Optical fiber reel module and winding method therefor

a technology of optical fiber and reel module, which is applied in the direction of optical elements, instruments, optical waveguide light guides, etc., can solve the problems of high cost, deformation and/or damage of the coating of er doped optical fiber b>4/b>, and inability to adjust the high-precision amplification characteristic, so as to achieve the effect of reducing stress and high-precision amplification characteristic adjustmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Referring to FIG. 4, there is shown a sectional view of an EDF module 16 according to a first preferred embodiment of the present invention in the condition that the EDF module 16 is mounted on a metal reel 18. FIG. 5 is a cross section taken along the line V-V in FIG. 4. The metal reel 18 is composed of a first segment 20 having a center hole 22 and a second segment 24 having a shaft 26 inserted in the center hole 22 of the first segment 20. A resin reel 28 having elasticity is mounted on the metal reel 18. The resin reel 28 is formed of silicone rubber, fluororubber, or soft polyvinyl carbazole (PVC), for example. The resin reel 28 is fabricated by using a mold so that the outer diameter of the bottom of the resin reel 28 becomes 60 mm.

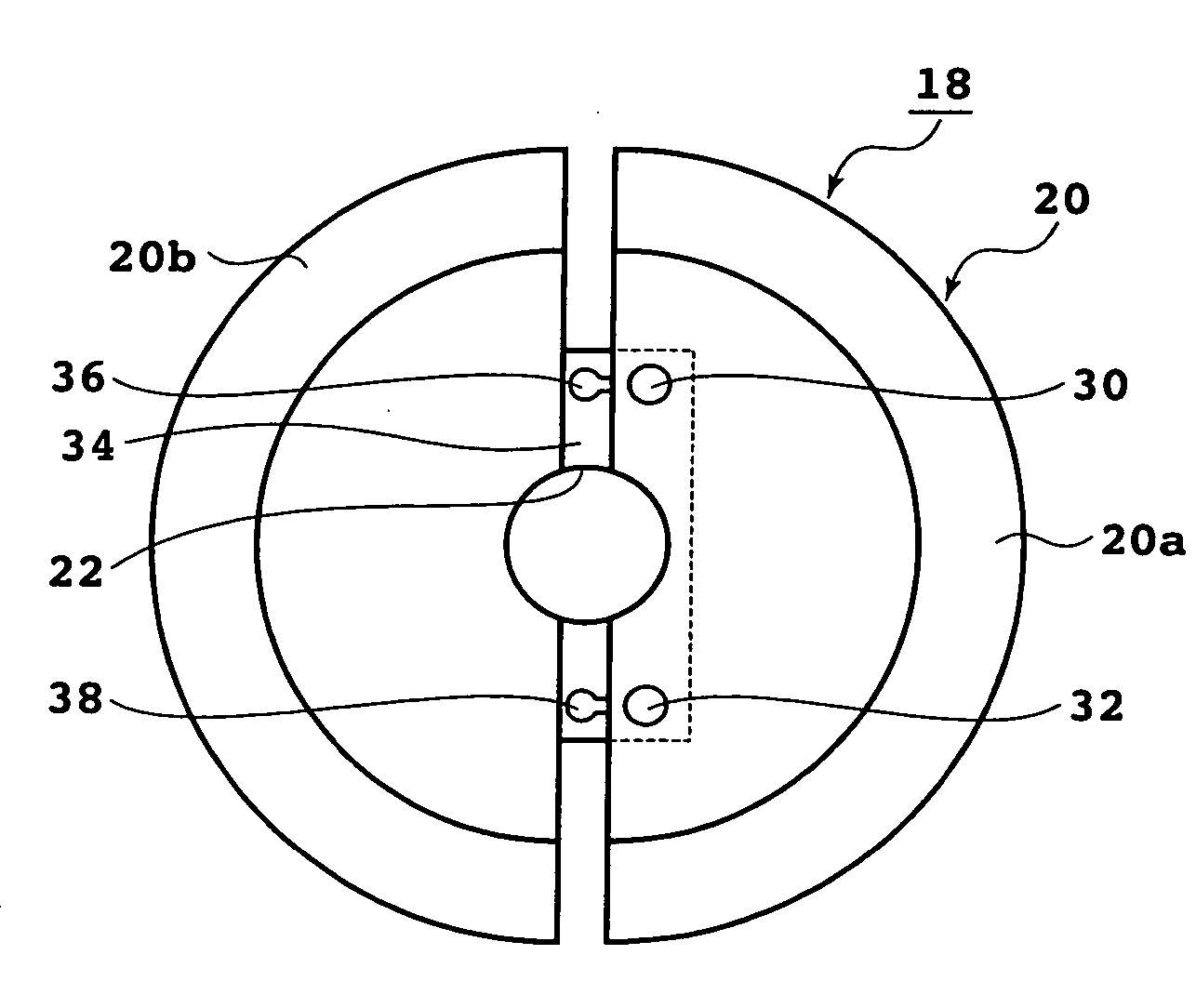

[0026] As shown in FIG. 6, the first segment 20 of the metal reel 18 is composed of a first semicircular reel 20a and a second semicircular reel 20b. A pair of pins 30 and 32 are fixed to the first semicircular reel 20a. The second semicircu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com