60′ which has an inlet 91′ of a detergent supply part 90′ formed at a rear side of the door 60′ such that detergent D is input through the inlet 91′ of the detergent supply part 90′ after opening the door 70′ in front of the washing machine. Other constructions and operations thereof are the same as those of the washing machine according to the first embodiment. Thus, the other constructions are denoted by the same reference numerals as those of the first embodiment, and a detailed description thereof will be omitted.

[0107] The door 69′ comprises a front panel 66′, and a rear panel 67′ coupled to a rear side of the front panel 66′, in which the rear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com