Cable binding band structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

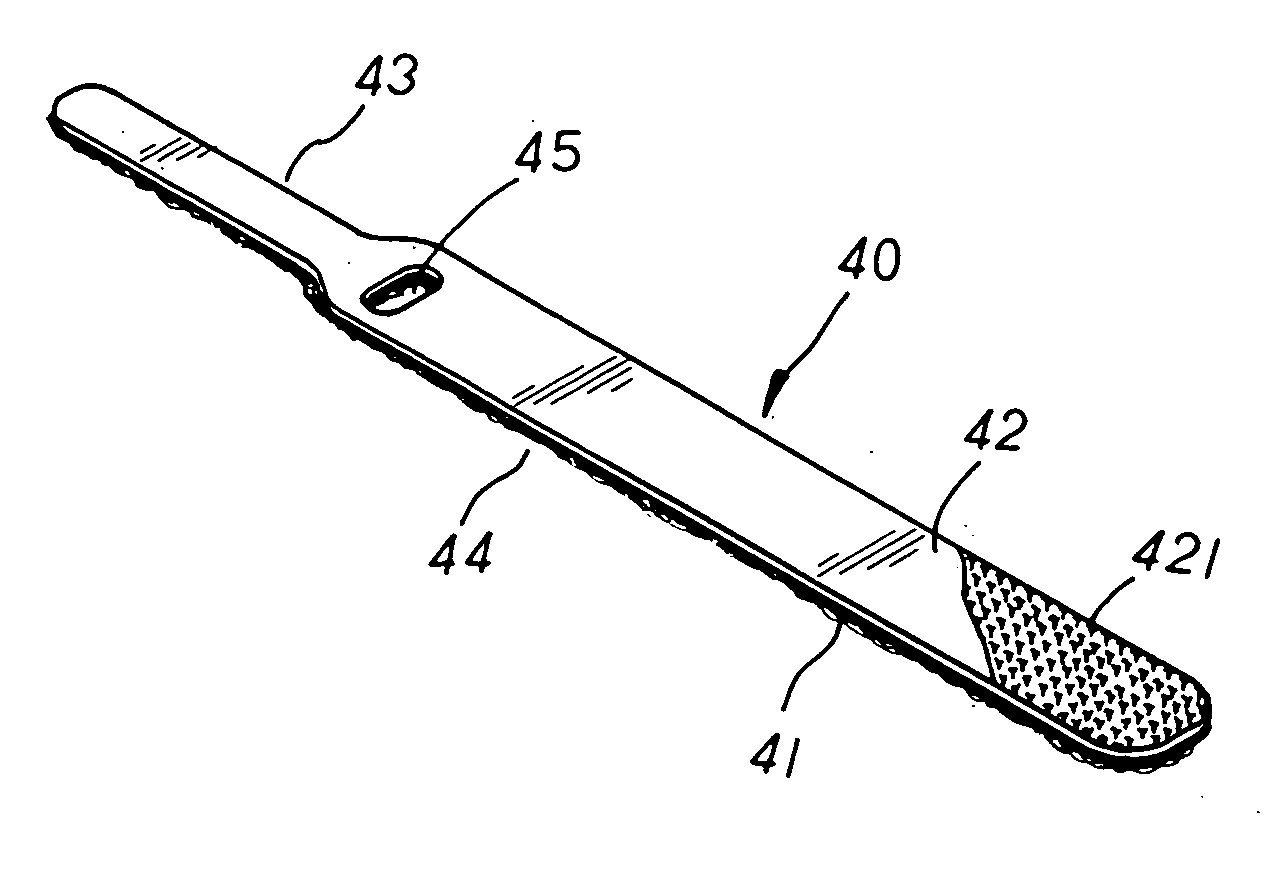

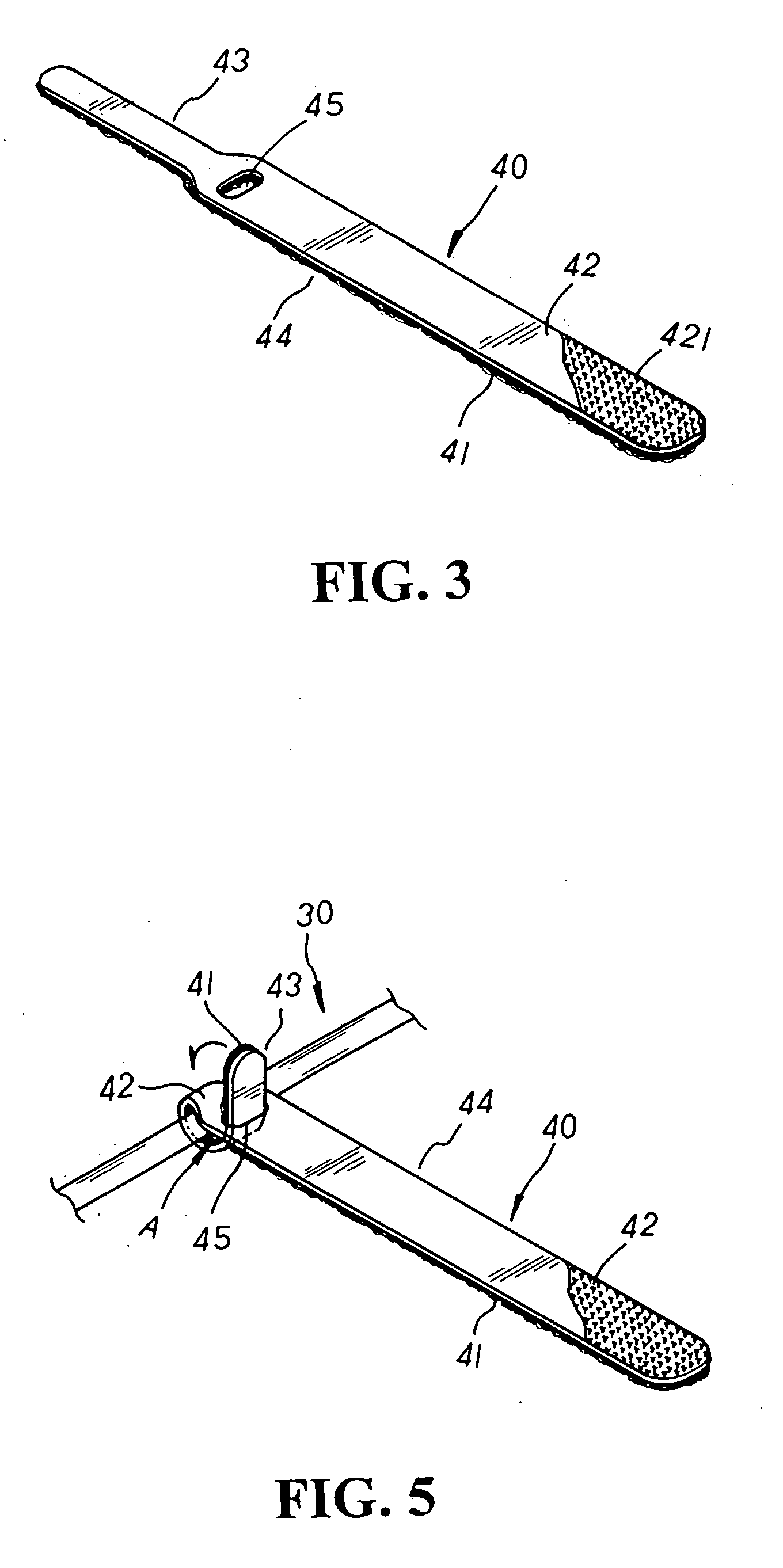

[0016] Please refer to FIGS. 3 to 4 inclusive. The present invention is related to a cable binding band structure, including a binding band 40 made up of a fleeced stick side 41 and a fastening hook side 42 with a plurality of protrusive fastener dots 421 distributed thereon as shown in FIG. 4. Both ends of the binding band 40 thereof are respectively defined by a narrowed retaining section 43 and a wide binding section 44, and the binding section 44 thereof has a through hole 45 properly disposed at a preset position thereon in matched cooperation with the retaining section 43 thereof.

[0017] Please refer to FIGS. 5 to 6 inclusive. In practical use, the retaining section 43 of the binding band 40 is directly wound around a cable 30 and inserted through the through hole 45 of the binding section 44 thereof. Then, the retaining section 43 protruding outside the through hole 45 thereof keeps winding downwards till the fleeced stick side 41 disposed at one surface of the binding band 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com