Process and apparatus for making a sheet of aramid fibers using a foamed medium

a technology of aramid fibers and foamed medium, which is applied in the field of foaming, can solve the problems of inefficiency of processes and sheets lacking uniformity, and achieve the effect of improving the integrity of sheets and being effective and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

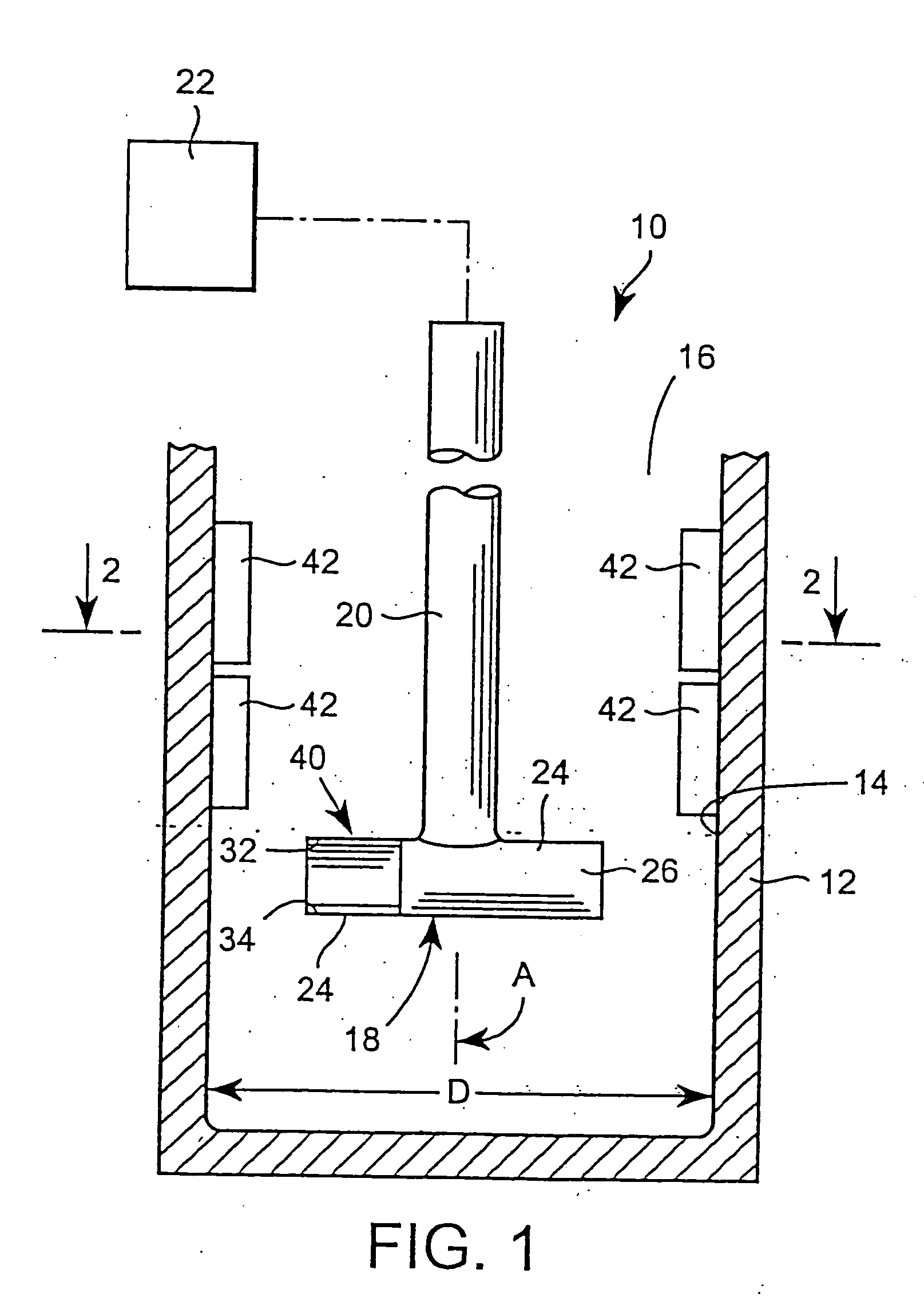

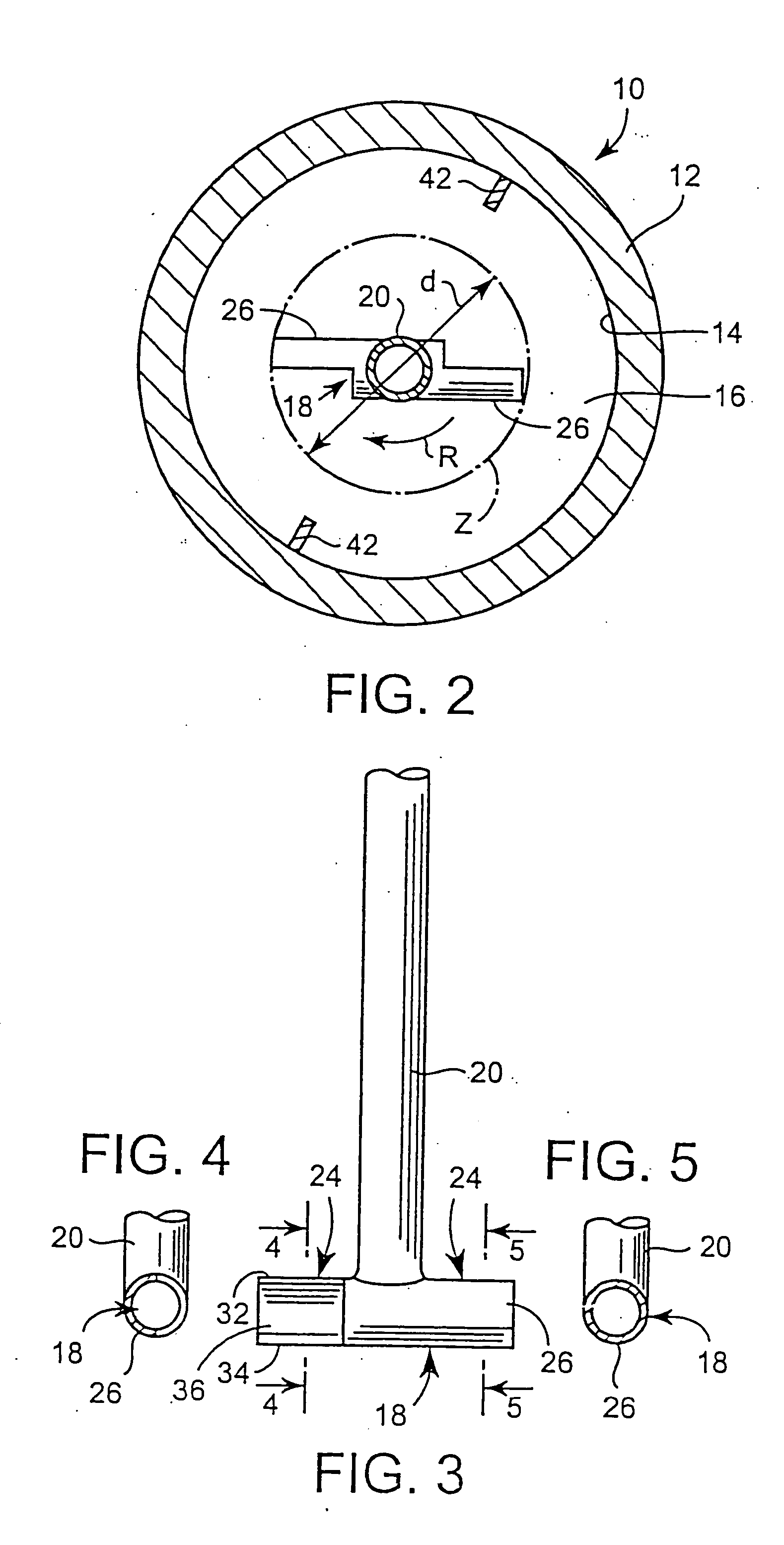

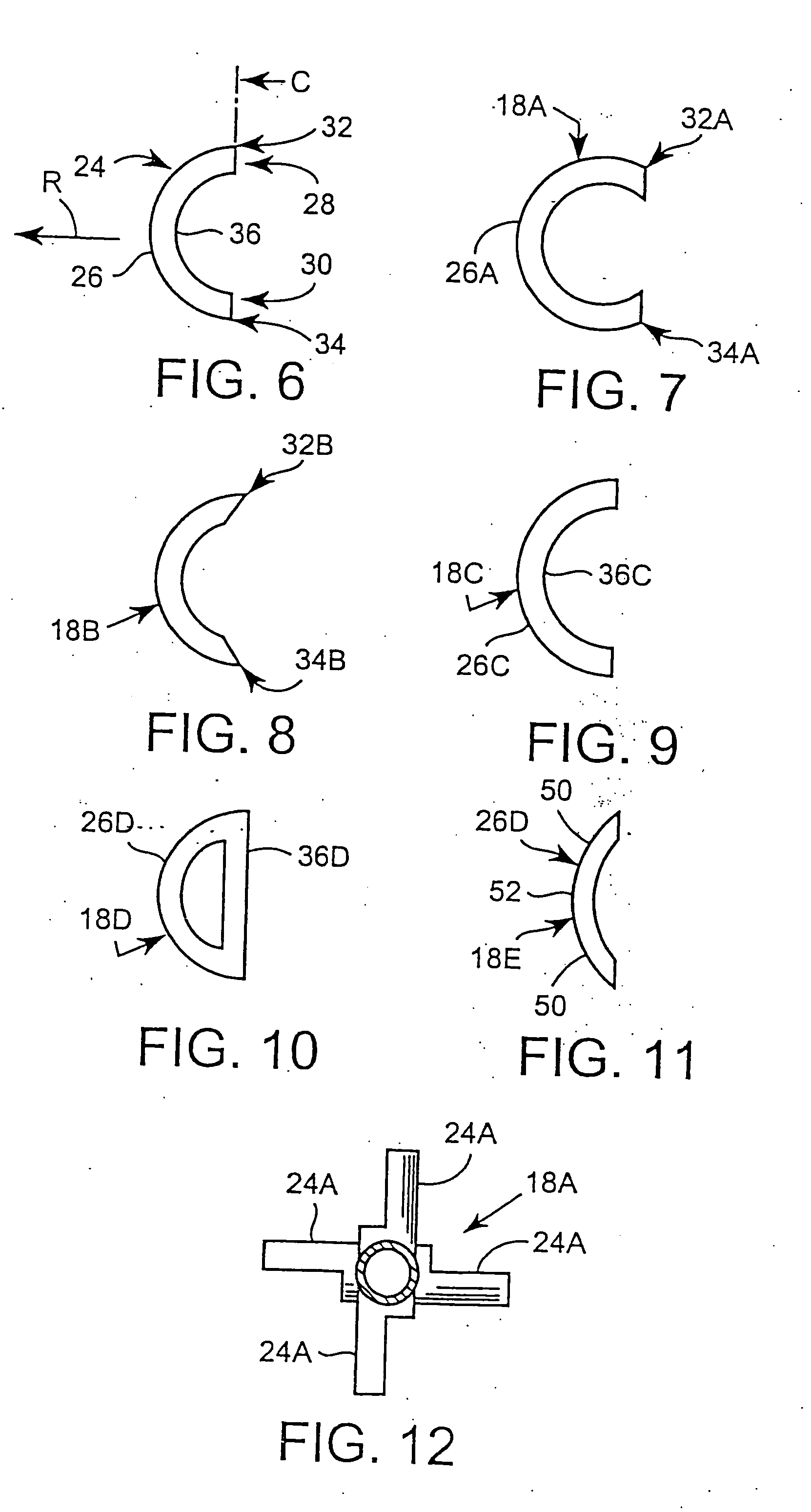

[0022] The process of the present invention comprises the steps of first forming a foam furnish by agitating a fiber mixture comprised of up to 100% of aramid fibers, in a foamed medium with the agitation apparatus of the present invention, and then passing the foam furnish onto a screen, e.g., a wire or plastic fabricated screen, and defoaming the furnish. Preferably, the furnish will also contain aramid fibrid. The aramid fibrid is a small irregularly shaped piece of aramid, e.g., Nomex®, polymer that is much larger in two dimensions than it is in the third dimension. It is like a microscopic corn flake in shape. The large dimensions are on the order of 5 to 25 micrometers, while the third and smaller dimension is about 0.01 to 1 micrometer. The fibrid can serve as a bonding agent for the aramid fibers in the final web, and thus greatly enhances the integrity of the final web. The agitating apparatus used in the process is depicted in the Figures of the Drawing, and can be describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com